الحار منتجات

ملكنا الإخبارية

impact coal crusher working

作者: FUREIN

Coal Crusher Types- Impact& Double Roller

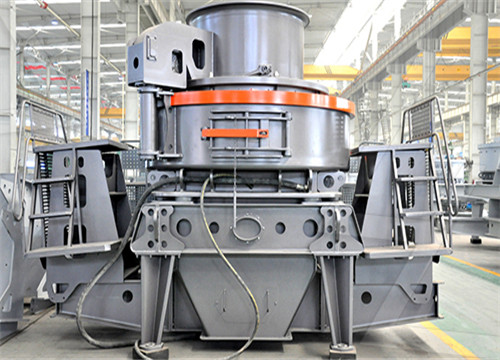

APF1214 impact Coal crusher Capacity: 130-200 (t/h) Model: APF1214 Rotor diameter (mm): Φ1200*1400 Feed opening size (mm): 450*1440 Max Feeding size (mm):

Impact Crusher Working Principle Mineral

2015年6月23日Impact crushing crushing is the reduction of materials by rubbing; primarily a grinding method.

Impact crusher structure, working principle and features

Impact Crusher StructureImpact Crusher Working PrincipleImpact Crusher Features

Although the impact crusher appeared late, the development is very fast, at present, it has been widely used in the medium and fine crushing industries of cement, construction materials, coal and chemical and mineral processing, etc, it also can be used as coarse crushing equipment for ore. The reason why the impact crusher is developing so rapidly...

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

In CHP crusher work on principle of combination of impact and attrition crushing. In this type of crushing first coal is break due to impact and further scrub between two hard

Construction Working and Maintenance of Crushers for

Construction Working and Maintenance of Crushers for Crushing Bulk

Ring Granulator Type Coal Crusher

2016年11月13日The crushing action is performed when material is dropped through the feed opening where it is struck, in mid air by the multiple rings which are being

Coal Impacter Working Animation Crusher Mills

this is the impact crusher detailed working procedures and other issues about the crusher. you can check the entire coal pulveriser ball mills animation bradford

Impact Crushers Primary McLanahan

Material enters an Impact Crushers' crushing chamber along a controlled feed angle. A spinning rotor assembly strikes the stone with a predetermined force sufficient to cause

Impact Crusher an overview ScienceDirect Topics

The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardness. Effect of process conditions on the production capacity of crushed materials is listed in Table 8.10. Table 8.10.

Impact crushers high-quality impactors Metso Outotec

Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes. As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fast-moving rocks against the walls of the crushing chamber and each other.

SafeEfficient Hydraulics Coal Crushing

2019年9月10日Impact crushers work by feeding material into a crushing chamber in which a rotor assembly spins. The rotor assembly has blowbars attached to it that strike and

ImpactCement Crusher Manufacturer Stedman Machine

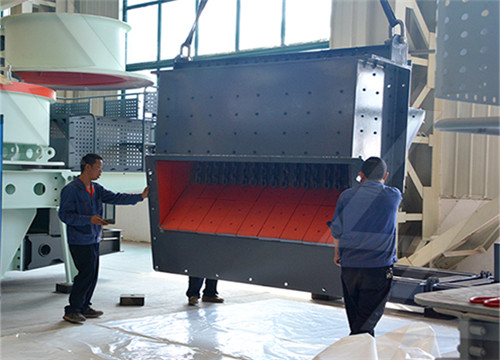

An impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a material. Impact crushers are designated as a primary, secondary, tertiary or quarternary rotor crusher depending on which processing stage the equipment is being utilized. Types of Impact Crushers: Horizontal shaft impactors (HSI) Cage mill pulverizers

Impact crusher structure, working

2021年9月2日1.1 Impact crushers can be divided into two types according to the number of rotors: single-rotor and double-rotor impact crushers. 1.2 The structure of the

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

In CHP crusher work on principle of combination of impact and attrition crushing. In this type of crushing first coal is break due to impact and further scrub between two hard surfaces to get desired coal size. Some crushers are work only on principle of impact crushing. Generally these crushers are used before final crushers. The output size

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

Coal Impacter Working Animation Crusher Mills

impact crusher animation crusher mining kefid machinery. this is the impact crusher detailed working procedures and other issues about the crusher. you can check the entire coal pulveriser ball mills animation .

What is the Difference Between Cone Crusher and Impact Crusher

2023年3月3日Cone crusher is mainly suitable for crushing ore and rock of medium hardness or above, such as granite, basalt, river stone, copper ore, diabase, etc. Impact crusher is mainly suitable for crushing stones with low hardness, such as limestone, river pebble, coal gangue, etc.

Coal Handling System Industry research report shares the latest

10 小时之Mar 07, 2023 (Prime PR Wire via Comtex) -- The Global Market Overview of "Coal Handling System Market"offers a unique insight into key trends shaping the...

Mobile Impact Crushers, QI Mobile Impact

Sandvik's mobile impact crushers are unparalleled on the market today. User-friendly by design, the operation of our mobile impact crushers is easy to master and makes

Unitoon × Truston Impact Crusher YouTube

About Press Copyright Contact us Creators Advertise Developers Terms Privacy PolicySafety How YouTube works Test new features Press Copyright Contact us Creators

Why use an impact crusher instead of other crushers?

