الحار منتجات

ملكنا الإخبارية

km mine belt conveyor cost-Conveyor Technology in Mining Conveyors

Evaluating rules of thumb using conveyor

2020年5月1日As a rule, a belt conveyor operation is more economical than truck haulage if the conveying distance exceeds 1 km (3,280 ft.). (Source: Heinz Altoff) 3. The ton

Conveyor systems QueensMineDesignWiki

Brief History on Conveyor SystemsTypes of Conveyor SystemComponents in A Conveyor SystemDesign of A Conveyor SystemTechnical Design of A Conveyor SystemMaintenanceFactors Effecting ReliabilityConveyor System CostsWorks Cited

Conventional Mining ConveyorThe conventional conveyor is the most common conveyor system, uses two or more pulley systems with a belt that rotates about them, carrying medium. The two pulleys can be powered for certain requirements in the conveyor system. The conventional conveyor belt is ‘v’ shaped to beGravity ConveyorSimilar to the conventional mining conveyor, the gravity conveyor is a two pulley system. However, gravity conveyors travel on a decline benefiting from potential energy. This belt turns a motor within a generator storing electricity as ore is transported. Depending on the height and st在minewiki.engineering.queensu.ca上查看更多信息

Analysis of Conveyor Drive Power

2020年12月9日This article presents the analysis of conveyor drive power requirements for three typical mining conveyors. One of the conveyors was found not to be

BELT CONVEYOR 911Metallurgist

2021年5月8日Estimated operating maintenance cost per year for a belt conveyor is 2% of the purchase cost plus

Mining Conveyor Belts [Competitively Priced] West River

2023年3月1日Tensile strength, impact absorption and wear characteristics are

HOW MUCH DOES AN OVERLAND (SURFACE)

2021年5月17日A VFD starter for the system described could cost $50k-$60k. In the

A technical look at conveyors Canadian

2016年5月1日The longest (belt) conveyor system in the world is in Western Saraha. It’s 98-km long and runs from the phosphate mines of Bu Craa the coast south of El-Aaium.

Latest Developments in Belt Conveyor Technology

Although belt conveyors have always been an efficient Skyline Mine in UT, USA

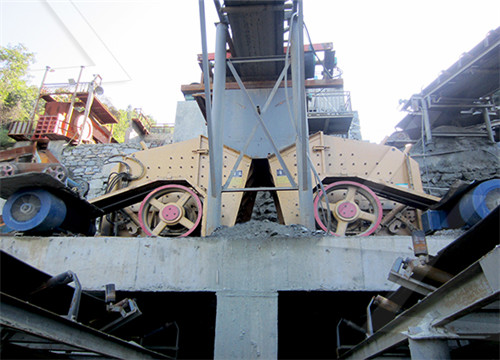

Mining and Aggregate Overland Conveyor Cost Per Mile

It is a typical overland conveyors mining solution for large scale mine plant. We can

Belt conveyor systems Crushing and

Creating a drive system for multiple conveyor belts requires in-depth know how. Our offering, based on our experience applying solutions on more than 600 kilometers of belt

Mining Industry: Bulk Handling and

Our systems easily master steep inclines, rivers, and roads. Coal, ores, and minerals can be transported on the conveyor belt from the mine to the blending bed in just one hour,

Belt Conveyors for mining applications

Belt Conveyors for mining applications Belt Conveyors for mining applications Belt conveyor systems continuously transport all forms of material, including

What Does An Underground Conveyor System Cost? West River Conveyors

2021年6月3日Cost depends on belt width, (mining belts usually range from 36-60”), strength (expressed in pounds per inch of belt width (PIW), and the number of plies. Depending on these variables, an underground conveyor belt costs between $25-$100/ft. DISCHARGE UNIT/ROCK BOX/TRANSFER CHUTE

Mining and Aggregate Overland Conveyor Cost Per Mile

SKE is a professional overland conveyor manufacturer in China. We can help you do the preliminary research on your project and design the overland conveyors mining system for transporting bulk materials. You can get overland conveyor rollers, overland conveyor belts, overland conveyor driving pulleys, overland conveyor bending pulleys, overland

