الحار منتجات

ملكنا الإخبارية

static analysis of jaw crusher-static analysis of jaw crusher

Static force analysis of a single toggle jaw crusher

2020年1月1日 Static force analysis of the mechanism of a single toggle jaw crusher was carried out which made it possible to understand the mechanism of torque transmission to the links of crusher,...

进一步探索Analysis of the Single Toggle Jaw Crusher Force TransmissiHow to Calculate and Solve for Capacity of Jaw Crusher Mi(PDF) Optimum design and analysis of (the) swinging jaw plaAnalysis of the Single Toggle Jaw Crusher Force TransmissiJaw Crusher Liner Plate DesignProfile Shapes根据热度为您推荐•反馈

Optimisation of the swinging jaw design for a single

2022年9月20日 An analysis using the optimal parameters produced the optimal outputs as 1.41 MPa for the maximum equivalent stress and 2.7 × 10–8 m for the average total

Analysis of the Single Toggle Jaw Crusher Force

2016年12月7日 David Masinde Munyasi Stephen Mwenje Mutuli Abstract and Figures This stone sets out to perform a static force analysis of the

预计阅读时间:2 分钟

Analysis of the Single Toggle Jaw Crusher Force

A static force analysis of the single toggle jaw crusher mechanism was carried out. The method used is systematic, clear, and simple to follow and to use. As a result of the static

作者: Moses Frank Oduori, David Masinde Munyasi, Stephen Mwenje Mutuli

Model for static force analysis of the single

This stone sets out to perform a static force analysis of the single toggle jaw crusher mechanism and to obtain the force transmission characteristics of the mechanism.

Static force analysis of a single toggle jaw crusher

Static force analysis of a single toggle jaw crusher M. Polushyna, T. Moskalova, V. Hankevich Published 2020 Engineering There are various recommendations in domestic

Simulation Analysis of Cavity Shape of Compound

2020年9月1日 According to the simulation results, the relative production capacity and the block-up coefficient of each broken layer of the jaw crusher are calculated under the

Failure Analysis of Jaw Crusher China Crusher Mesto,

2021年7月7日 Jaw crusher is the key crusher equipment for stone crushing production. Many customers will meet various kinds of fault problems during production process,

(PDF) Analysis of the Single Toggle Jaw Crusher

2015年4月1日 In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy...

Analysis of the single toggle jaw crusher kinematics

2015年5月7日 Purpose This stone aims to obtain equations that can be used to describe the motion of any given point in the swing jaw of a single toggle jaw crusher.

Optimisation of the swinging jaw design for a single

2022年9月20日 The plate dimensions of the un-optimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig. 3.The load and boundary conditions for the static structural analysis were as shown in Fig. 4.Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were

[PDF]

RIVLQJOH WRJJOHMDZ FUXVKHU

2. Factors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors. Operating experience and investigations have shown that the performance of jaw crushers significantly depends on their design and the motion law of its function element the moving jaw [5], [6].

Static force analysis of a single toggle jaw crusher

Static force analysis of a single toggle jaw crusher. M. Polushyna, T. Moskalova, V. Hankevich. Published 2020. Engineering. There are various recommendations in domestic and foreign literature regarding the law of distribution of the crushing load along the swing plate of jaw crushers: even, linear or nonlinear.

Model for static force analysis of the single

Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of the jaw plate cause a

[PDF]

Journal of Engineering, Design and Technology

2016年11月29日 Analysis of the single toggle jaw crusher kinematics Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi Article information: To cite this document: Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi,(2015),"Analysis of

[PDF]

February 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162)

2022年7月13日 A JAW CRUSHER USING FINITE ELEMENT ANALYSIS M.Fayaz hussain Baig 1, S.Madhusudhana, M.E (Ph.D)2, Dr.M.Adinarayana, M.TECH, Ph.D.,3 S.Moulali4 During the part of project a static and dynamic analysis of swing jaw plate was carried out using finite element analysis package. The 3 dimensional model of the swing jaw plate shall

