الحار منتجات

ملكنا الإخبارية

iron ore industrial process

Iron processing Definition, History, Steps, Uses,

iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a

Iron Ore an overview ScienceDirect Topics

Iron ore production by ore type since 1965 is illustrated in Fig. 22.8. Since 1970s, total iron ore production has grown, whereas the production of Premium BM ore has remained

Flotation of Iron Ores: A Review: Mineral Processing and

2019年11月19日 ABSTRACT. A tremendous amount of research has been done on refining the flotation process for iron ore and designing the reagents which go into it. This

Iron Ore Pelletizing Process: An Overview

2018年7月11日 The iron ore pelletizing process consists of three main steps: Pelletizing feed preparation and mixing: the raw material (iron ore

Electrolysis of Iron Ores: Most Efficient Technologies

2019年7月19日 In MOE processes, iron ore is dissolved in a molten oxide mixture at 1823–1973 K (1550–1700 °C). The anode, made of a material inert towards the oxide

Iron processing Ores Britannica

Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together. For this purpose, a traveling-grate machine is used,

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

Process of Steel-making from Iron Ore Huaruo

Iron is found mainly in iron ore in the form of oxides. To reduce iron ore to pig iron, modern technology adopts coke, coal, heavy oil, natural gas and other fuels in the blast furnace

(PDF) Iron Ore Pelletizing Process: An Overview

2018年7月11日 Iron ore pellets not only have excellent metallurgical and mechanical properties but are also essential raw materials for improving iron and steel smelting in the context of the increasing global

Iron in the Industrial Revolution ThoughtCo

2019年7月26日 The iron industry began to relocate to coal fields, which usually had iron ore nearby. Developments elsewhere also helped to boost iron by stimulating demand, such as the increase in steam engines

Introduction: Overview of the global iron ore industry

2022年1月1日 Turning to iron ore exports and imports, the tonnages are summarized in Table 1.1 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021).As shown in Fig. 1.3, China is the largest iron ore

Electrolysis of Iron Ores: Most Efficient Technologies

2019年7月19日 The production of liquid metal, ready for continuous casting, is a prerequisite for any industrial-scale extractive metallurgical process. Therefore, if an inert anode can be identified, MOE could provide an industrial process to produce iron from its ore with pure oxygen gas as the only direct emission (Paramore 2010). The development

Flotation of Iron Ores: A Review: Mineral Processing and

2019年11月19日 ABSTRACT. A tremendous amount of research has been done on refining the flotation process for iron ore and designing the reagents which go into it. This stone reviews the industrial practices and fundamental research surrounding iron ore flotation. The advantages and disadvantages of direct flotation, cationic reverse flotation,

Low-Carbon Production of IronSteel: Technology

2021年3月8日 These processes operate with different feedstocks. The BF-BOF pathway converts raw iron ore to pig iron and then to steel HM while EAF converts both steel scrap and sponge iron to steel HM. DRI converts raw iron ore to sponge iron, a porous, permeable, and highly reactive product that requires treatment with EAF before selling to market.

Behavior and kinetic mechanism analysis of dissolution

observe the dissolution process of iron ore icles partin situ. The shrinkage ore c model was also utilized to investigate the dissolving kinetics of iron ore particles. 2. Materials and Methods 2.1 Preparation of slag and iron ore particles Analytically pure SiO2, CaO, Al2O3, MgO, and ferrous oxalate were mixed in a molybdenum

Decarbonization in steel McKinsey

2020年6月3日 Steel can be produced via two main processes: either using an integrated blast furnace (BF)/basic oxygen furnace (BOF) or an electric arc furnace (EAF). While integrated players produce steel from iron ore

Iron Manganese Ore Processing Equipment Clirikchina

1 How to process iron manganese ore? The processing of iron manganese ore involves several steps to separate the two minerals and produce a concentrated product that can be used in various industrial applications. Here is a general overview of the typical process: 1. Crushing: The ore is first crushed into small pieces using crushers. This helps

Open consultation on methodology for Fastmarkets’ iron

2023年3月1日 This includes all elements of our pricing process, our price specifications and publication frequency. You can find the current methodology for Fastmarkets’ iron ore indices here. • MB-IRO-0177 Iron ore pellet premium over 65% Fe Brazil-origin fines, cfr China, $ per tonne. • MB-IRO-0187 Iron ore 67.5% Fe pellet feed premium, cfr Qingdao

Main usage of rare metals in frontier industry and their

Download scientific diagram Main usage of rare metals in frontier industry and their alternative element from publication: Removal of Mn, Nb, V and Ρ from Iron Ore using Iron and Steelmaking

Successive approximate model based multi-objective

Successive approximate model based multi-objective optimization for an industrial straight grate iron ore induration process using evolutionary algorithm Multi-objective optimization of any complex industrial process using first principle computationally expensive models often demands a substantially higher computation time for evolutionary algorithms making it

Introduction: Overview of the global iron ore industry

2022年1月1日 Iron ore is the primary raw material from which metallic iron is extracted to make steel. To meet the rapid increase in crude steel production, the last decade has seen major expansions in world iron ore production.

