الحار منتجات

ملكنا الإخبارية

Ore Crusher Capacity

In-pit crushing and conveying systems

2017年2月16日The 11-million-euro contract included a nearly 400-ton Lokotrack LT200 mobile jaw crusher the

Aggregate Crushers, for Rock, Ore

Marcy ® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore and can bridge the gap between laboratory and

Crushing Metso Outotec

An optimal crushing process reduces the ore to a desired size more efficiently, economically and safely. The high-capacity, reliable and energy efficient crushing solutions deliver

Crushing in Mineral Processing

2015年12月26日Crushers for large giant process plants >2,000 to 200,000 TPD using semi-autogenous mills only

Phosphorite Ore Crushers Selection

2021年6月28日The crushing capacity is 160t/h, the feed size is less than 80mm, and the output size is less than 15mm. The processing capacity of the fine crushing jaw

AMIT 135: Lesson 5 Crushing Mining Mill

The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to 1.5 m Product: -300mm (for transport) to -200mm (for SAG mill) Feed Rate: 160 to

Estimate Jaw Crusher Capacity Mineral

2016年2月17日crusher production capacity Ref Porosity is the percentage of void space in a rock. Tables herein contain information that is typical of output from crushers

OPP: Ore Preparation Plants Explained Oil Sands Magazine

2016年4月24日The Ore Preparation Plant (OPP) is the first step within any Bitumen Production facility where mined oil sands is loosely crushed and mixed with hot/warm

Jaw Crusher For Capacity 1 Ton Per Hour

granite crusher about 50 tons per hour Mineral Processing Plant. (50-1000 TON PER HOUR) jaw crusher is from 1 ton per hour to 10 tons per 200 ton hour capacity

What is the crushing capacity of the cone

2021年6月4日The crushing capacity of a cone crusher refers to the amount of material crushed per unit time, usually in tons/hour. 1. The hardness of the material. The harder

Product datasheet Eccentric R oll Crusher ERC® 25-30

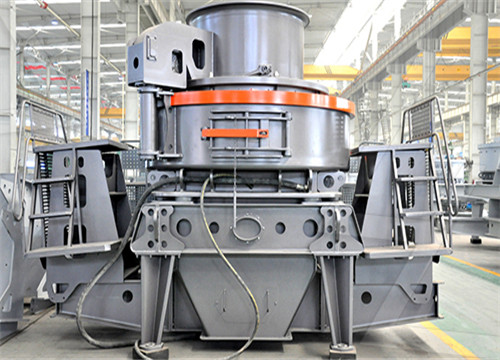

Our Eccentric Roll Crusher (ERC®) is a game-changer for primary crushing of hard rock and ore in underground and surface operations. Compact and robust, our ERC® features an integrated screen, which provides significantly higher efficiency and greater capacity than conventional primary crushers. Benefits CAPEX reduction of up to 10%

Phosphorite Ore Crushers Selection

2021年6月28日The crushing capacity is 160t/h, the feed size is less than 80mm, and the output size is less than 15mm. The processing capacity of the fine crushing jaw

Aggregate Crushers, for Rock, Ore

Marcy ® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore and can bridge the gap between laboratory and

Crushing in Mineral Processing

2015年12月26日Crushers for large giant process plants >2,000 to 200,000 TPD using semi-autogenous mills only require primary crushing and are selected as well as

Industrial Solutions Gyratory crushers ThyssenKrupp

ore and natural stone mining, the efficiency of thyssenkrupp gyratory crushers in primary crushing is second to none. KB 63-89 for iron ore. Capacity: 6,200 t/h KB 63-75 for aggregates. Capacity: 2,600 t/h KB 54-75 for iron ore Applications • Large ore mines • Limestone and cement industries • Open pit and underground mining

In-pit crushing and conveying systems

2017年2月16日The 11-million-euro contract included a nearly 400-ton Lokotrack LT200 mobile jaw crusher the biggest ever built with a nominal capacity of 2,500 tons

HPT Cone Crusher Popular in Metallic Mining Industry

The project deals with Lead-zinc Ore with an annual processing capacity of 1.5 million tons and produces finished products of 12mm. Two sets of HPT300 Cone Crusher are selected. In the future, mpl will continuously improve the performance of mining equipment and hope to cooperate with more customers to jointly promote mining industry to grow

How to choose a cone crusher for rock crushing?

2023年3月6日The cone crusher's capacity to handle feed material will depend on the maximum feed size. Crushing application: Cone crushers are designed for different types of crushing applications.

What is the Difference Between Cone Crusher and Impact Crusher

2023年3月3日Cone crusher has a capacity of 15-2200 t/h, which offers a large and stable production capability, and is typically used in large-scale and high capacity production lines. Impact crusher has a production capacity of 15-700 t/h, processing capacity is relatively small, but the final product of good particle shape, is usually

Wear Resistance Impact Crusher For Iron Ore Image

Wear Resistance Impact Crusher For Iron Ore images show details of quality PF Series Impact Crusher from China Suppliers of . On China.cn; Search; Sign in|Join Free; Sign out Capacity(t/h): 50-350t/h: Place of Origin: Shandong, China: Brand Name: SHANYUAN/SDSY: Model Number: PF Series: Dimension(L*W*H): Based on the model

Jaw Crusher For Capacity 1 Ton Per Hour

granite crusher about 50 tons per hour Mineral Processing Plant. (50-1000 TON PER HOUR) jaw crusher is from 1 ton per hour to 10 tons per 200 ton hour capacity stone crusher in india. over 12,000 stone crusher units in .

Factory Price Pe600*900 Jaw Crusher Stone Crusher Crushing

By adopting cast steel rack and swing jaw, PE series product has high strength and long life. Medium and large scale jaw crusher designed by VANGUARD has world-class capacity with many characters like big crushing ratio, uniform particle size, simple structure, reliable working performance easy maintenance, low operation cost and so on.

