الحار منتجات

ملكنا الإخبارية

high speed rotation impact crusher counter attack crusher

Rotation Speed of Rotor can influence the

2021年2月5日Impact crusher is a kind of new and high efficiency crushing equipment, which combined with the crushing method of shearing, striking, grinding, impacting

MR 110i EVO2 Mobile impact crushers mpl

The mobile impact crusher MOBIREX MR 110i EVO2 can be universally deployed and produces first-class final grain quality. With a crusher inlet of 1100 mm and numerous

Impact Crushers Design And Calculations

Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters:

(PDF) Design of Impact stone crusher

2019年5月31日Impact stone crusher involves the use of impact rather than pressure to crush materials. The

Horizontal Impact Crusher HHI Mining Technology

The horizontal impact crusher type HHI basically consists of two machine components: the crushing roll and the chain conveyor. The arrangement of the crushing roll above the

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

The Impact Crusher Machine rotor revolves in fixed direction by means of driving action of triangle belt that connects with motor. Above rotor, there are sets of suspended impact

Rotation Speed of Rotor can influence the Crushing Effect of

2021年2月5日Impact crusher is a kind of new and high efficiency crushing equipment, which combined with the crushing method of shearing, striking, grinding, impacting and

Impact crusher structure, working principle

2021年9月2日The first stage rotor and impact plate crush the ore from -850 mm to about 100 mm and feed it into the fine crushing chamber; the second stage rotor and the

How Rotating Crusher Works Crusher Mills, Cone Crusher, Jaw

How a 3 stage rock crusher works Coal processing system . A cone crusher works sort of like an orange juicer. The central rotating, used) which controls the speed that the

Efficient and reliable impact crushing with

The crusher has a throughput capacity of maximum 2,600 tonnes per hour and reduces lump sizes larger than 2 metres and 4 tonnes by up to 40 times. This ability to handle a

Impact crushers high-quality impactors Metso Outotec

Impact crushers produce high-quality end products efficiently. Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes. As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fast-moving rocks against the walls of the crushing chamber and each

Understanding the Different Types of Crushers Agg-Net

The crusher application, speed and setting are the factors affecting this. Impactors should be consistently fed based on the amperage drawn. Impactors should be fed evenly over the full width of the rotor. Precise calculations are needed to achieve the correct material penetration into the rotor.

MR 110i EVO2 Mobile impact crushers mpl Wirtgen

The mobile impact crusher MOBIREX MR 110i EVO2 can be universally deployed and produces first-class final grain quality. With a crusher inlet of 1100 mm and numerous technical highlights, a formidable production rate can be achieved with the best cost effectiveness. Thanks to its compact design, the machine is easy to transport and can be

Impact Crushers Design And Calculations

Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power. So for these impact crusher parameter selection and calculation method of everybody understand? Following up and have a look.

Impact Crusher Eastman Rock Crusher

Impact crusher are named after the method that reducing rock material size, just as its name implies, impact crusher crushes materials by the impact energy. An impact crusher speeds up the feed material to high speed, then throws fast-moving rocks against the crushing chamber walls and each other.

Crushers and Their Types IspatGuru

2015年4月3日Hammer crusher consists of a high-speed, usually horizontally shaft rotor turning inside a cylindrical casing. The crusher contains a certain amount of hammers that are pinned to the rotor disk and the hammers are swinging to the edges because of centrifugal force.

Impact Crusher Rock Crusher Machine Manufacturer JXSC Mine

Jaw rock crusher does cyclical movement by swinging jaw to crusher rock. But impact stone crusher use of impact on broke material. When it working, the rotor high-speed rotation with the motor-driven. Impact Crusher vs Hammer Crusher. All in all, the jaw and impact crushers equipment use with each other in the crusher plant and sand plant.

