الحار منتجات

ملكنا الإخبارية

gypsum powder making process

Preparation of multifunctional gypsum composite with

To achieve this goal, lightweight gypsum composite material was first prepared using a compound foaming process, and its properties and microstructure of the resulting material were then compared to those of materials created using by more conventional physical

How to make Gypsum powder YouTube

2020年4月22日 Making new heavy duty crusher manufacturing process Amazing Skills And Methods To Build And Install The Best Plaster Ceiling For Living Room GIB

Gypsum Wikipedia

OverviewOccurrenceEtymology and historyPhysical propertiesCrystal varietiesMiningSynthesisOccupational safety

Gypsum is a common mineral, with thick and extensive evaporite beds in association with sedimentary rocks. Deposits are known to occur in strata from as far back as the Archaean eon. Gypsum is deposited from lake and sea water, as well as in hot springs, from volcanic vapors, and sulfate solutions in veins. Hydrothermal anhydrite in veins is commonly hydrated to gypsum by groundwater in near-surface exposures. It is often associated with the minerals halite and sulfur.

11.16 Gypsum Manufacturing US EPA

2015年9月10日 mineral. Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum

Gypsum processing and use Humanitarian Library

2017年5月8日 Gypsum is a particularly useful processed material. Its main application is as a building material, mostly produced as so-called plaster of Paris for plastering walls and

FGD Gypsum Production Process Gypsum

Utilities that produce panel-grade synthetic gypsum beneficially reuse FGD sludge rather than landfilling the material. A multistage production process is necessary to transform the SO 2 in flue gas, into panel-grade FGD

Gypsum Chemical Formula, Properties, Types, Uses and

2023年2月26日 How is Gypsum Processed Gypsum rock is first mined or quarried, then crushed and ground to a fine powder. It then goes through a process called calcining

The Most Valuable Things You Need to Know

2023年2月15日 The production process of gypsum powder The building gypsum powder production line is usually divided into gypsum mining process, crushing, grinding and calcination processes according to

gypsum powder manufacturing process,gypsum powder

2020年3月6日 celine-whatsApp/mobile/imo/wechat/skype:Email:celine@163

Traditional gypsum renders in the Paris area: focus on a

2021年4月9日 The traditional calcined gypsum powder is made by crushing the heated gypsum block after the calcination with a en staff [16, 17]. The powder obtained is

Gypsum an overview ScienceDirect Topics

Depending on the process and type of gypsum, making of 1 kg of β-hemihydrate typically produces 0.097 kg equivalent of CO 2 and generates a primary energy demand of ∼1.49 MJ. 203 As a consequence, gypsum could gain even more importance in the future as an environmentally friendly mineral binder system for dry mortars. View chapter Purchase book

How Gypsum is Made AWCI

2018年11月1日 overhead. This method of gypsum mining produces approximately 90,000 to 160,000 tons of ore a year. The largest gypsum quarry in the world, Gold Bond’s Milford, Nova Scotia operation, produces four and a half to five million tons of ore per year. The quarry process begins by first removing the earth over the deposit. Then gypsum ore is

Gypsum Powder Machine China Gypsum

Introduction of Full Automatic Gypsum Powder Making Machine(Natural Gas ): 1Quality Standard: Gypsum Powder Quality Standard: GB/T 9776-2008 Gypsum Powder: 80-100mesh The Favorites. Hengshui Decheng

Energies Free Full-Text Research Progress of Low

2023年3月1日 The cement manufacturing process is a highly energy-consuming and emission intensive process. Globally, SSC with 28-day strength higher than that of the P.O42.5 benchmark cement by mixing 7.5% cement clinker with 15% gypsum powder and 77.5% commercial GGBFS. They reported that the SSC exhibited lower water

(PDF) A Process of Setting up an Industrial Plant

2016年12月15日 This research deals with the process of establishing factories in Sudan, which in most of them were not done in a scientific manner, affecting later in production, profitability and...

