الحار منتجات

ملكنا الإخبارية

testablishing a small flotation cell plant

DESIGN OF FLOTATION CIRCUITS WITH

2021年2月24日 Boliden Mineral AB As the size of conventional flotation cells increases, the proportional increase in surface area is smaller than that of the volume increase. This causes higher expected...

Troubleshooting and Diagnostic of Industrial Flotation

2009年1月1日 Also, typical boundaries for superficial gas rate (1-2 cm/s) and mean bubble size (1-2mm) have been identified for stable flotation operation from different plant

Recovery vs. mass pull: The link to air recovery

2010年10月1日 In a mechanical flotation cell, macro hydrodynamics is responsible for solids suspension and aggregates transport, and micro-turbulence plays an important

en/testablishing a small flotation cell plant.md at main

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Flotation Circuit Optimization Using Modelling and

2021年3月22日 The detailed modelling and simulation of flotation circuits can effectively reduce risks associated with the process scale—up and plant modifications, improve the

Small Flotation Machines 911Metallurgist

2023年3月4日 These ALL STAINLESS STEEL flotation machines are used to form banks of 2 cells. The can be arranged in series to accommodate small plants of up to 1 TPH (24 Ton/day). View the description below for

Flotation Plant Optimization Metallurgist

2019年7月21日 During the sampling period,the flotation procedure was not changed; therefore no information was obtained on many of the flotation variables. The results can be used, however, to indicate how retention

Pilot Plant: GrindingFlotation Cells 10 KPH YouTube

2020年12月1日 A beautiful and complete pilot plant for small scale study. Includes a 10 Kilos/hour (22 lbs/hr) rod or ball mill with spiral classifier + rougher, scavenger...

Establishing the Relationship between Grind Size and

Flotation recovery is strongly affected by the liberation of the mineral particles in the flotation feed. Thus, to optimise flotation grade and recovery it is usually best to grind to a fine size.

Combined Column and Mechanical Flotation Cell Process

2021年12月3日 The process consisted of one rougher stage (FCSMC 200 mm × 4000 mm), one cleaner stage (FCSMC 150 mm × 4000 mm), and one scavenger stage (mechanical flotation cell). Two tests, which lasted at least 8 h each, were performed in a closed circuit and an open circuit. The rougher column and the cleaner column were

Machine vision based monitoring of an industrial flotation

2014年12月10日 1. Introduction. Flotation is a physico-chemical separation process that utilizes the difference in surface properties of the valuable minerals and the unwanted gangue minerals (Wills and Napier-Munn, 2006).In a flotation cell, already conditioned fine particles with reagents (i.e. collectors and frothers) are subjected to air bubbles and the

New approach for flotation process modelling and

2020年9月1日 The aim of this work consisted of developing a flotation model based on industrial data from modern and large mechanical flotation cells (up to 300 m 3).Using industrial data from different flotation plants a general model was develop considering the metallurgical performance, residence time distribution, and operational and

Flotation of PGM-containing minerals: Plant-wide

2013年12月1日 This section briefly presents the methodology followed when developing a flotation circuit model which is then fitted to available plant data. The methodology consisted of the following steps: 1. Review collected data and compile a model training data set. 2. Configure circuit flow sheet in the Cycad process modelling package. 3.

Froth recovery measurements in an industrial flotation cell

2013年11月1日 Flotation is a complex separation process that exploits the physicochemical surface properties of mineral particles to separate the valuable minerals from the waste rock. It is widely used for beneficiation of ores such as metallic sulphides, feldspar, mica, salt minerals and cassiterite along with industrial minerals.

SELECTION OF MECHANICAL FLOTATION EQUIPMENT

2021年6月24日 flotation cell rotor. Traditionally flotation plant design blower selection and control has been based on using an oversized positive displacement blower, or an industrial fan, with any excess air discharged to atmosphere. While easy to select and design, this type of circuit contains inefficiencies especially when it comes to energy consumption.

Recovery of fine gold loss to tailings using advanced

2022年6月30日 This study evaluates the fine gold losses in the existing circuit using the size by size analysis and looking at the mineralogy by applying microscopic measurements to address whether the losses are related to association issues

Design and construction of a continuous pilot flotation

2022年11月7日 1.Introduction. Flotation is largely dependent on differences in surface wettability of valuable species and gangue in an aqueous slurry or pulp (Hanumanth and Williams, 1988).The surfaces of valuable particles are either inherently hydrophobic by natural surfactants or selectively rendered to be hydrophobic by an additive—synthetic

Minerals Free Full-Text Investigations on Single Minerals

Notice. You are accessing a machine-readable page. In order to be human-readable, please install an RSS reader.

testablishing a small flotation cell plant 123chauffage.fr

The effect of underground mine water on performance of the . Hardinge conical ball mills 6 of the small mills have since been replaced by two 14 ft x 18 ft Vecor mills The flotation circuit has faired slightly better than the milling plant in keeping abreast with technology The small 45 ft Agitair cells of the 1950s were all replaced by 300 cubic feet Wemco cells in

New approach for flotation process modelling and

2020年9月1日 The most common approach in a single flotation cell consists of using a perfect mixing model, because of its simple representation and mathematical treatment. An alternative approach such as the LSTS model (large and small tank in series) has proven to be useful particularly for self-aspirating cells.

