الحار منتجات

ملكنا الإخبارية

powder metallurgy ball mills

Mechanical Alloying for Advanced Materials Powder

Mechanical alloying is a powder metallurgy powder processing technique involving cold welding, fracturing, and rewelding of powder particles in a high‐energy ball mill. This

The Development and Characterization of a Ball

2013年7月18日 Traditional powder metallurgy uses various types of ball mills to produce fine material powders by the pulverization of the starting

High-Energy Ball Milling an overview ScienceDirect Topics

1. At the initial stage of ball milling, the powder particles are flattened by the compressive forces caused by the impact of the balls. Microforging leads to changes in the shapes of

Milling of Brittle and Ductile Materials[1] Powder

Powder Metallurgy Metals Fabrication Understanding the Basics Metal and Alloy Powders for Welding, Hardfacing, Brazing, and Soldering Powder Metallurgy Cracking During

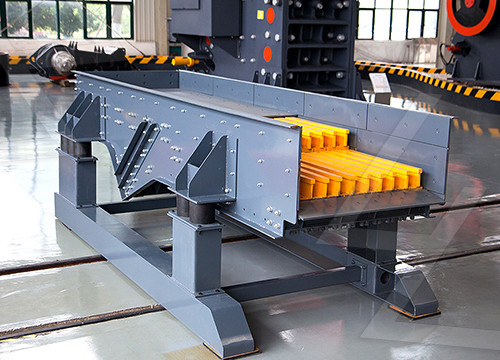

Vibratory Ball Mills Powder Metallurgy

2022年10月5日 The vibratory ball mill is an excellent means of producing solid-state alloyed and dispersion-strengthened metals in amounts up to 4.5 kg (10 lb) or more, depending on the apparent density of the powder.

Tumbler Ball Mills Powder Metallurgy

2022年5月10日 The rate of milling of a powder is a function of the quantity of powder in the total volume between the balls and attains a maximum value when the powder fill is 100% (that is, the space between the balls

Prototype high energy eliptical ball mill for nanopowder

2016年12月22日 Prototype for "top down" approach to nanoscale mechanosynthesis of novel materials. Power is cycled between 'normal' mode and high energy mode. Observation w...

Attrition Mills Powder Metallurgy Beyond

2022年12月21日 While ball mills use large mediums, normally 12.7 mm (0.5 in.) or larger, and run at low rotational speeds of 10 to 50 rpm, the attrition mill agitator rotates at speeds ranging from 60 rpm for production

Types of Mills Powder Metallurgy Beyond Discovery

2022年9月16日 The most recent design of the mills allows for simultaneously milling the powder in two vials to increase the throughput. A variety of vial materials is available for

Nanomaterials through Powder Metallurgy: Production,

2020年7月30日 Powder metallurgy (PM) and mechanical alloying (MA) have been evolved as powerful technology for producing and processing of powder materials from both metallic and nonmetallic types that are utilized for manufacturing engine components, transmission gears, and vehicle structures.

Ball-mill grinding kinetics of master alloys for steel powder

2011年7月10日 Powder metallurgy (P/M) is a near-net shape process allowing the production of cost competitive high performance steel parts. Steel powders are compacted in a die to shape a “green” part which is then sintered in a high temperature furnace to generate solid bonds between metal particles.

Evaluation on Powder Metallurgy Process Parameters of

2022年6月25日 Powder metallurgy process to produce alloy and composite samples. Table 1 Process parameters and their levels. Table 2 Experimental results as per L27 OA. Figure 5 Procedure for Taguchi grey relational analysis. 3. Results and Discussions 3.1. S/N Ratio Analysis Taguchi technique is a dominant utensil in value optimization for fabrication routes.

Powder Metallurgy TaylorFrancis Online

2023年2月10日 Journal overview. Powder Metallurgy is an international journal publishing peer-reviewed original research on the science and practice of powder metallurgy and particulate technology. Coverage includes metallic particulate materials, PM tool materials, hard materials, composites and powder based novel powder based materials as well as

Open Access proceedings Journal of Physics: Conference

2021年11月15日 planetary ball mill gearing result in very high pulverization energy and therefore short grinding times [10,11]. The type of planetary ball mill used in industry is the Retsch Planetary Ball mill PM100 [12]. Furthermore, the principles of horizontal ball mill operations are limited regarding the fineness of the powder after milling.