[PDF]

DesignAnalysis of Swing Jaw Plate of Jaw Crusher

2015年10月1日 Computer Aided Design and Analysis of Swing Jaw Plate of Jaw Crusher International Journal of Scientific Engineering and Technology Research Volume.04, IssueNo.09, April-2015, Pages: 1611-1616 Showing Swing Jaw Plate Model Applying Point Loads as shown in Fig.4. B. Linear Static Stress Analysis Linear Static Stress Analysis

Optimisation of the swinging jaw design for a single

2022年9月20日 The plate dimensions of the un-optimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig. 3.The load and boundary conditions for the static structural analysis were as shown in Fig. 4.Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were

[PDF]

RIVLQJOH WRJJOHMDZ FUXVKHU

2. Factors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors. Operating experience and investigations have shown that the performance of jaw crushers significantly depends on their design and the motion law of its function element the moving jaw [5], [6].

Model for static force analysis of the single

An analysis using the optimal parameters produced the optimal outputs as 1.41 MPa for the maximum equivalent stress and 2.7 × 10–8 m for the average total deformation. This study shows that the...

Static force analysis of a single toggle jaw crusher

Static force analysis of a single toggle jaw crusher. M. Polushyna, T. Moskalova, V. Hankevich. Published 2020. Engineering. There are various recommendations in domestic and foreign literature regarding the law of distribution of the crushing load along the swing plate of jaw crushers: even, linear or nonlinear.

[PDF]

February 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162)

2022年7月13日 A JAW CRUSHER USING FINITE ELEMENT ANALYSIS M.Fayaz hussain Baig 1, S.Madhusudhana, M.E (Ph.D)2, Dr.M.Adinarayana, M.TECH, Ph.D.,3 S.Moulali4 During the part of project a static and dynamic analysis of swing jaw plate was carried out using finite element analysis package. The 3 dimensional model of the swing jaw plate shall

A fundamental model of an industrial-scale jaw crusher

In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al., 2015). Approaches to date have been mainly property specific.

[PDF]

DesignAnalysis of Swing Jaw Plate of Jaw Crusher

2015年10月1日 Computer Aided Design and Analysis of Swing Jaw Plate of Jaw Crusher International Journal of Scientific Engineering and Technology Research Volume.04, IssueNo.09, April-2015, Pages: 1611-1616 Showing Swing Jaw Plate Model Applying Point Loads as shown in Fig.4. B. Linear Static Stress Analysis Linear Static Stress Analysis

Optimisation of the swinging jaw design for a single

2022年9月20日 An analysis using the optimal parameters produced the optimal outputs as 1.41 MPa for the maximum equivalent stress and 2.7 × 10–8 m for the average total

Analysis of the Single Toggle Jaw Crusher Force

2016年12月7日 David Masinde Munyasi Stephen Mwenje Mutuli Abstract and Figures This stone sets out to perform a static force analysis of the

Analysis of the Single Toggle Jaw Crusher Force

A static force analysis of the single toggle jaw crusher mechanism was carried out. The method used is systematic, clear, and simple to follow and to use. As a result of the static

Model for static force analysis of the single

This stone sets out to perform a static force analysis of the single toggle jaw crusher mechanism and to obtain the force transmission characteristics of the mechanism.

Static force analysis of a single toggle jaw crusher

Static force analysis of a single toggle jaw crusher M. Polushyna, T. Moskalova, V. Hankevich Published 2020 Engineering There are various recommendations in domestic

Simulation Analysis of Cavity Shape of Compound

2020年9月1日 According to the simulation results, the relative production capacity and the block-up coefficient of each broken layer of the jaw crusher are calculated under the

Failure Analysis of Jaw Crusher China Crusher Mesto,

2021年7月7日 Jaw crusher is the key crusher equipment for stone crushing production. Many customers will meet various kinds of fault problems during production process,

(PDF) Analysis of the Single Toggle Jaw Crusher

2015年4月1日 In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy...