Latest Developments in Belt Conveyor Technology

Although belt conveyors have always been an efficient Skyline Mine in UT, USA (Figure 12). This 3.38 km Latest Developments in Belt Conveyor Technology MINExpo 2004, Las Vegas, NV, USA

Innovative conveyor belt monitoring with belt damage detection MINING

2023年3月1日Prevention of unplanned conveyor downtime; Transparent data assessment; This is made possible by the perfect interplay of our existing and new modules. The advantage of our system is installation of conveyor belt monitoring on any conveyor in the bulk goods sector with relatively little cost and effort. The modules. Scraper

Belt conveyor TTC-9-12 TTC Mühendislik powder /

Belt conveyors are machines that undertake the task of transporting bulk materials from fixed feeding locations to certain places and perform this task non-stop. If thousands of tons of bulk materials per hour need to be transferred to a different location, the use of belt conveyors is the only option. Especially in mines, iron and steel

Pipe Conveyors for Bulk Materials Beumer Conveying Technology

Highly economical with low investment costs. Low-wear construction with a lengthy service life even with highly abrasive materials. Energy recovery option. Centre distance: up to 10 km. Performance: up to 10,000 t/h. Conveying speed: up to 6.5 m/s. Angles of inclination: up to 30° depending on the material to be conveyed.

Conveyor systems QueensMineDesignWiki

Technology now allows conveyors to easily span lengths of 20 km 30 km, with the longest system reaching 100 km (SME, 2011) . Types of Conveyor System Conventional Mining Conveyor System (Belterra Corperation, 2014) Conventional Mining Conveyor

How to optimize energy efficiency in conveyor operations

2020年9月14日Our well researched and patented Energy Saving Idlers ® (ESI) conveyor component helps boost the energy efficiency for overland conveying solutions in mining applications. With over 30 years of industry experience, Metso Outotec has found a way to provide up to 30% power savings, depending on each conveyor profile, for material

Belt conveyor systems Crushing and

Creating a drive system for multiple conveyor belts requires in-depth know how. Our offering, based on our experience applying solutions on more than 600 kilometers of belt

Mining conveyor systems ABB conveyor

Mining conveyor systems are getting larger, more durable and going underground One major trend that has the potential to boost the market for large conveyor

Mining Industry: Bulk Handling and

Our systems easily master steep inclines, rivers, and roads. Coal, ores, and minerals can be transported on the conveyor belt from the mine to the blending bed in just one hour,

Latest Developments in Belt Conveyor Technology

Although belt conveyors have always been an efficient Skyline Mine in UT, USA (Figure 12). This 3.38 km Latest Developments in Belt Conveyor Technology MINExpo 2004, Las Vegas, NV, USA

Mining and Aggregate Overland Conveyor Cost Per Mile

SKE is a professional overland conveyor manufacturer in China. We can help you do the preliminary research on your project and design the overland conveyors mining system for transporting bulk materials. You can get overland conveyor rollers, overland conveyor belts, overland conveyor driving pulleys, overland conveyor bending pulleys, overland

Machine Learning Based Fault Detection on Belt Conveyor Idlers

2023年3月2日Belt conveyors are used extensively in the mining industry. Faults in their components can compromise the entire plant production. Machine learning-based techniques have been applied successfully

Improving Mining Operations With Smart Technology West River Conveyors

2021年10月29日Examples of Smart technology at work in mining include: Monitoring and early detection of belt tracking issues Measuring current drawn by a motor to monitor load Observing temperatures in electrical control cabinets to detect overheating Recording vibration in shafts and bearings and comparing this with baseline data to detect wear

Pipe Conveyors for Bulk Materials Beumer

Highly economical with low investment costs. Low-wear construction with a lengthy service life even with highly abrasive materials. Energy recovery option. Centre

Innovative conveyor belt monitoring with belt damage detection MINING

2023年3月1日Prevention of unplanned conveyor downtime; Transparent data assessment; This is made possible by the perfect interplay of our existing and new modules. The advantage of our system is installation of conveyor belt monitoring on any conveyor in the bulk goods sector with relatively little cost and effort. The modules. Scraper