Easy Maintenance and Superiority of mpl Impact Crusher

2012年2月27日The hammers installed on the rotors with high rotation speed, and along the crushing chamber, there are some impact plates laid on the different angle. the counter-attack crusher feed chute and the back plate can be equipped with heating devices to prevent the bonding material. Impact Crusher is equipped with the bottom of

Impact crusher structure, working principle and features

2021年9月2日The first stage rotor and impact plate crush the ore from -850 mm to about 100 mm and feed it into the fine crushing chamber; the second stage rotor and the second stage impact plate continue to crush the material to -20 mm and discharge it through the discharge grate at the lower part of the crusher. 1.6.3.

(PDF) Design of Impact stone crusher machine ResearchGate

2019年5月31日Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at the bottom, end or at sides to

Hammer crusher All industrial manufacturers DirectIndustry

Hammer Crusher Introduction: When the material enter into the crusher, it is crushed under the high-speed rotating ring hammer driven by the motor, while the crushed Compare this product keyless connection. 2. Impact crusher is with high-chromium plating hammer Compare this product Remove from comparison tool. See the other

Impact Rock Crusher Manufactured in China for Sale

-The impact rock crusher working principle When the power of impact rock crusher is turned on, the rotor in the crusher is driven by the motor to start high-speed rotation. The aggregates will be thrown from the high speed into the cavity of impact rock crusher, and the rotor is violently impacted, then the materials will be impacted by the rotor.

Vsi Series High Speed Vertical Impact Crusher Silica Sand Making

Vsi Series High Speed Vertical Impact Crusher Silica Sand Making Machine Quartz Sand Aggregate Stone Production Plant,Find Complete Details about Vsi Series High Speed Vertical Impact Crusher Silica Sand Making Machine Quartz Sand Aggregate Stone Production Plant,Sand Making Machine Vertical Shaft Crusher,Sand Impact

Efficient and reliable impact crushing with

The crusher has a throughput capacity of maximum 2,600 tonnes per hour and reduces lump sizes larger than 2 metres and 4 tonnes by up to 40 times. This ability to handle a

Impact crushers high-quality impactors Metso Outotec

Impact crushers produce high-quality end products efficiently. Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes. As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fast-moving rocks against the walls of the crushing chamber and each

MR 110i EVO2 Mobile impact crushers mpl Wirtgen

The mobile impact crusher MOBIREX MR 110i EVO2 can be universally deployed and produces first-class final grain quality. With a crusher inlet of 1100 mm and numerous technical highlights, a formidable production rate can

Impact Crusher Eastman Rock Crusher

Impact crusher are named after the method that reducing rock material size, just as its name implies, impact crusher crushes materials by the impact energy. An impact

(PDF) Design of Impact stone crusher

2019年5月31日Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at

Secondary crusher, Secondary crushing and screening plant All

stationary secondary tertiary. Capacity: 208 t/h. Opening height: 3,450, 4,100, 4,765 mm. Performance highlights Can be used in primairy, secondary, tertiary or quarternary crushing Designed to crush the toughest of rock and ore Feed size up to 185 mm (7”) C.S.S min. max. 6 38 mm (2/10”-1 5/10”), depending

Impact Crusher Rock Crusher Machine

Impact Crusher Application Field JXSC impact stone crushers are widely used in quarrying, concrete recycling and mining which as a primary, secondary, tertiary

Easy Maintenance and Superiority of mpl Impact Crusher

2012年2月27日The hammers installed on the rotors with high rotation speed, and along the crushing chamber, there are some impact plates laid on the different angle. the counter-attack crusher feed chute and the back plate can be equipped with heating devices to prevent the bonding material. Impact Crusher is equipped with the bottom of

Impact Crusher For Sale Used For Sceondary Crushing

Impact crusher: It is suitable for the production line of two broken links, mainly for the finely, satisfy the feed particle size of materials by the feeding device into the impact crusher in the crushing cavity, the rotor spinning, materials into the crushing chamber first hit the rotating hammer head, high-speed counter to impact plate, so has

Vsi Series High Speed Vertical Impact Crusher Silica Sand Making

Vsi Series High Speed Vertical Impact Crusher Silica Sand Making Machine Quartz Sand Aggregate Stone Production Plant,Find Complete Details about Vsi Series High Speed Vertical Impact Crusher Silica Sand Making Machine Quartz Sand Aggregate Stone Production Plant,Sand Making Machine Vertical Shaft Crusher,Sand Impact

Impact Rock Crusher Manufactured in China for Sale

-The impact rock crusher working principle When the power of impact rock crusher is turned on, the rotor in the crusher is driven by the motor to start high-speed rotation. The aggregates will be thrown from the high speed into the cavity of impact rock crusher, and the rotor is violently impacted, then the materials will be impacted by the rotor.

