الحار منتجات

ملكنا الإخبارية

cement grinders vertical roller mill energy

Modeling of energy consumption factors for an industrial

2022年5月9日 The raw vertical roller mill has four rollers, 3000 KW main drive, 4.8 m table diameter, 2.16 m roller diameter with 330 t/h capacity (made by LOESCHE Company

Operational parameters affecting the vertical roller mill

2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power

Energy-Efficient Technologies in Cement

2016年10月5日 Vertical roller mills are developed to work as air-swept grinding mills. Roller mills are operated with throughput capacities of

(PDF) Performance Evaluation of Vertical Roller

2017年9月11日 Grinding and separation efficiency of vertical roller mill were evaluated. In addition to these, performance figures of vertical roller

Review on vertical roller mill in cement industryits

2021年1月1日 Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption,

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energy-efficiency Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs.

An energy based comparison of vertical roller mills and

2015年3月10日 The vertical roller mill equipped with an internal classifier is often said to be more energy efficient than tumbling mills working on the same material and the same

PROCESS CONTROL FOR CEMENT GRINDING IN

2017年10月27日 The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power

CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS

2019年9月12日 CEMENT 6 SikaGrind® FOR VERTICAL ROLLER MILLS SikaGrind® FOR SLAG CEMENT Granulated blast-furnace slag (GBFS or GBS) is a by-product of the

[PDF] Cement grinding Vertical roller mills versus ball mills

For several decades the cement industry has successfully utilized vertical roller mills (VRM) for grinding of raw materials and solid fuels. Most recently, this technology has been

Modeling of energy consumption factors for an industrial

2022年5月9日 The raw materials were mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill). The raw vertical roller mill has four rollers, 3000 KW main drive, 4.8 m table diameter, 2.

Operational parameters affecting the vertical roller mill

2017年4月1日 The model shall enable the prediction of the throughput, the particle size distributions around the vertical-roller-mill circuit, the specific energy consumption and in a later stage the wear to be expected in dependency of ore treated. The model combines performance data from pilot and industrial plants with mineral characterization methods.

(PDF) Performance Evaluation of Vertical Roller

2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the

CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS

2019年9月12日 FOR VERTICAL ROLLER MILLS The cement industry contributed a significant share to the progress of the concrete technology: ́ Good and long lasting workability energy of a cement plant. Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press.

PROCESS CONTROL FOR CEMENT GRINDING IN

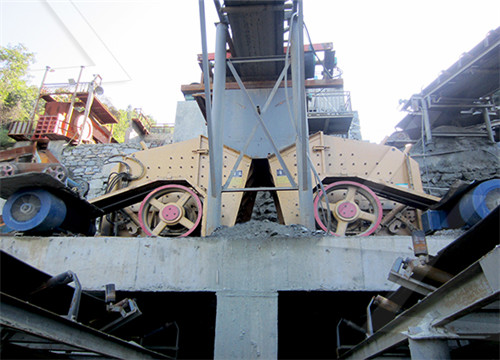

2017年10月27日 38]. Various grinding laws, energy relationships, control factors and controller design for cement grinding are discussed in [37]. Figure-1. Vertical roller mill for cement grinding [13]. VRM shown in Figure-1 uses hydraulically hard-pressed conical shape 2-4 rollers against the horizontal revolving grinding table. To enhance comminution, the

IOP 287 Praveen Purshottaaim Parieek Institute Of

Increase productivity of vertical roller mill using seven QC tools Praveen Pareek1 and Dr. Vijayendra Singh Sankhla1 1 Department of Mechanical Engineering, GITS, Udaipur, India. Email: praveen.parieek@gmail Abstract. Cement sector in india is enjoyign success and capacity enhancement due to the

VRMs on the up

Overall vertical roller mill sales in 2016 were above the long-term market trend, highlighting the importance of ’s position as a lead supplier for VRMs in the cement industry. The strong market for VRMs is mostly driven by ongoing emphasis on energy efficiency in the global cement industry and continuing growth in developing markets.