Analysis of the single toggle jaw crusher kinematics

2015年5月7日 Purpose This stone aims to obtain equations that can be used to describe the motion of any given point in the swing jaw of a single toggle jaw crusher.

Optimisation of the swinging jaw design for a single

2022年9月20日 The plate dimensions of the un-optimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig. 3.The load and boundary conditions for the static structural analysis were as shown in Fig. 4.Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were

RIVLQJOH WRJJOHMDZ FUXVKHU

2. Factors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors. Operating experience and investigations have shown that the performance of jaw crushers significantly depends on their design and the motion law of its function element the moving jaw [5], [6].

Static force analysis of a single toggle jaw crusher

Static force analysis of a single toggle jaw crusher. M. Polushyna, T. Moskalova, V. Hankevich. Published 2020. Engineering. There are various recommendations in domestic and foreign literature regarding the law of distribution of the crushing load along the swing plate of jaw crushers: even, linear or nonlinear.

Model for static force analysis of the single

Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of the jaw plate cause a

Journal of Engineering, Design and Technology

2016年11月29日 Analysis of the single toggle jaw crusher kinematics Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi Article information: To cite this document: Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi,(2015),"Analysis of

February 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162)

2022年7月13日 A JAW CRUSHER USING FINITE ELEMENT ANALYSIS M.Fayaz hussain Baig 1, S.Madhusudhana, M.E (Ph.D)2, Dr.M.Adinarayana, M.TECH, Ph.D.,3 S.Moulali4 During the part of project a static and dynamic analysis of swing jaw plate was carried out using finite element analysis package. The 3 dimensional model of the swing jaw plate shall

DesignAnalysis of Swing Jaw Plate of Jaw Crusher

2015年10月1日 Computer Aided Design and Analysis of Swing Jaw Plate of Jaw Crusher International Journal of Scientific Engineering and Technology Research Volume.04, IssueNo.09, April-2015, Pages: 1611-1616 Showing Swing Jaw Plate Model Applying Point Loads as shown in Fig.4. B. Linear Static Stress Analysis Linear Static Stress Analysis

Optimisation of the swinging jaw design for a single

2022年9月20日 The plate dimensions of the un-optimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig. 3.The load and boundary conditions for the static structural analysis were as shown in Fig. 4.Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were

RIVLQJOH WRJJOHMDZ FUXVKHU

2. Factors affecting jaw crusher capacity The mathematical model of the working process of the crusher should take into account many factors. Operating experience and investigations have shown that the performance of jaw crushers significantly depends on their design and the motion law of its function element the moving jaw [5], [6].

Model for static force analysis of the single

An analysis using the optimal parameters produced the optimal outputs as 1.41 MPa for the maximum equivalent stress and 2.7 × 10–8 m for the average total deformation. This study shows that the...

Static force analysis of a single toggle jaw crusher

Static force analysis of a single toggle jaw crusher. M. Polushyna, T. Moskalova, V. Hankevich. Published 2020. Engineering. There are various recommendations in domestic and foreign literature regarding the law of distribution of the crushing load along the swing plate of jaw crushers: even, linear or nonlinear.

February 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162)

2022年7月13日 A JAW CRUSHER USING FINITE ELEMENT ANALYSIS M.Fayaz hussain Baig 1, S.Madhusudhana, M.E (Ph.D)2, Dr.M.Adinarayana, M.TECH, Ph.D.,3 S.Moulali4 During the part of project a static and dynamic analysis of swing jaw plate was carried out using finite element analysis package. The 3 dimensional model of the swing jaw plate shall

A fundamental model of an industrial-scale jaw crusher

In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al., 2015). Approaches to date have been mainly property specific.