Froth recovery measurement in plant scale flotation cells

2003年11月1日 Over recent years a number of techniques have been developed as part of the AMIRA 2 P9 project to represent mathematically or measure directly sub-processes occurring in flotation cells. These include the determination of: • a machine parameter (bubble surface area flux, S b); a froth parameter (froth recovery, R f); entrainment and

Flotation of PGM-containing minerals: Plant-wide

2013年12月1日 This section briefly presents the methodology followed when developing a flotation circuit model which is then fitted to available plant data. The methodology consisted of the following steps: 1. Review collected data and compile a model training data set. 2. Configure circuit flow sheet in the Cycad process modelling package. 3.

Froth recovery measurements in an industrial flotation cell

2013年11月1日 Flotation is a complex separation process that exploits the physicochemical surface properties of mineral particles to separate the valuable minerals from the waste rock. It is widely used for beneficiation of ores such as metallic sulphides, feldspar, mica, salt minerals and cassiterite along with industrial minerals.

Machine vision based monitoring of an industrial flotation

2014年12月10日 1. Introduction. Flotation is a physico-chemical separation process that utilizes the difference in surface properties of the valuable minerals and the unwanted gangue minerals (Wills and Napier-Munn, 2006).In a flotation cell, already conditioned fine particles with reagents (i.e. collectors and frothers) are subjected to air bubbles and the

Froth flotation process and its application Wiley Online

2021年2月5日 The components of a flotation system are (figure 1): Cell: A container that contains an impeller and is competent to retain the solids in suspension. It also provides aeration for frequent air bubble- particle collision. Feed: The pipe that is used to supply materials i.e. flotation pulp to the cell. Flotation pulp: A mixture of solids (to be

Design and construction of a continuous pilot flotation

2022年11月7日 1.Introduction. Flotation is largely dependent on differences in surface wettability of valuable species and gangue in an aqueous slurry or pulp (Hanumanth and Williams, 1988).The surfaces of valuable particles are either inherently hydrophobic by natural surfactants or selectively rendered to be hydrophobic by an additive—synthetic

Cryo-EM structure of gas vesicles for buoyancy-controlled

2023年3月2日 Aquatic bacteria and archaea have evolved mechanisms to regulate buoyancy and can—similar to ballast tanks in submarines—create and eliminate gas-filled compartments to allow vertical migration in the water column. The cellular compartments providing positive buoyancy are formed by gas-filled protein shells called gas vesicles

Minerals Free Full-Text Investigations on Single Minerals

Notice. You are accessing a machine-readable page. In order to be human-readable, please install an RSS reader.

testablishing a small flotation cell plant 123chauffage.fr

The effect of underground mine water on performance of the . Hardinge conical ball mills 6 of the small mills have since been replaced by two 14 ft x 18 ft Vecor mills The flotation circuit has faired slightly better than the milling plant in keeping abreast with technology The small 45 ft Agitair cells of the 1950s were all replaced by 300 cubic feet Wemco cells in

الآلات القديمة مومباي آلات طحن

mining excavators for sale

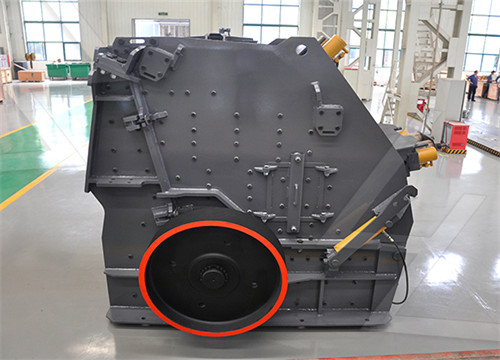

كسارة المطرقة موديل SPC

impact hammer for 1312 crusher vietnam

mineral processing and beneficiation ppt

مزايا الطحن العمودي

تحميل مجاني آلة محطم-التحميل لعبة محطم القرميد

اتصل بنا معمل تعدين رمال الحديد الرمل السوري

مطحنة مطرقة طن للبيع

پردازش میل توپ طلا

نوع الطحن غير المركزي من الصور والمواصفات

gold mining equipment edmonton edmonton area

York Potash and Parish training

تركيب الكسارة المحورية في كسارة

منبع گیاهی صفحه نمایش با کیفیت بالا

مصنع لكسارة الصخور

ما هو الفحم القاري والفرعي

تخطيطي لكسارة الصخور المحمولة

crawler crusher from germany pdf-Crawler jaw crusher for iron mining Germany

تعدين المحجر المركزي في المملكة العربية السعودية

hammer mills price uk

المصنعين والموردين من الأجهزة في الصين

blow out tower iodine plant

مصنع لتصنيع الرماد المتطاير في chitradurga

stone crusher south korea for sale

920 workers affected by cement plant shutdown dangote

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20