Raw Material Drying-Grinding Cement Plant Optimization

Vertical roller mills can typically handle an aggregate moisture of up to 20% in raw materials and consumes about 30% less power in grinding. Hence it is commonly preferred for grinding operation in new plants of higher capacities. However, many ball mills are still in

Modeling of energy consumption factors for an industrial

2022年5月9日 In the mid-1990s, the vertical roller mill (VRM) was introduced to the cement industry to reduce this energy usage. Besides lowering power consumption, VRMs may improve process capacity...

Operational parameters affecting the vertical roller mill

2017年4月1日 The model shall enable the prediction of the throughput, the particle size distributions around the vertical-roller-mill circuit, the specific energy consumption and in a later stage the wear to be expected in dependency of ore treated. The model combines performance data from pilot and industrial plants with mineral characterization methods.

(PDF) Performance Evaluation of Vertical Roller

2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the

CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS

2019年9月12日 FOR VERTICAL ROLLER MILLS The cement industry contributed a significant share to the progress of the concrete technology: ́ Good and long lasting workability energy of a cement plant. Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press.

PROCESS CONTROL FOR CEMENT GRINDING IN

2017年10月27日 38]. Various grinding laws, energy relationships, control factors and controller design for cement grinding are discussed in [37]. Figure-1. Vertical roller mill for cement grinding [13]. VRM shown in Figure-1 uses hydraulically hard-pressed conical shape 2-4 rollers against the horizontal revolving grinding table. To enhance comminution, the

SUCCESS Gebr. Pfeiffer

2021年11月10日 cement grinding from type MPS to MVR mill. Nearly 70 MVR mills for cement grinding are currently in operation or under order execution. Achieving the same quality of cement produced in ball mills was essential for the success of the vertical roller mill. Originally, the goal was to achieve the same or similar particle size distribution (PSD).

VRMs on the up

Overall vertical roller mill sales in 2016 were above the long-term market trend, highlighting the importance of ’s position as a lead supplier for VRMs in the cement industry. The strong market for VRMs is mostly driven by ongoing emphasis on energy efficiency in the global cement industry and continuing growth in developing markets.

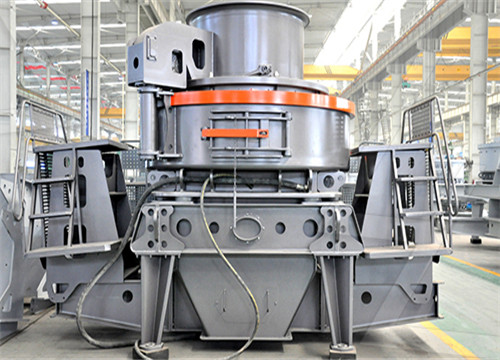

Vertical Cement Mill, Vertical Roller Mill Buy Cement Mill

The vertical cement mill is large-scale cement grinding machine. With advantages of energy-efficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc. As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading

stone clushing line price

sand stone dry mill

شاشة تهتز بقطر 36 بوصة

كسارة مركب من الحجر الجيري

مطحنة مطرقة للبيع الجزائر

بوصة حصى مطحون

خلط الرمل محطة الغسالة

تكلفة كسارة دلو

مصنع الجميح للسيارات المستعملة للبيع في سري لانكا-مؤشر الأسعار

illegal sand mining in south africa

چقدر بازیگران از طلا عجله آلاسکا پرداخت

الرسم البياني محطة إثراء خام الحديد

وظيفة المملكة العربية السعودية للكسارة الدورانية

small portable gold ore rock crushers premier

crusher ready stock di surabaya

المكونات الفردية لآلة grinfing

مطحنة مسحوق الجبس

نظم معالجة خام الذهب التعويم

تكلفة كسارة خام الذهب

برای دستگاه شماره گیری مجدد و نایلون سنگ زنی تایر

used america rock crusher for sale

josephine county oregon patented gold claims for sale

طواحين 50tph الكرة

معدات مصنع اسمدة للبيع

الكرة الصغيرة مطحنة مسحوق أسود للبيع

الذهب كسارة مخروطية متنقلة الموردين في ماليزيا

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20