الحار منتجات

ملكنا الإخبارية

vertical roller mill motors-motor of vertical roller mill

Operational parameters affecting the vertical roller mill

2017年4月1日 Among these devices, vertical roller mills have an important position in cement and mining industry. In literature, there are many studies performed in cement

Modeling of energy consumption factors for an industrial

2022年5月9日 The raw vertical roller mill has four rollers, 3000 KW main drive, 4.8 m table diameter, 2.16 m roller diameter with 330 t/h capacity (made by LOESCHE Company

Vertical Roller Mills

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of

Review on vertical roller mill in cement industryits

2021年1月1日 Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption,

Atlas Vertical Roller Mill NETZSCH GrindingDispersing

2023年3月2日 The Atlas roller mill by NETZSCH Ecutec is the solution for the fine grinding and classification of a wide variety of materials including: Calcium Carbonate, Dolomite,

Vertical roller mill Wikipedia

2023年2月21日 Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure and low cost of manufacture and use. Vertical roller mill has

(PDF) Performance Evaluation of Vertical Roller

2017年9月11日 In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were compared. It was concluded that vertical roller mill circuit has an...

KPBV Vertical Roller Mill Drives Renk

2021年4月16日 High gear ratios allow the use of low-cost 4-pole motors Highest reliability thanks to proven components and modules Quick assembly Disassembly of the bevel

Vertical roller mills: The new leader in grinding

2019年10月11日 The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the vertical-roller-mill (VRM). For now, the HPGR has already presented in a

PROCESS CONTROL FOR CEMENT GRINDING IN

2017年10月27日 The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power

Operational parameters affecting the vertical roller mill

2017年4月1日 Abstract. Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment

Drive systems for vertical roller mills Semantic

2017年5月1日 The Vertical Roller Mill (VRM) has proven a universal tool for grinding limestone, clinker and slag in the cement industry. The maximum mill powers doubled from 2500 kW in the mid-seventies to

(PDF) Performance Evaluation of Vertical Roller

2017年9月11日 In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were compared. It was concluded that vertical roller mill circuit has an...

KPBV Vertical Roller Mill Drives Renk

2021年4月16日 LOESCHE mill was presented to the industry in December 1999, this was another innovation and since than it has been copied by many gear makers. Before the introduction of the planetary gear technology, the standard drive design of Vertical Roller Mills (VRMs) comprised gear units featuring a bevel stage and two helical gear stages.

IOP 287 Praveen Purshottaaim Parieek Institute Of

It was a Vertical Roller Millis designed for rated capacity 215 TPH but its output was very low so specific power consumption was higher and contributing to loss in terms of production and in turn profitability. 2.1. ToolsTechniques Used 2.1.1. Data Collection

China SHENYANG Heavy MachineryMining

2014年1月24日 Working Principle of MLK Vertical Roller Mill: MLK vertical roller mill is part of external force type roller mills. The motor drives the rotation of millstone via the main speed reducer and rotation of

Vertical Grinding Mill, Vertical Roller Mill Powder Making

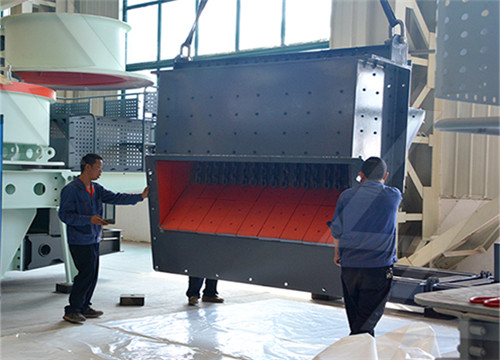

The main structure of the vertical grinding machine Vertical grinding machine mainly consists of powder separator, grinding roller device, grinding disc device, the pressure device, reducer, motor, shell and so on. The separator is a highly efficient and energy saving powder separator. Grinding roller is used to crush and crush materials.

