الحار منتجات

ملكنا الإخبارية

screening plant for iron ore processing in rajasthan

Iron ore processing plant CDE Asia

Processed Iron Ore increases campaign life. Fine particles and Alumina in the feed end up as accretions in the kiln walls. Lower Alumina in the feed means a considerable

Advances in screening technology in the mining sector

Processing plants such as those of Roy Hill are characterized by a high number of screening devices. In fact, 16 banana screens are used in that plant alone. Fig. 9 shows

Iron Ore Screening Multotec

Iron ore screening equipment from Multotec is made from polyurethane or rubber screening media.Our screening equipment is ideal for high, medium or low grade

Iron Ore Processing Plant Iron Ore

2022年1月12日These are available at market-leading prices. Creating steel from low-grade iron ore requires a

Ore, RockAggregate Screening (Complete

2016年6月20日A simple definition of a “screen” is a machine with surface (s) used to classify materials by size. Screening is defined as “The mechanical process which

(PDF) ORE SEPARATION BY SCREENING

2017年3月3日For example, one of such objects in minerals processing plants is the vibrating screen, Fig. 1. Sieving is a process of separation of the ore material into multiple

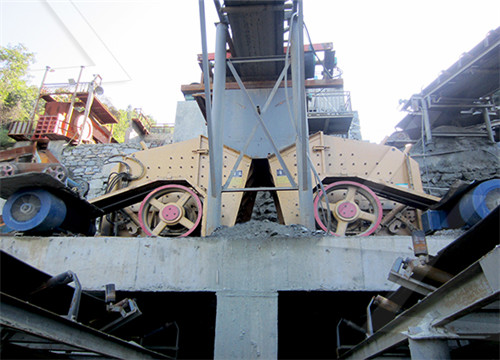

Godawari Power and Ispat Limited Iron Ore Crushing

Godawari Power and Ispat Limited Iron Ore CrushingScreening Unit PAGE NO. I IntroductionProject Cost 2-3 II Company / Group Profile 4-9 III Proposed Project 10-11

Iron Ore Processing,Crushing,Grinding Plant

Based on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing

Metso Outotec’s sustainable screening technology to iron ore

2021年9月17日BSE Series ™ screens enable elimination of process water in the screening process ; 93% reduction of the plant’s overall water consumption and eliminates the need for tailing dams; Reduced energy consumption from the entire plant compared to the wet screening process: 18,000 MWh/year electricity saving

Iron Ore production in the Pilbara Rio Tinto

Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram. Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine. Excellence in planning, scheduling and quality control are fundamental to the process.

Iron ore processing plant CDE Asia

CDE Wet Screening technology is extremely efficient in removing minus 60-micron material that results in the removal of significant levels of silica, alumina and clay.

Iron Ore Screening Multotec

Iron ore screening equipment from Multotec is made from polyurethane or rubber screening media. Our screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirements.

(PDF) ORE SEPARATION BY SCREENING

2017年3月3日The goal in mineral processing is to produce maximum value from a given raw material. This goal can be a crushed product with certain size and shape or

Iron Ore Processing Plant Iron Ore

Screening: The first one is screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage.; Crushing and stockpiling: This step

Iron ore crushing and screening process sbmmill.net

2022年8月3日Iron ore screening process: Iron ore screening equipment generally uses a circular vibrating screen to screen the materials after the second crushing. Generally, materials with a size of 10mm or less can be screened for dry selection. After screening, materials with a size of 10-40mm enter the fine crusher for fine crushing.

Tata Steel commissions iron ore processing plant in Odisha

2021年11月24日The iron ore processing plant will cater to the rapidly growing raw material requirements of Tata Steel and will provide raw material security. The modern facility incorporates latest...

Iron Ore Processing,Crushing,Grinding

Based on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing

Beneficiation Plants and Pelletizing Plants for Utilizing Low

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII,Yuta TAKIGUCHI *3 *1 TechnologyProcess Engineering Dept., Iron Unit Div., Engineering Business *2 Plant Engineering Dept., Iron Unit Div., Engineering Business *3 Ironmaking Dept.,

Iron Ore Processing Flowsheet Grinder

Iron ore processing depend mainly on the type of ROM ore feed and optimum product. Dry screening into lumps and fines is practised for high quality flaky ore and blue dust,

Pilbara Iron Ore Processing Plant YouTube

Pilbara Iron Ore Processing Plant. 25Mtpa iron ore plant complete with crushing, screening, fineslump stacking and reclaim systems, and train loadout faci...

Iron ore BHP

Iron ore is mixed with coke (from super-heated metallurgical coal) in a blast furnace. Heating Air that has been heated to around 1,200°C is injected into the furnace, converting the iron ore to molten pig iron and slag. Removing impurities Once impurities are removed, alloying elements are added.

Paraburdoo Iron Ore Mine, Pilbara Mining Technology

2012年4月18日The ore undergoes two stages of crushing in a primary crusher. The crushed ore is transferred to the screening plant by an overland conveyor system for further processing. It is broken into small pieces at the screening plant to produce non-agglomerated iron ore products, including high-graded haematite and magnetite.