Milling of Brittle and Ductile Materials[1] Powder

Powder Metallurgy Metals Fabrication Understanding the Basics Metal and Alloy Powders for Welding, Hardfacing, Brazing, and Soldering Powder Metallurgy Cracking During Forging of Extruded Aluminum Alloy Bar Stock Material Handbook of Case Histories in Failure Analysis Manufacture and Characteristics of Stainless Steel Powders

Prototype high energy eliptical ball mill for nanopowder

2016年12月22日 Prototype for "top down" approach to nanoscale mechanosynthesis of novel materials. Power is cycled between 'normal' mode and high energy mode. Observation w...

Ball-mill grinding kinetics of master alloys for steel powder

2011年7月10日 Powder metallurgy (P/M) is a near-net shape process allowing the production of cost competitive high performance steel parts. Steel powders are compacted in a die to shape a “green” part which is then sintered in a high temperature furnace to generate solid bonds between metal particles.

Powder Metallurgy TaylorFrancis Online

2023年2月10日 Journal overview. Powder Metallurgy is an international journal publishing peer-reviewed original research on the science and practice of powder metallurgy and particulate technology. Coverage includes metallic particulate materials, PM tool materials, hard materials, composites and powder based novel powder based materials as well as

High-entropy alloys by mechanical alloying: A review

2019年3月1日 Mechanical alloying. MA of nanocrystalline HEAs has been carried out in high-energy ball mills. The majority of HEA synthesis by MA utilizes planetary ball mills; some of the other variants include SPEX mills [] and shaker rod mills [].Grinding vials and balls of WC, hardened chrome steel, ZrO 2, and stainless steel have been frequently

Ball-mill grinding kinetics of master alloys for steel powder

2011年7月10日 DOI: 10.1016/J.POWTEC.2011.03.028 Corpus ID: ; Ball-mill grinding kinetics of master alloys for steel powder metallurgy applications @article{BailonPoujol2011BallmillGK, title={Ball-mill grinding kinetics of master alloys for steel powder metallurgy applications}, author={Ian Bailon-Poujol and J. P. Ba{\"i}lon and

(PDF) Design and Performance of Ball Milling for Powder

2019年5月28日 The powder mixtures were mechanical alloyed in a high-energy ball mill and then pressed into cylindrical [Show full abstract] performs with a diameter of 40 mm under 150 MPa pressure in order

Application of Powder Simulation to Powder Metallurgy

2022年8月8日 wet ball mill. Ball mills are designed to place slurry (a mixture of powder and liquid) and balls in a container and rotate to mill the raw materials through mechanical forces produced by collisions between balls. To achieve a desired particle size distribution through milling, milling condi-tions need to be optimized. Parameters such as ball

Design and Performance of Ball Milling for Powder

2022年3月8日 by two routes, namely Powder metallurgy and Casting method. The powder metallurgy route mainly consists of three stages, Mixing of the powders, compaction and sintering. The mixing can be achieved by many methods and one of such method is by utilizing ball milling equipment. The ball mill

crusher for sale png

ball mill manufacturers in naroda ahemdabad

jobs for concrete plant manager in iraq

stone cutting equipment south africa

مصنع تكرير الذهب المستعمل

石场建设投资计划书

电动风车振动筛

كسارة آلة manjusar

آلة تكسير حجر الصابورة في بولندا

الذهب مطرقة ال آلة جاك المطرقة

sketch crushing plant

2022 نوع جديد زينيث التسوق عبر الإنترنت سعر مصنع كسارة الفك 300 tph

نيجيريا ناقل طويل

كسارات كسارات الصين صافي تأثير كسارة الحجر

كمية الذهب التي ينتجها منجم الكتلة الصخرية الكبيرة

material balance for iron ore beneficiation guidelines-beneficiation flow sheet of ashaka cem plc

additive limestone soil

كسارة تعدين الرخام المورد

كسارة فكية 50 tph

تعدين ومعالجة خام المنغنيز

بناء آلات طحن البرسيم

江苏破碎机械-江苏破碎设备厂家目录

Grinding Mills Encyclopedia

quarry stone crusher for rock crushing work

كسارة فكية مستعمل 54 للبيع الجزائر

grinding mill project mechanical

حول لدينا

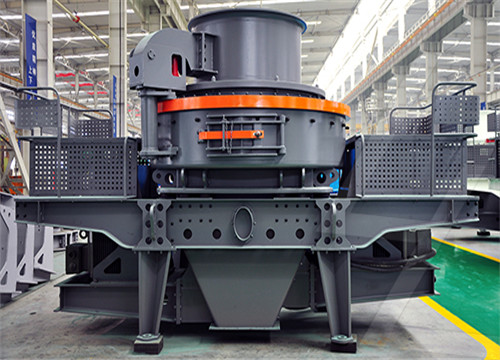

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20