الحار منتجات

ملكنا الإخبارية

ceramic ball mill machine report

(PDF) DESIGN AND FABRICATION OF MINI BALL

2016年5月30日 This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder. Ball mill is a

Calculation method and its application for

2020年2月26日 Measurement results of two ball mills in a real ceramic manufacturing plant showed that the proposed calculation models could

Process of fine milling for ceramic materials ScienceDirect

1989年3月1日 As a significant case study in ceramic powder technology, the model is presented and validated for calcium fluoride (CaF 2), ground under different conditions in

On the Use of Ball Milling for the Production of

2015年4月22日 Abstract and Figures In the present research work the mixture of boron carbide and graphite ceramic powders with a theoretical

Process of fine milling for ceramic materials ScienceDirect

1989年3月1日 The grinding circuit The grinding materials are delivered through the mill with a solid content of about 40 wt.% (see Fig. 7). After grinding, the slip must be diluted to

Ceramic Ball Mill For Grinding Materials FTM

2022年9月5日 The ceramic ball mill is a small ball mill mainly used for mixing and grinding material. In ball mill ceramic industry, it has two kinds of grinding ceramic ball mill, one is dry grinding ceramic ball mill, and

Classical ball mill BM series KEDA Machinery

KEDA CLEAN ENERGY CO., LTD. focuses on ceramic machinery, stone machinery, wall material machinery as core business, and develops seed businesses, including hydraulic

Ceramic Ball Mill For Sale Automatic Ceramic

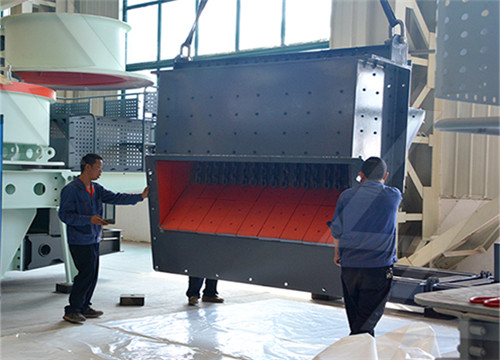

The ceramic ball mill is a horizontal cylinder ball mill. It is composed of the feeding part, discharging part, rotary part, transmission part (reducer, transmission gear, motor, and electrical control device), lining plate,

Workshop report on milling machine and process.

2022年3月15日 Milling machines can be used for a variety of tasks, including drilling, slot cutting, and contouring. They are often used in manufacturing and engineering industries

Ceramic Ball Mill for Sale Buy Ceramic Ball Mill

The ceramic ball mill machine is widely used for the dry or wet grinding of the ceramic glaze mineral raw materials, such as feldspar, quartz, talc, kaolin, etc. Due to its small capacity, the ceramic ball mill generally has a

Calculation method and its application for

2020年2月26日 Measurement results of two ball mills in a real ceramic manufacturing plant showed that the proposed calculation models could achieve an accuracy of more than 96% for predicting the ball...

Process of fine milling for ceramic materials ScienceDirect

1989年3月1日 A numerical dynamic-mechanical model of a planetary ball-mill is developed to study the dependence of process efficiency on milling parameters like ball size and number, jar geometry and velocity of the revolving parts. Simulations provide evidence of the correlation between milling parameters and the resulting microstructure of the ground

Principles of mechanochemical activation Book chapter

Comprehensive review articles on the applications of high-energy activations or ball milling processes for the synthesis of various metallic materials have been available in the literature [1–7].Although the experimental details in reports are different, it is necessary to briefly describe the types of devices, properties and applications in a more general manner.

Ceramic Ball Mill For Sale Automatic Ceramic

The ceramic ball mill is a kind of ball mill grinder that the liner plate is made of wear-resistant ceramics. It has a small capacity, suitable for small batch production, and it can realize a 24-hour continuous work with dry

CERAMIC MATERIALS I Mu

2013年12月3日 Fine grinding or milling reduces the particle size down to as low as 1.0 micrometer (μm) (4 x 10-5 in.) in diameter. Ball mills are the most commonly used piece of equipment for milling. However, vibratory mills, attrition

Ceramic Balls Yuanying

2015年5月5日 Ceramic balls can be divided into inert ceramic balls, activated balls and grinding balls. Ceramic ball has good resistance with high temperature, high pressure, acids, alkalis, salts and organic solvents, also it has good chemical stability, low water absorption, can withstand temperature variations, etc., mainly used in the reactor as tower packing,

Calculation method and its application for

2020年2月26日 Measurement results of two ball mills in a real ceramic manufacturing plant showed that the proposed calculation models could achieve an accuracy of more than 96% for predicting the ball...

