الحار منتجات

ملكنا الإخبارية

grinding spiral bevel gear cutting

An integration method of design and machining for spiral

2020年9月25日 The proposed integrated design and machining mode accomplishes the isolated-to-integrated transformation of spiral bevel gear machining mode based on

Roughness model for tooth surfaces of spiral bevel gears

2016年10月1日 The grinding wheel follows the shape of a generating gear that is supposed to engage with the machined gear. So the general orthogonal grinding mechanism and

Gear Grinding Bevel Gear Custom Manufacturer

Chamol’s gear grinding experience can trace back to the first gear grinding machine in 1968. For decades, after continuous acquisitions, increased investment, and training, we have

Research on the cutting dynamics for face-milling of spiral

2020年12月22日 This stone describes a face-milling method for generation of noncircular spiral bevel gears, which is analogous to the generation of spiral bevel and hypoid gears

Spiral Bevel and Hypoid Gears Jstor

rate finish grinding of hardened spiral bevel and hypoid gears has been developed. The use of cubic boron nitride (CBN) grinding wheels permits rapid metal removal rates and long

Spiral Bevel and Hypoid Gear Cutting Technology Update

2022年2月19日 Spiral bevel and hypoid gear cutting has changed significantly over the years. The machines, tools, processes and coatings have steadily advanced to the

Bevel Cutting Tools Gleason Corporation

The latest Gleason developed Pentac Ecoblade RT Cutter System preserves the advantages of positive seated Pentac Blades, real axial and radial truability. A newly invented spacer block design provides the

Grinding Spiral Bevel Gears Modern Machine Shop

2015年9月29日 Grinding Spiral Bevel Gears Deep in the heart of Texas, there’s a company making high-quality spiral bevel gears by grinding them straight from a blank, and using a

Gears Rave Gears and Machining

2023年3月2日 We have a wide range of spiral bevel cutting, finish grinding and grind from solid capabilities. Rave Gears and Machining can produce your spiral bevel gears,

Analysis model for surface residual stress distribution of

2018年12月1日 A grinding test of spiral bevel gear was carried out under the following grinding parameters: the generation velocity is 3.1 m/s, the grinding velocity is 14 m/s, the depth of cut is 0.02 mm. The residual stress on the gear surface were measured by

An integration method of design and machining for spiral

2020年9月25日 As illustrated in Fig. 1, by building a communication network environment, the design, CNC machining based on universal CNC machine tools, digital inspection and correction of spiral bevel gears can be organically integrated through the information communication and management technologies.Particularly, the distributed numerical

Research of grinding process of gears with involute profile

2018年3月1日 Grinding as final processing exerts great influence on quality and accuracy of a surface layer of gears. Gear grinding is the most productive method of abrasive processing providing gears of 3 8 degrees of accuracy. USA) New approach to the local synthesis of spiral bevel gears 13-17. Entelis S G and Berliner E M 1995 The lubricant

Mathematical Model for Grinding a Stick Blade Profile to

2019年11月11日 This study uses a 5-axis profile grinder to grind the stick blade. The machine settings for the profile grinder and the corresponding grinding wheel geometry are derived for the grinding of each face of the stick blade. A sensitivity analysis for the machine settings is conducted to determine the accuracy of the profile grinder.

Gear Mathematics for BevelHypoid Gears Gear

2022年2月19日 it is used in industrial gear boxes; the reader will be able to apply the derivations to any other bevel and hypoid gearset. With the results of each calculation step, basic settings are computed as they are commonly used by modern CNC bevel gear generators in order to cut or grind real bevel gearsets. —Hermann J. Stadtfeld

A Digital Twin-Based State Monitoring Method of Gear

2023年3月4日 The geometric parameters of the testing spiral bevel gears are shown in Table 1, while the test bench of spiral bevel gear fatigue life is shown in Figure 10. The test process is as follows: firstly, the gear meshing running time is half an hour under one-fourth, one-half, three-fourths, and full of the brake torque, respectively.

Gears Rave Gears and Machining

2023年3月2日 We have a wide range of spiral bevel cutting, finish grinding and grind from solid capabilities. Rave Gears and Machining can produce your spiral bevel gears, whether it’s a high volume low precision gears or critical high-performance spiral bevel gear set. Please review this chart below: Spiral Bevel Gear Grinding on Klingelnberg G60 Rave

Cutting Spiral Bevel Gears On A Five-Axis

2009年9月23日 A five-axis HMC can also be used for spiral bevel gears. The company reports that an HU80A-5X horizontal machining center, one of its largest five-axis models, is producing these gears in diameters as

Spiral Bevel Gear testing before harden. CM Gear Cutting.

