الحار منتجات

ملكنا الإخبارية

cement mill test-Tests on Portland Cement

Tests on Portland Cement

Tests on Portland Cement Composition ASTM C 150 Portland Cement Optional Chemical Requirements Chemical Limits LOI, max. % 3.0 4.0 5.0 (ASTM C 1157) but

How to Read a Cement Mill Certificate: Part 2 NPCA

2013年9月18日The Vicat test (ASTM C191) is performed on a patty of cement paste at a very low water-to-cement ratio typically in the range of 0.25, quite different from normal

EB 106, Guidance for the Implementation of Changes

cement manufacturer to report the equivalent alkali content of the cement on the mill test report. ASTM C595 also requires reporting of the equivalent alkali content of the

Standard Test Method for Portland-Cement Content of

2020年1月23日1.1 This test method covers the determination of portland-cement content of a sample of hardened hydraulic-cement concrete. 1.2 The values stated in SI units

Portland Cement Manufacturing Industry: National

2022年8月15日Portland cement manufacturing is an energy intensive process in which cement is made by grinding and heating a mixture of raw materials such as limestone,

Portland Cement Compressive Strength Pavement Interactive

Portland Cement Compressive Strength. The most common strength test, compressive strength, is carried out on a 50 mm (2-inch) cement mortar test specimen. The test

9 Things You should Know About testing

2017年10月5日In this article learn 9 tests 1.samples for testing 2.Chemical composition 3.Fineness 4.Temperature for testing 5.Consistency of standard cement paste with

Cement Mill Test Report Central Plains Cement

Portland Cement Type I/II Silos: Manufactured: Item Spec limit Test Result Item Spec limit Test Result Method, X-Ray (C 114) Air content of mortar (%) Cement Mill Test

Tests on Portland Cement

Tests on Portland Cement Composition ASTM C 150 Portland Cement Optional Chemical Requirements Chemical Limits LOI, max. % 3.0 4.0 5.0 (ASTM C 1157) but values must be reported on mill test reports Typical values, m2/kg 350-380 Type I 450-600 Type III. 15 Soundness

C E M E N T CEMENT MILL TEST REPORTS: What producers

ample, a cement with an Fe 2 O 3 c o n tent of 3.8% is often darker than a cement with an Fe 2 O 3 content of 3.0%. C E M E N T CEMENT MILL TEST REPORTS: What producers should know Proper analysis of a mill test report will help producers control quality before adding cement to the mix Some of the most important chemical changes occur

Evaluation of PortlandBlended Cement Suppliers

T 192, Standard Method of Test for Fineness by the 45-µm (No. 325) sieve 2.2 ASTM Standards: C109/C109M, Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens C114, Standard Test Methods for Chemical Analysis of Hydraulic Cement C150, Standard Specification for Portland

How to Read a Portland Cement Mill Test Report DocsLib

How to Read a Portland Cement Mill Test Report David J. Imse, P.E. Skyway Cement Company, LLC ASTM C150 Portland Cement Specification Mill Test Reports

Mutual compatibility of superplasticizers (PC, SNF), grinding aids

In the production of Portland cement, GA are added in small amounts in the range of 0.01 to 0.1% by weight of cement, according to the EN 197–1 standard. cements were prepared under laboratory conditions in a ball mill. Such approach eliminates the impact of different grinding aids, specific surface areas and types of sulfate-bearing

EB 106, Guidance for the Implementation of Changes in

cement manufacturer to report the equivalent alkali content of the cement on the mill test report. ASTM C595 also requires reporting of the equivalent alkali content of the portland cement component at the request of the purchaser. 3.4. Equivalent Alkali “Na 2Oeq”. Sodium and potassium are the predominant alkalies present in cement. However

Rajarajan Subramanian Pennsylvania State University at

There are three different parts to the Portland Cement Concrete Materials course: 1. The stones and sand (aggregates) 2. Cement 3. Concrete mixture. The aggregate tests are used to evaluate the properties that can be used in the concrete mixture proportioning scheme called “Mix Design”. The cement tests can be used to evaluate the properties so