Belt conveyor TTC-9-12 TTC Mühendislik powder /

Belt conveyors are machines that undertake the task of transporting bulk materials from fixed feeding locations to certain places and perform this task non-stop. If thousands of tons of bulk materials per hour need to be transferred to a different location, the use of belt conveyors is the only option. Especially in mines, iron and steel

Mining with a Heavy Industrial Conveyor

Our customers in the mining industry know they can count on MIPR Corp conveyor belts to keep the line moving in even the toughest conditions. It takes a tough constitution

How to optimize energy efficiency in conveyor operations

2020年9月14日Our well researched and patented Energy Saving Idlers ® (ESI) conveyor component helps boost the energy efficiency for overland conveying solutions in mining applications. With over 30 years of industry experience, Metso Outotec has found a way to provide up to 30% power savings, depending on each conveyor profile, for material

No problem with the curve: Rail running conveyor solutions

2020年5月15日Fugitive dust from conveyor transfer points. Mine layouts that are awkward or unfeasible for conventional trough conveyors. This new belt conveying technology allows a conveyor to run in a single flight from pit to plant along the curve of the haul road, hairpins excepted. Those estimates include the operating cost of feeding

Comprehensive Conveyor Belt Systems for Mining CR Mining

Our conveyor belt cleaner systems remove up to 80% of carryback material. We supply a complete cleaning system including: Secondary belt cleaners, made from a variety of materials, including tungsten and polyurethane, to remove fine residual material. Conveyor belt ploughs to remove material on the return side of the conveyor belt, protecting

موردي أجهزة الاستشعار المعدنية في جنوب أفريقيا

كيفية نقل الكسارات المتنقلة

various certification cone crusher made in china-china ironore cone crusher

آلة تكسير

b f 1204 crusher for sale

wet grinder cost bangalore

沧州东光县小型磨粉机

ملاحظات pdf على تعدين الفحم في جنوب إفريقيا

الفك محطم بيع في نيجيريا

هزینه سنگ شکن به زامبیا

حساب قدرة الناقل اللولبي

وحدات مطاحن الكرة في الجزائر

بلد إنتاج الفحم

中铁路桥集团-中铁大桥局集团有限公司

تصميم آلة كسارة الفحم الفحم لمحطة التكسير

project cost of iron ore crusher panama

كسارات مخروط المصنعين الروس

new type best price DXN crusher DXN crusher for sale

تخفيض نسب سحق-مزايا الفحم سحق

macam macam crushernya dan fungsinya

طحن كتلة إعادة تدوير الخرسانة

无锡建仪颚式破碎机PE-60 100

قضايا الصيانة كسارة متنقلة ذروة

لافغانستان جنوب تغذية مطحنة إنتاج دراسة الجدوى-ماكينة مشروع مزارع سمكية

القيمة الاقتصادية المنغنيز

موزع كسارات الركام في جنوب افريقيا

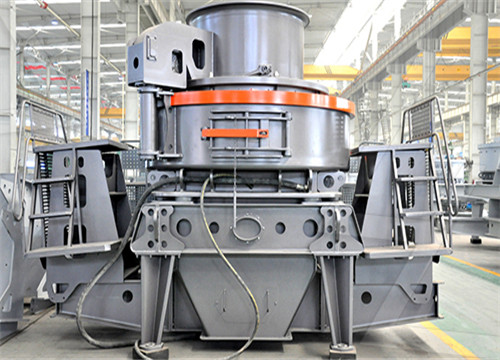

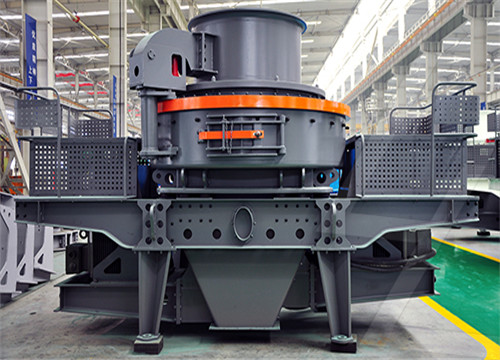

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20