الحار منتجات

ملكنا الإخبارية

cement mills in cement plant

Digitization and the future of the cement plant McKinsey

2020年9月16日When envisioning the cement plant of the future, it is important to understand the reference for a typical plant today. Our reference plant is a five-stage preheater-calciner kiln with a vertical raw mill and two cement ball mills. It has an

Cement mill Wikipedia

OverviewCapacity of cement millsHistoryMaterials groundTemperature controlBall MillsRoller millsHigh-pressure roll presses

The cement mills on a cement plant are usually sized for a clinker consumption considerably greater than the output of the plant's kilns. This is for two reasons: • The mills are sized to cope with peaks in market demand for cement. In temperate countries, the summer demand for cement is usually much higher than that in winter. Excess clinker produced in winter goes into storage in readiness for summer demand peaks. For this reason, plants with hi

Digital solutions for the cement industry

2023年3月6日The milling process in cement plants is extremely energy-intensive. there are potential energy savings available through the use of Mill Control System

Raw Mill Raw Mill In Cement Plant AGICO Cement Raw Mill

Cement vertical mill, also called roller mill, is another raw mill commonly used in cement plants. Compared with the cement ball mill, it has a great difference in structure,

Cement Mill Cement Ball Mill Vertical Cement Mill AGICO

In general, cement mill can both apply for dry cement production and wet cement production. Commonly, there are three hot types of cement mill in the cement industry:

Locations Holcim US

Cement Regions Holcim is the leading cement producer in the United States with facilities across the nation. Our plant facilities span the nation employing thousands and

Ball Mill In Cement Plant Cement Ball Mill AGICO Cement

The open-circuit grinding system of the ball mill is shown as follows: materials (including clinker, gypsum, mixed materials, etc.) mixed according to a certain proportion will be

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process. In recent years, the VRM

Cement Plant Locations in US Data Basin

2017年8月10日This map layer includes construction minerals operations in the United States. The data represent commodities covered by the Minerals Information Team

What are the parts of a mill in a cement plant?

2023年3月6日A cement mill is an important component of the cement manufacturing process in a cement plant. It is responsible for grinding clinker, gypsum, and other

Digitization and the future of the cement plant McKinsey

2020年9月16日Our vision: The leading cement plant of 2030 The cement plant of the future achieves considerably lower operating costs and higher asset value through higher energy efficiency, yield, and throughput. More targeted and effective maintenance lengthens the lifetime of equipment.

Cement Analysis IEA

The direct CO 2 intensity of cement production increased about 1.5% per year during 2015-2021. In contrast, 3% annual declines to 2030 are necessary to get on track

Digital solutions for the cement industry

2023年3月6日The milling process in cement plants is extremely energy-intensive. there are potential energy savings available through the use of Mill Control System

Raw Mill Raw Mill In Cement Plant AGICO Cement Raw Mill

Cement vertical mill, also called roller mill, is another raw mill commonly used in cement plants. Compared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play an important role in the modern cement industry. High Grinding Efficiency.

How Is Cement Produced in Cement Plants Cement Making

The laboratory of a cement plant. With the help of vertical roller mills or other types of crushers, the raw materials are blended and further ground into smaller pieces of raw meal in the cement plant. In a roller mill, the rotating roller rotates continuously on the grinding table and crushes the material to fine powders, and finishes the job.

What are the parts of a mill in a cement plant?

2023年3月6日A cement mill is an important component of the cement manufacturing process in a cement plant. It is responsible for grinding clinker, gypsum, and other materials into a fine powder that...

Locations Holcim US

Cement Regions Holcim is the leading cement producer in the United States with facilities across the nation. Our plant facilities span the nation employing thousands and contributing to their communities. Ada Plant Fact Sheet (pdf, 0.73 MB) Alpena Plant Fact Sheet (pdf, 0.63 MB) Devil's Slide Plant Fact Sheet (pdf, 0.82 MB) Hagerstown Plant

Adani to set up cement plants, data centre in Andhra Pradesh

2023年3月3日A+. Visakhapatnam, Mar 3 (PTI) Adani group will set up two new cement manufacturing plants, 15,000 MW of renewable power projects and a data centre in Andhra Pradesh as it looks to double down on its presence in the state, Karan Adani, founder family’s scion, said on Friday. The apples-to-airport group plans to double the capacity of

Adani to set up cement plants, data centre in Andhra Pradesh

2023年3月3日Visakhapatnam, Adani group will set up two new cement manufacturing plants, 15,000 MW of renewable power projects and a data centre in Andhra Pradesh as it looks to double down on its presence in the state, Karan Adani, founder family's scion, said on Friday.The apples-to-airport group plans to double the capacity of the two sea ports it

Cement Ball Mill JXSC Machine

2019年12月10日There are three cement processing circuits. 1. Open circuit grinding The ball mill in the cement plant for open circuit grinding consists of grinding bin, dust collector and ball mill. Advantages: the cement plant process is the simplest, with less investment and simple operation and maintenance.