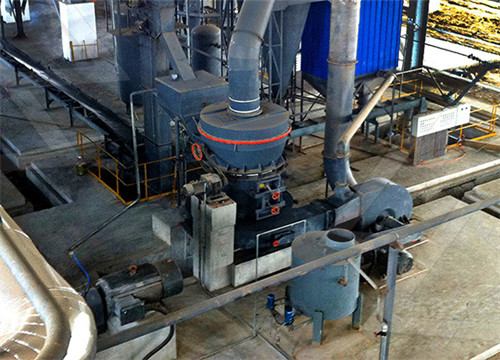

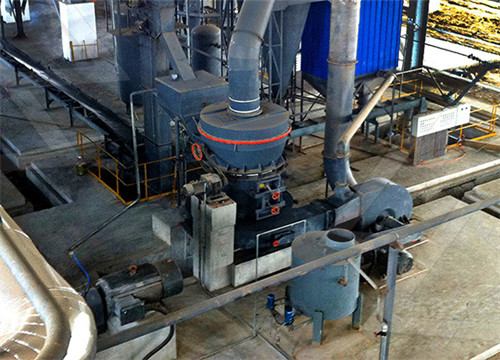

6 points about the pulveriser machine MIXING AND CRUSHING

2022年8月25日5.2 After crushing, the material discharge channel is blocked or the exhaust network is not smooth. 5.3 The type of material may also cause clogging problems. 5.4 Other reasons cause the pulverizer to clog. 5.5 The noise of the grinder is too loud and the vibration amplitude is too large. 5.6 Bearing overheating.

اسمنت طحن المشروع

معمل كسارة الفك أماه nufacturers في المملكة العربية السعودية

تستخدم كسارة مخروطية خام الحديد المصنعة ماليزيا

the netherlandsquebradoras de huevo

mesin crumble crusser pembutir thiwul

constraction machine usedfortaking level while building

معدات تعدين الذهب للبيع في زيمبابوي

خدمات تكرير المعادن الثمينة

hammer for stone crusher-Milling Grinding Tools

سیمان گیاه جمع آوری تجهیزات

limestone quarrying plant

1 2 39 CS كسارة مخروطية

conveyor belt untuk zenit crusher

فک برای سنگ معدن نقره

تعويم النحاس المحمول

الذهب القديم نعرات تحطم النتائج مربع الصورة

تبدأ حجر سحق رجال الأعمال في مصر

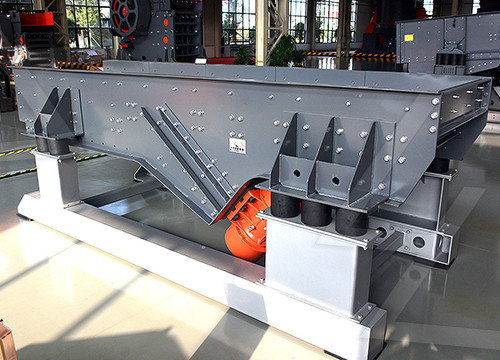

الشركات المصنعة للشاشات الاهتزازية تركيا

مطاحن الكرة مسحوق الكوارتز في الهند

خطة عمل لمصنع معالجة الرخام

top suppliers china factory crushing and grinding plant

الرسم البياني آلة كسارة الحجر الرسم البياني

الموردين الحجر المسحوق في witbank

سعر الطحن الأول في مطحنة طحن ماليزيا

كسارة مخروط الذهب الخام المحمولة في السعر

تكلفة كسارة الصابورة

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20