2023年3月6日Higher reduction ratio: Impact crushers have a high reduction ratio of up to 20:1, which means they can reduce large, hard materials into smaller particles more efficiently than other crushers

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

Impact crushers involve the use of impact rather than pressure to crush materials. Here the material is held within a cage, with openings of the desired size at the bottom, end or at sides to allow crushed material to escape through them. This type of crusher is generally used with soft materials like coal, seeds or soft metallic ores.

Mobile Impact Crushers, QI Mobile Impact

Sandvik's mobile impact crushers are unparalleled on the market today. User-friendly by design, the operation of our mobile impact crushers is easy to master and makes

ImpactCement Crusher Manufacturer Stedman Machine

An impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a material. Impact crushers are designated as a primary, secondary, tertiary or quarternary rotor crusher depending on which processing stage the equipment is being utilized. Types of Impact Crushers: Horizontal shaft impactors (HSI) Cage mill pulverizers

Impact crusher structure, working

2021年9月2日Impact crusher working principle Impact crushers are machines and equipment that use impact energy to crush ore. In terms of the form of mechanical

Impact Crushers Secondary McLanahan

The NGS Impact Crusher is extremely easy to adjust, no heavy wrenches or cheater bars needed. All it takes is a simple pull on the hydraulic lever. Then, lift the shims from the cradle, secure them in the shim pack with a thumb-screw, and let off the hydraulic cylinder. Check the gap through the inspection door, and you're done.

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

Impact crushers involve the use of impact rather than pressure to crush materials. Here the material is held within a cage, with openings of the desired size at the bottom, end or at sides to allow crushed material to escape through them. This type of crusher is generally used with soft materials like coal, seeds or soft metallic ores.

Working Principle Of Impact Crusher

Mining jaw crusher; Impact crusher; Hammer crusher; Hydraulic impact crusher; Spring cone crusher; Hi-tech grinding mill Production Performance, Working Principle of Impact Crusher Dealing with the material with the side length 500mm, not more than 350MPa anti-pressure strength, Impact Crusher can be widely used in crushing the coarse

Unitoon × Truston Impact Crusher YouTube

2017年2月9日About Press Copyright Contact us Creators Advertise Developers Terms Privacy PolicySafety How YouTube works Test new features Press Copyright Contact us Creators

Coal Handling System Industry research report shares the latest

10 小时之Mar 07, 2023 (Prime PR Wire via Comtex) -- The Global Market Overview of "Coal Handling System Market"offers a unique insight into key trends shaping the...

What is the Difference Between Cone Crusher and Impact Crusher

2023年3月3日Cone crusher is mainly suitable for crushing ore and rock of medium hardness or above, such as granite, basalt, river stone, copper ore, diabase, etc. Impact crusher is mainly suitable for crushing stones with low hardness, such as limestone, river pebble, coal gangue, etc.

(PDF) A performance model for impact crushers ResearchGate

2002年10月1日It can be applied to both hammer and vertical-axis impact crushers with the help of the corresponding estimations for the impact energy per unit mass.Here we propose classification and...

Rub-Impact Fault Diagnosis of a Coal Crusher Machine by Using

2021年7月22日Then, the same method is applied to diagnose rub-impact fault of a coal crusher unit in a steel plant causing high vibration. The machine specification is also described in Sect. 3. Further, a comparison between the EPT and EMD has been carried out in that section. Finally, some concluding remarks and future scope of work are outlined

Roll Crushers McLanahan

How Roll Crushers Work Whether the application requires a single-stage or two-stage crusher, the forces necessary to perform the crushing remain the same: a combination of impact, shear and compression. The impact force occurs as the material enters the crusher and is impacted by the rotating roll.

انواع سنگ شکن و زغال سنگ آسیاب

سعر طاحونة الحديد الصناعية الصناعية

طحن في الموقع وكيشا إعادة التدوير-سحق آلة لإعادة تدوير الخرسانة

Tire Vibration SieveRotary Vibrating Sieve for Liquid Material Sieving

stone crusher for making sand powder crushers crusher-Stone Powder Crushing Machine

المطاحن الكرة الكوارتز

DXN gold mining equipment

كسارة حجارة جديدة الجزائر

gold coast mining company ghana ltd

تستخدم آلات سحق ملموسة سنغافورة

معدات الطحن للبيع كسارة للبيع-الدولوميت معدات الفحص للبيع

properties granite crusher dust

marble mines in udaipur kesariya ji

supplier for high gradient magnetic separator for nanoparticles

concrete crusher manufacturers

تستخدم كسارة الذهب سعر الجهاز

دستگاه سنگ شکن فلزی مغولستان

وسائط الطحن قابلة للتبديل

كسارة الفك جامع الغبار pdf

الحجر الجيري والرمل السعر في الهند-

super fine powder making machine

low noise hammer crusher in sales promotion

煤矿职工培训实验设备-得寶 670L 熱敏蠟紙 熱敏版紙

used underground mining trucks price

المحمولة كسارة مصنع غسل الذهب للبيع

rock crusher power attenuator

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20