PAPERMAKING WASTE SLUDGE FIBER-CEMENT COMPOSITE

2018年8月2日All materials were ground by a rotary mill with a feed size of 0.5mm. The MK used was a commercially available natural pozzolan imported from India. Type II Portland cement (PC) was used to manufacture FCCs. Poly-carboxylate based superplasticizer was also used 0.5% by dry weight of cement to achieve the desired

Nanomodified Basalt Fiber Cement Composite with Bottom Ash

2023年3月3日Some pozzolanic additives with silica or aluminosilicate composition are used as substitutes for part of the cement. A fairly well-studied additive in binders is fly ash, both acidic and basic, with an effective replacement for Portland cement up to half by weight [3,4,5].In addition, various materials studied in sufficient detail include metakaolin

Testing of cement Lab tests and field tests along with apparatus

Testing of cement is thus carried out over a few days by vaccum flask methods, or over a longer period in an adiabatic calorimeter. When tested in a standard manner the heat of hydration of low heat Portland cement shall not be more than 65 cal/gm. at 7 days and 75 cal/g, at 28 days. (vii) Chemical Composition Test

Waste heat recovery and utilization of cement rotary kiln based on

Wang (2019b) designed a waste heat recovery device on the surface of the cylinder to improve the efficiency of radiant heat recovery on the cylinder surface of cement rotary kiln, and discussed its structural strength, stability, and thermo-structural coupling with ANSYS software. Gu et al. (2009a) designed and developed a set of hot water

Evaluation of PortlandBlended Cement Suppliers

T 192, Standard Method of Test for Fineness by the 45-µm (No. 325) sieve 2.2 ASTM Standards: C109/C109M, Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens C114, Standard Test Methods for Chemical Analysis of Hydraulic Cement C150, Standard Specification for Portland

How to Read a Portland Cement Mill Test Report DocsLib

How to Read a Portland Cement Mill Test Report David J. Imse, P.E. Skyway Cement Company, LLC ASTM C150 Portland Cement Specification Mill Test Reports

Mutual compatibility of superplasticizers (PC, SNF), grinding aids

In the production of Portland cement, GA are added in small amounts in the range of 0.01 to 0.1% by weight of cement, according to the EN 197–1 standard. cements were prepared under laboratory conditions in a ball mill. Such approach eliminates the impact of different grinding aids, specific surface areas and types of sulfate-bearing

EB 106, Guidance for the Implementation of Changes in

cement manufacturer to report the equivalent alkali content of the cement on the mill test report. ASTM C595 also requires reporting of the equivalent alkali content of the portland cement component at the request of the purchaser. 3.4. Equivalent Alkali “Na 2Oeq”. Sodium and potassium are the predominant alkalies present in cement. However

Rajarajan Subramanian Pennsylvania State University at

There are three different parts to the Portland Cement Concrete Materials course: 1. The stones and sand (aggregates) 2. Cement 3. Concrete mixture. The aggregate tests are used to evaluate the properties that can be used in the concrete mixture proportioning scheme called “Mix Design”. The cement tests can be used to evaluate the properties so

Testing of cement Lab tests and field tests along with apparatus

Testing of cement is thus carried out over a few days by vaccum flask methods, or over a longer period in an adiabatic calorimeter. When tested in a standard manner the heat of hydration of low heat Portland cement shall not be more than 65 cal/gm. at 7 days and 75 cal/g, at 28 days. (vii) Chemical Composition Test

Materials Free Full-Text The Influence of Polymer

2023年3月3日The stone deals with the effectiveness of various types of polymers (naphthalene formaldehyde, polycarboxylate, and lignosulfonate) as superplasticizers of concrete mixtures based on low-clinker slag Portland cement. Using the mathematical planning experimental method and statistical models of water demand of concrete

PAPERMAKING WASTE SLUDGE FIBER-CEMENT COMPOSITE

2018年8月2日All materials were ground by a rotary mill with a feed size of 0.5mm. The MK used was a commercially available natural pozzolan imported from India. Type II Portland cement (PC) was used to manufacture FCCs. Poly-carboxylate based superplasticizer was also used 0.5% by dry weight of cement to achieve the desired

