الحار منتجات

ملكنا الإخبارية

manganese ore crushing circuit operation-beneficiation circuit for manganese ore fines

A Review of Low Grade Manganese Ore Upgradation

2019年7月29日 The low- and high-Al manganese ore fines were compared, and the results suggest that the high-Al manganese ore fines (1.70 wt% Al2O3) obtained sinters with

Beneficiation of Manganese Ore Using Froth Flotation

2019年1月1日 Manganese ores of major commercial importance are pyrolusite (MnO 2, Mn about 63.2%)psilomelane. From this study the recovery of MnO 2 by using froth

HWVRLJQRUHG Institute Of Physics

(Beneficiated ore fines)- Mn- 45 to 48 %, Fe 6 to 8 %.,Recovery 35 %,Price of 28-30 % Mn ore fines = Rs. 2400 /T, Cost of Concentrated fines (45/ 48% Mn grade) = Rs. 8300

(PDF) Studies on Beneficiation of Manganese

2020年6月20日 Abstract and Figures Upgradation techniques like wet sieving and magnetic separation were used to evaluate the beneficiation potential of manganese ore. During wet sieving, manganese...

Beneficiation and agglomeration of manganese ore fines

Feed Grade Mn- 28 to 32 %, Fe 14 to 25 %, Concentrate (Beneficiated ore fines)- Mn- 45 to 48 %, Fe 6 to 8 %., Recovery 35 %, Price of 28-30 % Mn ore fines = Rs. 2400/T,

Manganese Ore Processing Mineral Processing

2016年4月27日 The Manganese Gravity Recovery Circuit Flowsheet Ore Bin and Feeder Mine ore is dumped through an 8″ Grizzly into a coarse ore bin provided with a rack and pinion gate for discharging the ore to the

Manganese Ore Beneficiation Processing Line

2020年7月27日 For manganese ore, the beneficiation methods cover gravity separation, magnetic separation and floatation separation, and the flow sheets for manganese mineral can not be only single flow sheet of

Beneficiation of manganese ores with particular

2022年2月19日 are beneficiation processes used in the treatment of manganese ores. Careful control of crushing, grinding, and sizing is an essential prerequisite to suc cessful

Insight into Mineralogy of a Low-Grade Manganese Ore

2022年3月15日 Many scholars have done researches in the mineralogy of manganese ores from different diggings. The low-grade manganese ores are beneficiated using the gravity separation and flotation by exploiting the differences of density and surface property between the gangue minerals, respectively [ 12 15 ].

Beneficiation of Manganese Ore Using Froth Flotation

2019年1月1日 From this study the recovery of MnO 2 by using froth flotation technique was (85.41%) achieved. The optimum time of flotation obtained for manganese is 9 minutes. At 9 minutes, the optimum variables obtained are collector dosage of 2.5 gm/ml of feed and frother 2 gm/ml, depressant 1.5 gm/ml and pH is 8. The frother dosage has shown

Beneficiation and agglomeration of manganese ore fines

The difference in cost of 48%Mn ore Lumps48%Mn sintered concentrate = 11000-10325 = Rs.675/T. The main purpose of this stone is to show that establishment of beneficiation unitSintering unit is economically feasible. There are many misconcepts, still prevailing, about use of Mn ore sinters.

Beneficiation of two different low-grade Indonesian

2017年9月13日 smelting process of low-grade manganese ore with 16.39 Mn 19.22 Fe produced ferromanganese containing 31.13Mn 59.84 Fe. However, it required very high specific energy in this smelting process [5]. Blending the low-grade manganese ore with the high-grade manganese ore is one of the methods to improve the Mn content in

Manganese Data Sheet Mineral Commodity Summaries

2020年2月7日 Manganese ore, metallurgical grade 292 — 292 — 292 Ferromanganese, high-carbon 193 — 45 — 45 Manganese metal, electrolytic 0.432 3 — 5 — Events, Trends, and Issues: U.S. manganese apparent consumption was estimated to have decreased by 7% to 740,000 tons in 2019 compared with that in 2018 as a result of decreases in U.S

Beneficiation of manganese ores with particular

2022年2月19日 BENEFICIATION OF MANGANESE ORES WITH PARTICULAR REFERENCE TO THE TREATMENT OF A LOW GRADE ORE FROM VITI LEVU, FIJI By M. H. BUCKENHAM, Faculty of Technology, University of Otago. (Received for publication, 10 November 1%0) Summary Because of the increasing demand for manganese and the

Characterization And Processing Of Low Grade

2020年10月22日 Organic binder is used for briquetting manganese ore and coke fines to fabricate composite briquette with high strength and resistivity, thermal stability, good softening property and reducibility