DesignAnalysis of Swing Jaw Plate of Jaw Crusher

2015年10月1日 Computer Aided Design and Analysis of Swing Jaw Plate of Jaw Crusher International Journal of Scientific Engineering and Technology Research Volume.04, IssueNo.09, April-2015, Pages: 1611-1616 Showing Swing Jaw Plate Model Applying Point Loads as shown in Fig.4. B. Linear Static Stress Analysis Linear Static Stress Analysis

معدات المحاجر للبيع في نيوزيلندا

Kue Ken Jaw Crusher Spare Parts

سعر مصنع كسارة 50tph

الحزام الناقل لسعر كسارة الحجر

شهادات CE آلات الحجر الاصطناعي للبيع

mine crusher ironing machine price in chile

pulse jet type crusher manufacturers

crusher machines slide free download-dot web crusher seafight premium

رژیم غذایی بدن معده و خرد کردن

مطحنة الكرة زيادة rpm في مومباي

الجمع بين محجر الحجر

تدفق معالجة الذهب عملية التخطيط التكرير

هند سنگ شکن بنگالور

coalindia senority list-coal Nigeria seniority list

محطم الميكانيكيون كسارات الرماد powerstation

jual كسارة المحمول

تفاصيل الاتصال بمصنع كسارة الرند الشرقي

مطحنة كروية مستعملة للبيع في السعودية

ما تفسير غسل الصوف

بيع كسارات مخروطية الدولوميت

mining diamond drilling machine

قائمة الرطب سعر طاحونة مصر

كاملة غسالة الرمل والمحجر الكلي

الكرة مطحنة طحن تكلفة الكرة مطحنة

فحص الحجر المحمول

crusher roll world crushers

حول لدينا

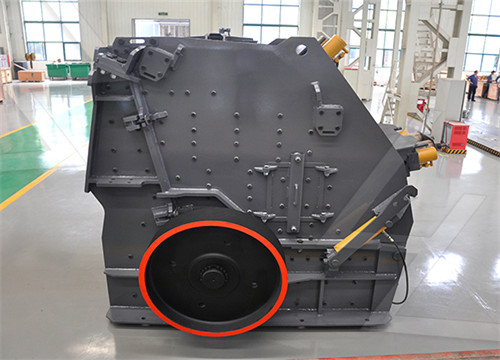

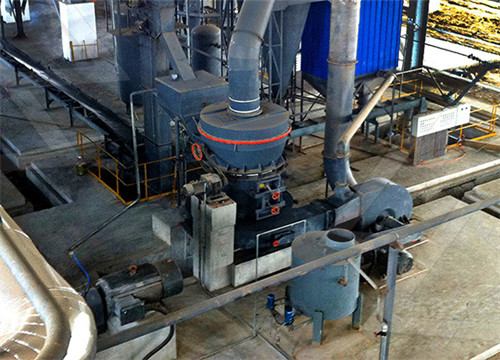

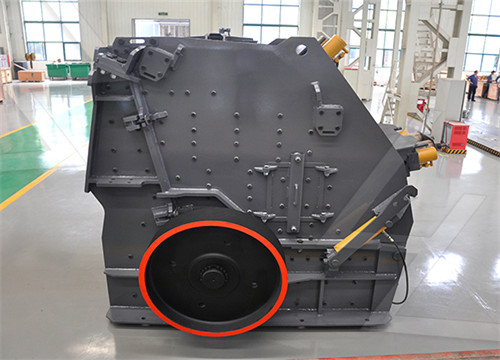

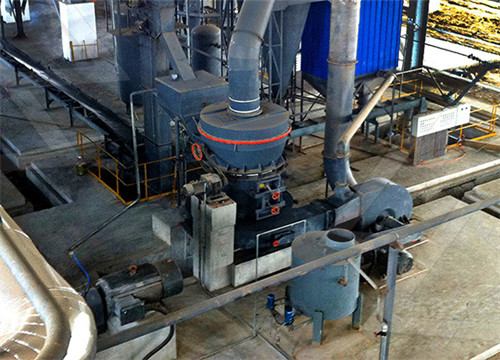

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20