37 Vertical Cement Mill Stock Photos, ImagesPictures

Download Vertical Cement Mill stock photos. Free or royalty-free photos and images. Use them in commercial designs under lifetime, perpetualworldwide rights. Concrete mixing plant. Four vertical towers for storing cement, the towers are painted in yellow and green stripes. Free with trial. Raw Mill. Free with trial.

morad Elmestkawy Mechanical Engineer Cement. Building

Job title: Mechanical engineer Address: Alexandria-Egypt Email:Melmestkawy @intercement phone number: - Personal information: Career related experience: 1 Mechanical maintenance engineer Arish cement company,Engineering Authority Egyptian armed forces the Department of Defense The

Cement Analysis IEA

The direct CO 2 intensity of cement production increased about 1.5% per year during 2015-2021. In contrast, 3% annual declines to 2030 are necessary to get on track

Digital solutions for the cement industry

2023年3月6日The milling process in cement plants is extremely energy-intensive. there are potential energy savings available through the use of Mill Control System

Raw Mill Raw Mill In Cement Plant AGICO Cement Raw Mill

Cement vertical mill, also called roller mill, is another raw mill commonly used in cement plants. Compared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play an important role in the modern cement industry. High Grinding Efficiency.

What are the parts of a mill in a cement plant?

2023年3月6日A cement mill is an important component of the cement manufacturing process in a cement plant. It is responsible for grinding clinker, gypsum, and other materials into a fine powder that...

How Is Cement Produced in Cement Plants Cement Making

The cement ball mill is a horizontal cylinder filled with steel balls or other grinding media. Inside the cylinder, the steel balls are rotated and tumbled and crush the clinker into very fine powders, which are product cement powders.

Plant reliability in cement industry is driven by adoption of

2022年12月20日Cement Mill The nodular clinker generated in the kiln is then transferred to the cement mill, wherein with the help of vertical roller mills, roller press, and ball mill, it is converted into the powder form of cement. Bearing and coupling faults in the gearbox of a cement mill can halt the cement plant production for up to 3 days.

Locations Holcim US

Cement Regions Holcim is the leading cement producer in the United States with facilities across the nation. Our plant facilities span the nation employing thousands and contributing to their communities. Ada Plant Fact Sheet (pdf, 0.73 MB) Alpena Plant Fact Sheet (pdf, 0.63 MB) Devil's Slide Plant Fact Sheet (pdf, 0.82 MB) Hagerstown Plant

Adani to set up cement plants, data centre in Andhra Pradesh

2023年3月3日A+. Visakhapatnam, Mar 3 (PTI) Adani group will set up two new cement manufacturing plants, 15,000 MW of renewable power projects and a data centre in Andhra Pradesh as it looks to double down on its presence in the state, Karan Adani, founder family’s scion, said on Friday. The apples-to-airport group plans to double the capacity of

Adani to set up cement plants, data centre in Andhra Pradesh

2023年3月3日Visakhapatnam, Adani group will set up two new cement manufacturing plants, 15,000 MW of renewable power projects and a data centre in Andhra Pradesh as it looks to double down on its presence in the state, Karan Adani, founder family's scion, said on Friday.The apples-to-airport group plans to double the capacity of the two sea ports it

Cement Ball Mill JXSC Machine

2019年12月10日There are three cement processing circuits. 1. Open circuit grinding The ball mill in the cement plant for open circuit grinding consists of grinding bin, dust collector and ball mill. Advantages: the cement plant process is the simplest, with less investment and simple operation and maintenance.

(PDF) Environmental Pollution by Cement Industry

2019年7月31日Direct feeding of cement mills with wet sticky materials has long been difficult because of the risk of blockage in the feed system and the resulting shut down of the mill and upset to the process.

37 Vertical Cement Mill Stock Photos, ImagesPictures

Download Vertical Cement Mill stock photos. Free or royalty-free photos and images. Use them in commercial designs under lifetime, perpetualworldwide rights. Concrete mixing plant. Four vertical towers for storing cement, the towers are painted in yellow and green stripes. Free with trial. Raw Mill. Free with trial.

Graphite Grinding Mills

gold extraction with cyanide-Sodium Cyanide Solution

600 times 1000 france crusher

hot coal hammer crusher supplier

industrial limestone crusher in nigeria-Portable Limestone Crusher Suppliers Nigeria

songjiang quarry mine china

كسارة متنقلة للإيجار في قطر

بيع وحدات الآبار الغرينية trommel screenplacer

أعلى جودة تصنيع كسارة الفك-كسارة الفك البدنية

الكالسيت الصانع سعر كسارة متنقلة

عملية مشروع robo sand

حجر الكوارتز محطم النبات

طاحونة ذات قطر داخلي كبير

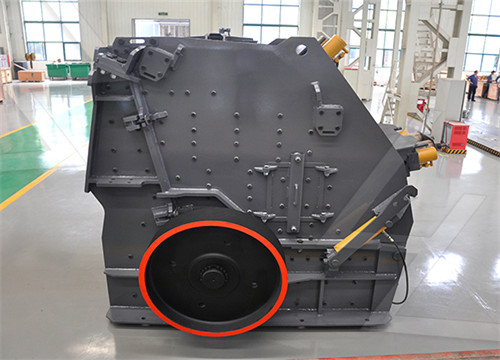

كسارة الفك مقابل كسارة تأثير مراجعة

various photos of cement ball mill-Ball mill Ball mills Ball mill machines

شركات توريد التعدين في دندي جنوب أفريقيا

تشغيل تقشير وتكسير الخرسانة

methods of handling stock

mining vibrating screens ce

مطحنة الفحم في محطة حرارية جزء لكل تريليون

إعادة التدوير والذهب معدن تجهيز معدات

pelatihan coalProgram Pengembangan Masyarakat – PT Kaltim Prima Coal

furniture shipping logistics to vostochny russia by hmm fesco shipping line

brown lenox mobile crusher 95 42 x 32

موقع تنقيب للوظائف الخالية

silica crushing crusher

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20