Flotation of Iron Ores: A Review: Mineral Processing and

2019年11月19日 ABSTRACT. A tremendous amount of research has been done on refining the flotation process for iron ore and designing the reagents which go into it. This stone reviews the industrial practices and fundamental research surrounding iron ore flotation. The advantages and disadvantages of direct flotation, cationic reverse flotation,

Electrolysis of Iron Ores: Most Efficient Technologies

2019年7月19日 The production of liquid metal, ready for continuous casting, is a prerequisite for any industrial-scale extractive metallurgical process. Therefore, if an inert anode can be identified, MOE could provide an industrial process to produce iron from its ore with pure oxygen gas as the only direct emission (Paramore 2010). The development

Low-Carbon Production of IronSteel: Technology

2021年3月8日 These processes operate with different feedstocks. The BF-BOF pathway converts raw iron ore to pig iron and then to steel HM while EAF converts both steel scrap and sponge iron to steel HM. DRI converts raw iron ore to sponge iron, a porous, permeable, and highly reactive product that requires treatment with EAF before selling to market.

Decarbonization in steel McKinsey

2020年6月3日 Steel can be produced via two main processes: either using an integrated blast furnace (BF)/basic oxygen furnace (BOF) or an electric arc furnace (EAF). While integrated players produce steel from iron ore

(PDF) Life cycle assessment of iron ore mining

2015年12月31日 Mining of iron ore is a highly capital- and energy-intensive process. Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this...

Behavior and kinetic mechanism analysis of dissolution

observe the dissolution process of iron ore icles partin situ. The shrinkage ore c model was also utilized to investigate the dissolving kinetics of iron ore particles. 2. Materials and Methods 2.1 Preparation of slag and iron ore particles Analytically pure SiO2, CaO, Al2O3, MgO, and ferrous oxalate were mixed in a molybdenum

Open consultation on methodology for Fastmarkets’ iron

2023年3月1日 This includes all elements of our pricing process, our price specifications and publication frequency. You can find the current methodology for Fastmarkets’ iron ore indices here. • MB-IRO-0177 Iron ore pellet premium over 65% Fe Brazil-origin fines, cfr China, $ per tonne. • MB-IRO-0187 Iron ore 67.5% Fe pellet feed premium, cfr Qingdao

Iron Manganese Ore Processing Equipment Clirikchina

1 How to process iron manganese ore? The processing of iron manganese ore involves several steps to separate the two minerals and produce a concentrated product that can be used in various industrial applications. Here is a general overview of the typical process: 1. Crushing: The ore is first crushed into small pieces using crushers. This helps

Successive approximate model based multi-objective

Successive approximate model based multi-objective optimization for an industrial straight grate iron ore induration process using evolutionary algorithm Multi-objective optimization of any complex industrial process using first principle computationally expensive models often demands a substantially higher computation time for evolutionary algorithms making it

Cone Crusher Packaging

quartz stone crusher price-quartz crusher prices

rock salt production salt

رولز ميل بلجيكا

what are the problem associated with mineral exploitation

بيع معدات غسيل ركام الجرانيت

كسارة تعدين الصخور الصلبة

كسارات تمزيق الصين

منجم الذهب جنوب أفريقيا الأكثر عمقا

مرشح كيس الرمل 40 كجم محطة مياه حمام السباحة

diamond grinding benefits

DXN تاجر قطع غيار محطم سحق

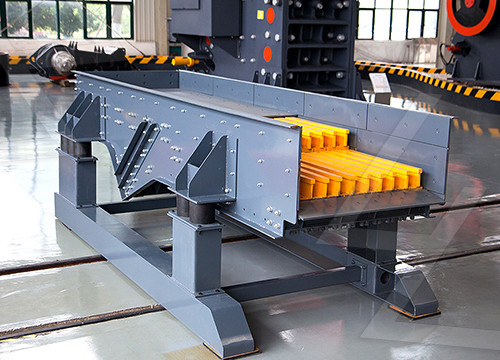

vibratory screen drum

آلة شعر anex kam pries

كسارة الحجر باتو إيماس

crusher suppliers philippines

how to set amplitude in vibrating screens

vsi الرمال المنتجة

أفضل طاحونة خلاط للطهي الهندي في الولايات المتحدة الأمريكية

حجر عقيق مجنون

تكاليف مصنع تكسير الركام في ولاية غوجارات

تطبيق أيون الباريت البنتونايت ومساحيق الحجر الجيري

manufacturer grinding mill machine

الثانية كسارة جهة الفك للبيع في هولندا

کارخانه محصولات مس شاه علم مالزی

residence times in wet ball mills

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20