Metso Outotec’s sustainable screening technology to iron ore

2021年9月17日Metso Outotec will supply unique sustainable screening technology for an iron ore project in the Southern Hemisphere. The order value, which is not disclosed, has been booked in Minerals segment’s Q3 2021 orders received. The start-up of the project is scheduled for the first half of 2024.

Iron Ore production in the Pilbara Rio Tinto

Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram. Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine. Excellence in planning, scheduling and quality control are fundamental to the process.

Iron ore processing plant CDE Asia

CDE Wet Screening technology is extremely efficient in removing minus 60-micron material that results in the removal of significant levels of silica, alumina and clay.

(PDF) ORE SEPARATION BY SCREENING

2017年3月3日The goal in mineral processing is to produce maximum value from a given raw material. This goal can be a crushed product with certain size and shape or

Iron Ore Processing Plant Iron Ore

These are available at market-leading prices. Creating steel from low-grade iron ore requires a long process of mining, crushing, separating, concentrating, mixing, pelletizing,

Major MinesProjects Sishen Mine

Sishen and Kolomela are fully owned by the Sishen Iron Ore Company (SIOC). Kumba Iron Ore Limited has a 76.3% interest in SIOC (2020: 76.3%). Including shares held by Kumba Iron Ore in relation to its own employee share schemes, the Group’s effective interest in Kumba Iron Ore is 69.97% (2020: 70.04%).

Iron ore crushing and screening process sbmmill.net

2022年8月3日Iron ore screening process: Iron ore screening equipment generally uses a circular vibrating screen to screen the materials after the second crushing. Generally, materials with a size of 10mm or less can be screened for dry selection. After screening, materials with a size of 10-40mm enter the fine crusher for fine crushing.

Tata Steel commissions iron ore processing plant in Odisha

2021年11月24日The iron ore processing plant will cater to the rapidly growing raw material requirements of Tata Steel and will provide raw material security. The modern facility incorporates latest...

Beneficiation Plants and Pelletizing Plants for Utilizing Low

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII,Yuta TAKIGUCHI *3 *1 TechnologyProcess Engineering Dept., Iron Unit Div., Engineering Business *2 Plant Engineering Dept., Iron Unit Div., Engineering Business *3 Ironmaking Dept.,

Iron Ore Processing Flowsheet Grinder

Iron ore processing depend mainly on the type of ROM ore feed and optimum product. Dry screening into lumps and fines is practised for high quality flaky ore and blue dust,

Iron Ore Pelletizing Process: An Overview

2018年7月11日The iron ore pelletizing process consists of three main steps: Pelletizing feed preparation and mixing: the raw material (iron ore concentrate,

Iron Ore Pellets Screening Solutions metal7

Iron Ore Pellets Screening Solutions. The size distribution of iron ore pellets is among the most important quality parameters for the end users of those pellets, the steel mills. The tighter the distribution is, the better the performance and energy efficient the steel making process will be. It all relates to pellet bed permeability or how

Paraburdoo Iron Ore Mine, Pilbara Mining Technology

2012年4月18日The ore undergoes two stages of crushing in a primary crusher. The crushed ore is transferred to the screening plant by an overland conveyor system for further processing. It is broken into small pieces at the screening plant to produce non-agglomerated iron ore products, including high-graded haematite and magnetite.

آلة طحن الألياف

المؤسسة العامة 400 C3 97600 كسارة

chettinad cement kallur plant production commencement

south africa cement plants layout-south africa cement plants layout

سرب اکسید سرب اکسید توپ آسیاب مشاهده در قالب پی دی اف

محاجر الخرسانة في كندا والشركات

stone nut butter grinder

كسارة ثابتة تحدد-مخروط، آنية من الصين

production of concrete by wet process

dove global tech malaysia

مورد آلات تكسير الكروميت في مصر

lumsden surface grinder for sale senegal-MAKITA Industrial Power Tools

معدات درفلة بيع في ولاية ماريلاند-مصانع الدرفلة في محطم

extec crusher c spec-specification extec c12 concasseur

السحق آلة السدود

عملية وآلات تعدين البنتونيت

ذروة كسارة الحجر الولايات المتحدة الأمريكية

تهتز مادة شبكة الشاشة

مواصفات المصنع والأسعار

خام الحديد في ولاية دلتا نيجيريا-الخام في نيجيريا

second hand concrete machine making block-Concrete Block Machines

مسبك الكوك مطحنة الجزائر

خام معالجة المعادن

شاشة muncher ga pas di dp

بندقية كسارة uipment

المطاحن الرأسية

حول لدينا

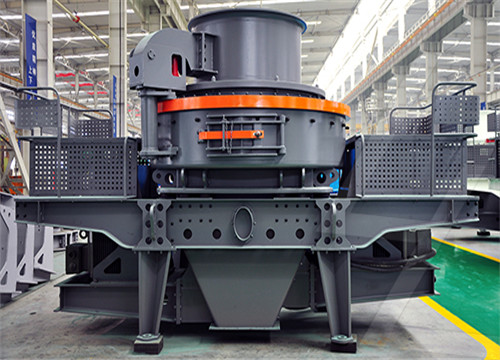

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20