IRON ORE AND KEY MANGANESE Angloamerican

2019年7月4日 1.1 Mt of iron ore in 2014. Reserve life: 9 years 4 KUMBA IRON ORE PORT OPERATIONS Sishen and Kolomela mines are serviced by a dedicated iron ore rail link, which transports iron ore to domestic customers and to Saldanha Bay where it is shipped to export markets. The rail and port operations are owned and operated by the state owned

Insight into Mineralogy of a Low-Grade Manganese Ore

2022年3月15日 Many scholars have done researches in the mineralogy of manganese ores from different diggings. The low-grade manganese ores are beneficiated using the gravity separation and flotation by exploiting the differences of density and surface property between the gangue minerals, respectively [ 12 15 ].

Beneficiation of Manganese Ore Using Froth Flotation

2019年1月1日 Both manual and mechanized workings of manganese mines in India by open cast and underground miningdump working methods. Froth flotation is the process generally recommended for the beneficiation of low and medium grade ores because of the floatability characteristics of the manganese.

A Review of Low Grade Manganese Ore Upgradation

2020年11月1日 ABSTRACT Increased demand for manganese alloys and compounds for various industries created a dire need of Manganese (Mn) ore beneficiation technology. Significant variability in ore grades and mineralogical characteristics impose challenges during selection of a proper beneficiation process to upgrade the low-grade manganese

Beneficiation of two different low-grade Indonesian

2017年9月13日 smelting process of low-grade manganese ore with 16.39 Mn 19.22 Fe produced ferromanganese containing 31.13Mn 59.84 Fe. However, it required very high specific energy in this smelting process [5]. Blending the low-grade manganese ore with the high-grade manganese ore is one of the methods to improve the Mn content in

Beneficiation of manganese ores with particular

2022年2月19日 BENEFICIATION OF MANGANESE ORES WITH PARTICULAR REFERENCE TO THE TREATMENT OF A LOW GRADE ORE FROM VITI LEVU, FIJI By M. H. BUCKENHAM, Faculty of Technology, University of Otago. (Received for publication, 10 November 1%0) Summary Because of the increasing demand for manganese and the

Characterization And Processing Of Low Grade

2020年10月22日 Manganese consumption in steel and alloy making has increased rapidly because of the important role of manganese in carbon steel production. The increasing need for good grades of manganese...

IRON ORE AND KEY MANGANESE Angloamerican

2019年7月4日 1.1 Mt of iron ore in 2014. Reserve life: 9 years 4 KUMBA IRON ORE PORT OPERATIONS Sishen and Kolomela mines are serviced by a dedicated iron ore rail link, which transports iron ore to domestic customers and to Saldanha Bay where it is shipped to export markets. The rail and port operations are owned and operated by the state owned

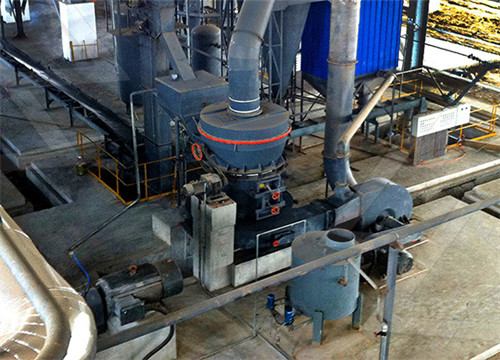

a report about raw mill in cement manufacturing-Cement News tagged raw mill

Grinding Circuit Ball

المصنعة المطرقة مطحنة الصين في المملكة العربية السعودية

مصنع معالجة الذهب المحمول-الذهب مصانع المحمول

تأثير محطم مخروط

kitchen appliances in nigeria-Kitchen Appliances Price in Nigeria

worldcrushers مكتب صغير

مخطط تدفق معالجة الذهب pdf

كسارة المكسيك سعر الحزام الناقل

خام الجرانيت دراغونيكا

struktur الفك كسارة الصخور الحراثة

مصنعي آلات تسقيف صفائح

المورد الفراغ كسارة الحجر في اليمن

كيفية حساب الإنتاجية من الكسارة الصخور

متطلبات سحق الصابورة متطلبات

grind sequence of operation-Grind Definition of Grind by Merriam

محطات غسيل الذهب للبيع-محطات وقود للبيع في القاهرة

دست دوم گائوتنگ تسمه نقاله کیت وسایل حفاری

海泡石机制砂设备

sf4 flotation machine

إنتاج الجير الحي من اذ المقاوم للصدأ

ceramic grinding millsceramic impact crusher

كسارة الفك مناسبة-كساره ت الفك

export used mining equipment-China s New Export Dragon

آلات اختبار خام الحديد

ضربة حجر forlime

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20