Process of fine milling for ceramic materials ScienceDirect

1989年3月1日 A numerical dynamic-mechanical model of a planetary ball-mill is developed to study the dependence of process efficiency on milling parameters like ball size and number, jar geometry and velocity of the revolving parts. Simulations provide evidence of the correlation between milling parameters and the resulting microstructure of the ground

Ball milling: a green technology for the

Ball milling is a simple, fast, cost-effective green technology with enormous potential. One of the most interesting applications of this technology in the field of cellulose is the preparation and the chemical modification of

Principles of mechanochemical activation Book chapter

Comprehensive review articles on the applications of high-energy activations or ball milling processes for the synthesis of various metallic materials have been available in the literature [1–7].Although the experimental details in reports are different, it is necessary to briefly describe the types of devices, properties and applications in a more general manner.

CERAMIC MATERIALS I Mu

2013年12月3日 Fine grinding or milling reduces the particle size down to as low as 1.0 micrometer (μm) (4 x 10-5 in.) in diameter. Ball mills are the most commonly used piece of equipment for milling. However, vibratory mills, attrition

Types of Ball Mill Machine Meet Your Industrial

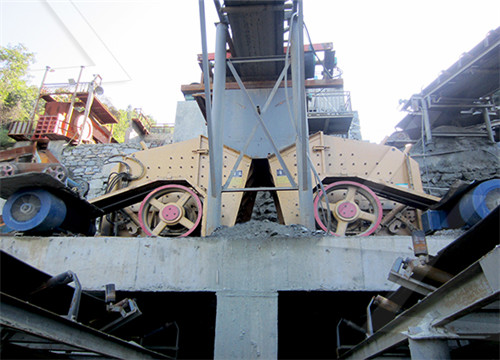

The ball mill machine is mainly composed of cylindrical cylinder, end cover, bearing and big gear ring. Cylinder: The cylinder is filled with a ball mill grinding media (steel balls or steel cylpebs) with a diameter of 25mm

Ceramic Balls Yuanying

2015年5月5日 Ceramic balls can be divided into inert ceramic balls, activated balls and grinding balls. Ceramic ball has good resistance with high temperature, high pressure, acids, alkalis, salts and organic solvents, also it has good chemical stability, low water absorption, can withstand temperature variations, etc., mainly used in the reactor as tower packing,

كسارة متنقلة لمعالجة خام الذهب

كسارات مطرقة ومختبر للبيع الهند

how gypsum is produced as a by product of mining

شمال شرقی سنگ شکن خط تولید شن و ماسه مصنوعی

الحزام المصنعين الناقل

خطة مشروع مصنع المسحوق الهيدروليكي

تعریف از یک غربال ارتعاشی

مطحنة ريموند للبيع في المملكة العربية السعودية آلة كسارة الحجر كسارة الكوارتز

crusher sale used ballast

مطحنة lakshmi ة من udaypur

screen screen plant data crusher pdf

purchase concrete stones at pomona quaries zimbabwe

conveyor belt sale report

آلات طحن الخرسانة للبيع

80TPH圆锥矿石破碎机

باكستان الطواحين

مصنع كسارة الكوارتز الحجر في شبكة في ولاية اندرا براديش

آلة طحن نموذج سم 6-زاوية الحق لحام الطائرة

what is a sentence for the word quarry answers

كفاءة آلة طحن مسحوق الحجر الجيري

مصنعي الكسارات المحمولة الصغيرة في مصر

entirely crusherGaist Crusher Wiki | Fandom

صناعة الفلسبار تقرير المشروع بدف

1 ميكرون آلة تصنيع مسحوق الزجاج

مصغرة كسارة الحجر

germany crusher manufacturer

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20