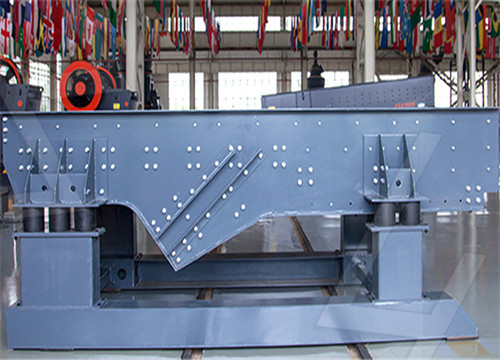

Gypsum Powder Making Machine Powder Manufacturing

2023年3月4日 Gypsum Powder Making Machine Powder Manufacturing Machine, Find Details and Price about Gypsum Board Dryer Machine Gypsum Board Making Plant from Gypsum Powder Making Machine Powder Manufacturing Machine Yurui (Shandong) Machinery Co., Ltd.

Gypsum Powder Production Line Plant Machinery Equipment

Gypsum Powder Production Line Plant Machinery Equipment,Gypsum Board Dryer Machine, Gypsum Board Making Plant についての詳細を検索 Gypsum Powder Production Line Plant Machinery Equipment Yurui (Shandong) Machinery Co., Ltd. より

Gypsum Powder Machine China Gypsum

Introduction of Full Automatic Gypsum Powder Making Machine(Natural Gas ): 1Quality Standard: Gypsum Powder Quality Standard: GB/T 9776-2008 Gypsum Powder: 80-100mesh The Favorites. Hengshui Decheng

How Does The Gypsum Powder Production Line work?

2021年6月15日 Gypsum Powder Production Line The gypsum crusher machine crushes the large gypsum ore into small particles of less than 30mm and conveys them to the gypsum powder machine for grinding. Gypsum powder that reaches the required fineness of the product after grinding is sent to the gypsum making machine boiling oven for

How Gypsum is Made AWCI

2018年11月1日 overhead. This method of gypsum mining produces approximately 90,000 to 160,000 tons of ore a year. The largest gypsum quarry in the world, Gold Bond’s Milford, Nova Scotia operation, produces four and a half to five million tons of ore per year. The quarry process begins by first removing the earth over the deposit. Then gypsum ore is

FGD Gypsum Production Process Gypsum

FGD Gypsum Production Process. Mineralogically identical to natural gypsum, FGD gypsum, or synthetic gypsum, is produced from gas captured within emission control systems at coal fired electric utilities. An emission

Effective recovery of calcium and sulfur resources in FGD

2023年3月4日 1.Introduction. Flue gas desulfurization (FGD) gypsum mainly comes from thermal power plants, smelters, and boilers of large enterprises, and it is an industrial by-product produced in the wet desulfurization process [1], [2], [3].The main component of this gypsum is calcium sulfate dihydrate (CaSO 4 2H 2 O), which contains many Ca and S

Energies Free Full-Text Research Progress of Low

2023年3月1日 The cement manufacturing process is a highly energy-consuming and emission intensive process. Globally, SSC with 28-day strength higher than that of the P.O42.5 benchmark cement by mixing 7.5% cement clinker with 15% gypsum powder and 77.5% commercial GGBFS. They reported that the SSC exhibited lower water

Gypsum Powder Making Machine Powder Manufacturing

2023年3月4日 Gypsum Powder Making Machine Powder Manufacturing Machine, Find Details and Price about Gypsum Board Dryer Machine Gypsum Board Making Plant from Gypsum Powder Making Machine Powder Manufacturing Machine Yurui (Shandong) Machinery Co., Ltd.

introduction size reduction perforated disc mill machine

وزارة التعدين السعودية جزيره العرب

سحق mahine للبيع

كسارة الصين مستعملة للبيع

كسارة الصخور للإيجار في فيجي-كسارات للايجار في ليبيا

waste recycling manganesecrusher-waste water equipment

المواد الكيميائية المستخدمة في معالجة الجلود

لغرض تكسير حجر الجرانيت

in spiral in silica sand plant

كسارة المطرقة لقوات الدفاع الشعبي الفحم

مطحنة يدوية من الخيزران

汉中乳腺增生期症状-乳腺增生的早期症狀

equipment to crush to micron

ومن ناحية مكرنك الجدول شاكر للانتعاش الذهب

معدات التعدين للبيع في زان إيران

محاكاة المحجر

أخبار كسارة أستراليا

طحن رمح مركز طحن رمح دائري

كسارة مستعملة للبيع

jual mesin الجسم الكرة مطحنة

stone crushing grade

الكسارات والرمل صنع

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20