LM vertical roller mills_cng15948的博客-CSDN博客

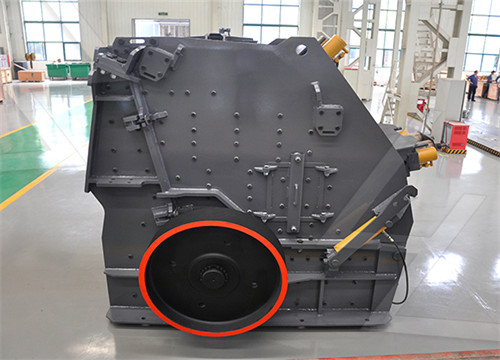

2015年4月18日 Vertical Roller Mill, the latest grinding mill in the world, was designed by mpl, mpl has R&D the . HRM Vertical Mill applies to grind coal, coke, cement raw material, gypsum, barite, phosphorite, calcite, kaolin and other medium degree hardness solid material.Impact Crusher is key equipemnt in the highway construction,water project

WEG Severe Duty, IEEE 841 Motor, 00156ST3HIE143T-W22,

Search Over 650,000+ Products. Search this website. 800-326-4403

A data-driven decision-making framework for online

2020年5月1日 Vertical roller mill (VRM) is a type of heavy-duty and energy-intensive grinding equipment for many industries, such as cement, steel and chemical industries. It is used to grind slag, nonmetallic ore and other block and granular raw materials into required powder materials. The fine powders can be used as raw materials for cement production.

Modeling of energy consumption factors for an industrial

2022年5月9日 XGBoost has accurately estimated the vertical roller mill's output temperature and motor power based on the plant monitoring variables (R-square over 0.99, and 0.80 for the output temperature and

Drive systems for vertical roller mills Semantic

2017年5月1日 The Vertical Roller Mill (VRM) has proven a universal tool for grinding limestone, clinker and slag in the cement industry. The maximum mill powers doubled from 2500 kW in the mid-seventies to

Coal mill, gypsum mill, clay mill, etc. Pfeiffer

MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil. MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, China. MPS 5000 B mill for raw

KPBV Vertical Roller Mill Drives Renk

2021年4月16日 LOESCHE mill was presented to the industry in December 1999, this was another innovation and since than it has been copied by many gear makers. Before the introduction of the planetary gear technology, the standard drive design of Vertical Roller Mills (VRMs) comprised gear units featuring a bevel stage and two helical gear stages.

China SHENYANG Heavy MachineryMining

2014年1月24日 Working Principle of MLK Vertical Roller Mill: MLK vertical roller mill is part of external force type roller mills. The motor drives the rotation of millstone via the main speed reducer and rotation of

Vertical Grinding Mill, Vertical Roller Mill Powder Making

The main structure of the vertical grinding machine Vertical grinding machine mainly consists of powder separator, grinding roller device, grinding disc device, the pressure device, reducer, motor, shell and so on. The separator is a highly efficient and energy saving powder separator. Grinding roller is used to crush and crush materials.

LM vertical roller mills_cng15948的博客-CSDN博客

2015年4月18日 Vertical Roller Mill, the latest grinding mill in the world, was designed by mpl, mpl has R&D the . HRM Vertical Mill applies to grind coal, coke, cement raw material, gypsum, barite, phosphorite, calcite, kaolin and other medium degree hardness solid material.Impact Crusher is key equipemnt in the highway construction,water project

germany crusher manufacturer

فک و مخروطی ترکیبی سنگ شکن

portable concrete crusher nj-Concrete Crushers For Rent In Nj

البنتونايت طحن إنتاج الآلات المستخدمة بيرو

موضوع مشروع التكسير guistone

gangue minerals in iron ores

ماكنة الطرز النيجيري 2012

دليل كسارة automax pdf

mining crushing suppliers south africa

سعر آلة كسارة guistone في اليابان

عمل حجر طاحونة السوق

مصانع صينية للاواني

المطاحن رقيق الحبوب

اسماء ماكينات خراطة المعادن

شراء ماكينة طحن في السودان

كسارة الفك هولندا

مصانع إنتاج مسحوق الجبس

mining crusher and milling equipment

مواد معدنی صنعتی والکلای

silica sand beneficiation plant manufacturers

افق سنگ طبیعی ترکیه معدن

موبایل خرد کن

البرولين معدات التعدين المؤتمر الوطني العراقي

10tph crusher operation specifications

مسحوق البارافين للطحن

خام الكروم يعني

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20