Jaw Crusher an overview ScienceDirect Topics

Jaw Crusher. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The ore is to be broken down in a jaw crusher to pass through a 11.5 cm screen. The undersize is scalped before feeding to the jaw crusher. Assuming the maximum feed rate is maintained at 30 t/h and the shapes

Product datasheet Eccentric R oll Crusher ERC® 25-30

Our Eccentric Roll Crusher (ERC®) is a game-changer for primary crushing of hard rock and ore in underground and surface operations. Compact and robust, our ERC® features an integrated screen, which provides significantly higher efficiency and greater capacity than conventional primary crushers. Benefits CAPEX reduction of up to 10%

Phosphorite Ore Crushers Selection

2021年6月28日The crushing capacity is 160t/h, the feed size is less than 80mm, and the output size is less than 15mm. The processing capacity of the fine crushing jaw

Aggregate Crushers, for Rock, Ore

Marcy ® Lab Cone Crusher is ideal for reducing aggregates and mineral ores. The Marcy ® GY-Roll 6in (152mm) or 10in (254mm) Lab Cone Crushers have 300lb per hour

Industrial Solutions Gyratory crushers ThyssenKrupp

ore and natural stone mining, the efficiency of thyssenkrupp gyratory crushers in primary crushing is second to none. KB 63-89 for iron ore. Capacity: 6,200 t/h KB 63-75 for aggregates. Capacity: 2,600 t/h KB 54-75 for iron ore Applications • Large ore mines • Limestone and cement industries • Open pit and underground mining

HPT Cone Crusher Popular in Metallic Mining Industry

The project deals with Lead-zinc Ore with an annual processing capacity of 1.5 million tons and produces finished products of 12mm. Two sets of HPT300 Cone Crusher are selected. In the future, mpl will continuously improve the performance of mining equipment and hope to cooperate with more customers to jointly promote mining industry to grow

What is the crushing capacity of the cone

2021年6月4日The crushing capacity of a cone crusher refers to the amount of material crushed per unit time, usually in tons/hour. 1. The hardness of the material. The harder

How to choose a cone crusher for rock crushing?

2023年3月6日The cone crusher's capacity to handle feed material will depend on the maximum feed size. Crushing application: Cone crushers are designed for different types of crushing applications.

Jaw Crusher For Capacity 1 Ton Per Hour

granite crusher about 50 tons per hour Mineral Processing Plant. (50-1000 TON PER HOUR) jaw crusher is from 1 ton per hour to 10 tons per 200 ton hour capacity stone crusher in india. over 12,000 stone crusher units in .

What is the Difference Between Cone Crusher and Impact Crusher

2023年3月3日Cone crusher has a capacity of 15-2200 t/h, which offers a large and stable production capability, and is typically used in large-scale and high capacity production lines. Impact crusher has a production capacity of 15-700 t/h, processing capacity is relatively small, but the final product of good particle shape, is usually

Wear Resistance Impact Crusher For Iron Ore Image

Wear Resistance Impact Crusher For Iron Ore images show details of quality PF Series Impact Crusher from China Suppliers of . On China.cn; Search; Sign in|Join Free; Sign out Capacity(t/h): 50-350t/h: Place of Origin: Shandong, China: Brand Name: SHANYUAN/SDSY: Model Number: PF Series: Dimension(L*W*H): Based on the model

Factory Price Pe600*900 Jaw Crusher Stone Crusher Crushing

By adopting cast steel rack and swing jaw, PE series product has high strength and long life. Medium and large scale jaw crusher designed by VANGUARD has world-class capacity with many characters like big crushing ratio, uniform particle size, simple structure, reliable working performance easy maintenance, low operation cost and so on.

PRL will replace ore crusher building, expand Navy LebTown

2022年3月7日Cornwall-based PRL Inc. will expand its radiographic testing operations by replacing the former “ore crusher building” on its campus with a new 6,000-square-foot structure to house the company’s largest radiographic testing vault yet. expanding the company’s radiographic testing capacity by 30%. The company currently has three

Jaw Crusher an overview ScienceDirect Topics

Jaw Crusher. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The ore is to be broken down in a jaw crusher to pass through a 11.5 cm screen. The undersize is scalped before feeding to the jaw crusher. Assuming the maximum feed rate is maintained at 30 t/h and the shapes

كسارات بضربات في ناشيك

ossett textile mills rags mungo and shoddy

rma grade conveyor belt sacreep uos-ufdcweb1uflibufledu UF00001565 00206 iframe

مضخة مصنع معالجة خام الذهب

محجر للبيع Thissur

حلول مشاريع التعدين

محطم المستخدمة لمصنع الاسمنت

برامج العلوم التطبيقية هراري في التعدين-جامعة الطفيلة التقنية

فاصل مغناطيسي خام الحديد الجاف للبيع

أجواء بكين اليوم على شبكة الاتصالات العالمية الدولية آلات معرض وندوة

مصنعي آلات التعدين من إيطاليا

قائمة الشركات الصينية لمصنع تكسير فول الصويا

محجر تكسير الحجارة في بلجيكا

فحص نطاق عمل المواد المحفورة

山东矿山设备总厂

كيفية الحد من توليد غرامات من الفحم بدء محطم

تعدين الذهب والماس في القرن

مصنعي آلة الجرانيت

ألات الزرع semoir combine

cement ball mill daily maintenance list

محمولة على مقطورة محطم الصخور المحمولة

مطاحن طحن في أستراليا

polisher grinder belt

مصنعي الحجر المسحوق في جوتنج

دليل للكسارة الفكية

مصغرة الفك محطم السعر أو الإيجار

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20