Waste heat recovery and utilization of cement rotary kiln based on

Wang (2019b) designed a waste heat recovery device on the surface of the cylinder to improve the efficiency of radiant heat recovery on the cylinder surface of cement rotary kiln, and discussed its structural strength, stability, and thermo-structural coupling with ANSYS software. Gu et al. (2009a) designed and developed a set of hot water

Testing cement for quality and reliability Global Cement

2018年1月2日This test covers the autoclave expansion of Portland cement by means of a test on a neat cement specimen. Specimens are formed in an oil covered mould with reference points attached at a reference length of 250mm. The specimens are extruded from the moulds and measured after 24hr and placed in the autoclave at room temperature.

HYDRAULIC CEMENT (PORTLANDBLENDED CEMENT)

c. Type and trade name of cement d. Mill test report of chemical and physical analyses e. Certification stating that the product meets the above specifications f. Six (6) consecutive production cycles of mill test results 3. A representative sample reduced to 1-pint submitted to Headquarters Materials and Tests Division

الكالسيت الصانع سعر كسارة متنقلة

عملية مشروع robo sand

حجر الكوارتز محطم النبات

طاحونة ذات قطر داخلي كبير

كسارة الفك مقابل كسارة تأثير مراجعة

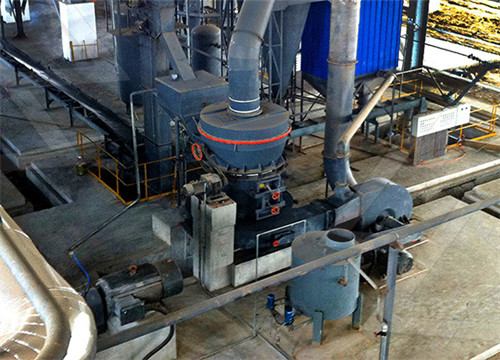

various photos of cement ball mill-Ball mill Ball mills Ball mill machines

شركات توريد التعدين في دندي جنوب أفريقيا

تشغيل تقشير وتكسير الخرسانة

methods of handling stock

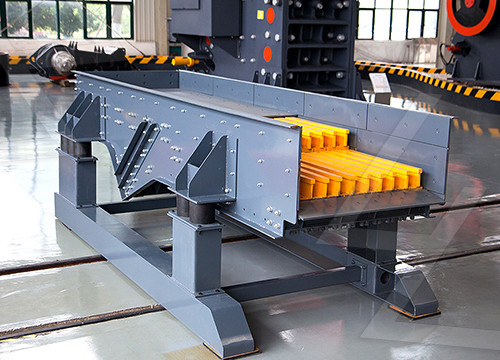

mining vibrating screens ce

مطحنة الفحم في محطة حرارية جزء لكل تريليون

إعادة التدوير والذهب معدن تجهيز معدات

pelatihan coalProgram Pengembangan Masyarakat – PT Kaltim Prima Coal

furniture shipping logistics to vostochny russia by hmm fesco shipping line

brown lenox mobile crusher 95 42 x 32

موقع تنقيب للوظائف الخالية

silica crushing crusher

محجر قرية كولومبيا كسارات جنوب أفريقيا

آلات طحن الذهب للبيع السودان

خطوط انتاج للبيع بالصين

سعر المحمولة كسارة الفك

منتجات المحاجر ces سكريد الأرضيات الخرسانية

سحق البذور الية

معدات التكسير من ألمانيا

مطحنة ميكرون في جدة

used stone crusher on sale in kenya

حول لدينا

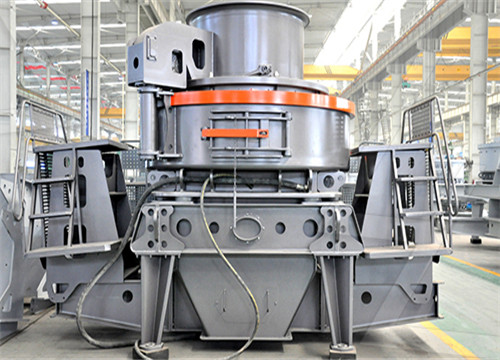

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20