#malaysia #lathe #engineering #gear #machanical #cnc #viral #hobbing #machinist

Analysis model for surface residual stress distribution of

2018年12月1日 The grinding process of spiral bevel gear is based on the simulation of the grinding wheel and the meshing of the machined gear. In the grinding process, the surface of the grinding wheel is represented by a conjugate surface which is meshed with the machined tooth surface [8], [9].

An integration method of design and machining for spiral

2020年9月25日 As illustrated in Fig. 1, by building a communication network environment, the design, CNC machining based on universal CNC machine tools, digital inspection and correction of spiral bevel gears can be organically integrated through the information communication and management technologies.Particularly, the distributed numerical

Research of grinding process of gears with involute profile

2018年3月1日 Grinding as final processing exerts great influence on quality and accuracy of a surface layer of gears. Gear grinding is the most productive method of abrasive processing providing gears of 3 8 degrees of accuracy. USA) New approach to the local synthesis of spiral bevel gears 13-17. Entelis S G and Berliner E M 1995 The lubricant

Gear Grinding Bevel Gear Custom Manufacturer

Gear surface grinding Excircle grinding Internal grinding Plane grinding Spline grinding Shaft grinding modulus: 2 35 Max. diameter: 1800mm max. face width: 380mm precision: DIN Class 4 roughness: Ra. 0.4 Gear grinding equipment Download the complete equipment list

Gear Mathematics for BevelHypoid Gears Gear

2022年2月19日 it is used in industrial gear boxes; the reader will be able to apply the derivations to any other bevel and hypoid gearset. With the results of each calculation step, basic settings are computed as they are commonly used by modern CNC bevel gear generators in order to cut or grind real bevel gearsets. —Hermann J. Stadtfeld

A Digital Twin-Based State Monitoring Method of Gear

2023年3月4日 The geometric parameters of the testing spiral bevel gears are shown in Table 1, while the test bench of spiral bevel gear fatigue life is shown in Figure 10. The test process is as follows: firstly, the gear meshing running time is half an hour under one-fourth, one-half, three-fourths, and full of the brake torque, respectively.

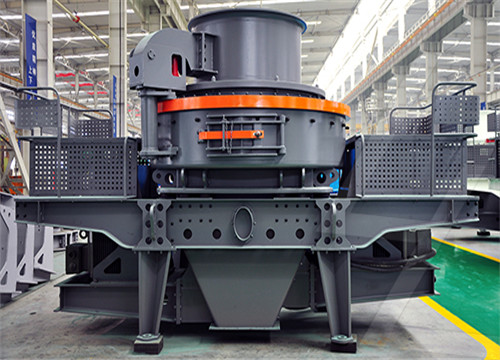

تصميم تصميم كسارة مخروطية جزء لكل تريليون

سيور النقل

آلة تجعيد الشركة المصنعة لشبكة كسارة الحجر تركيا

used bridgeport milling machines for sale uk-Bridgeport milling For sale

تعدين الذهب الغريني أفريقيا طحن مطحنة الصين

مطحنة الأسمنت المثبط الرفع

آلة طحن الباريت لل

كسارة دوارة لمصنع الأسمنت

الأنشطة في مصنع للاسمنت من سحق ل-في س هو سحق ل

افضل موقع امريكي لبيع المعدات الثقيله

used limestone impact crusher manufacturer in brazil

كسارة تصادم أجزاء وظيفة قضيب النفخ

گیاهان زغال سنگ برق خرد کردن

mining magnetic separation methods

汉中市综合医院-陕西农业农村网

اليميتادور فيباتوريو

roll mill import jaw crusher bandung

混凝土振动器-戳一戳了解成都彩色透水地坪工程效果

grinding mill discharge density-Ball Mill Design Power Calculation

مصنع كسارة متنقلة عالية الكفاءة وعالية الجودة

vertical roller mill grinder offset rollers-printing roller grinding equipment

无底粉碎机

روبو الرمال سعر الآلات في المملكة العربية السعودية

jaw crusher gap adjustmentri

للبيع كسارة صخرية في اليمن

concrete plants for sale

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20