الحار منتجات

ملكنا الإخبارية

iron ore slag cement crusher plant in colombia

The six main steps of iron ore processing Multotec

3. Feeding the crusher (Reclaim) The surge pile allows a constant supply of material to be fed into the mill, which ensures consistent results and stability in the ore recovery

Iron Crushing Line, iron ore crushing plant, iron ore

2022年2月22日 Crusher produces several series iron ore crushers, of which jaw crusher, impact crusher and mobile crusher fits for processing this ore best. export to

CNA Aerated bricks prepared from iron ore

According to a preparation method of the concrete bricks, iron ore slag is taken as a raw material; firstly, iron ore slag is subjected to grinding with water in a ball grinder so as to

Cement Crusher Crusher In Cement Plant AGICO Cement

AGICO Cement is a Chinese company that specialized in manufacturing and exporting cement production lines and cement equipment, providing turnkey projects that cover

Cement Crusher For Sale Jaw Crusher, Cone Crusher

Cement crusher refers to the stone crusher in the cement industry, as a part of the cement plant, it plays a vital role in the cement production line. Before sending it into the raw mill

Iron Ore Slag Crushing Plant at Rs 800000

01. Iron Ore Slag Crushing Plant's turnkey solutions are offered by us, Star Trace .We are one of the leading project suppliers for Iron Ore Slag Crushing Plant and we work closely with our customers to full fill their

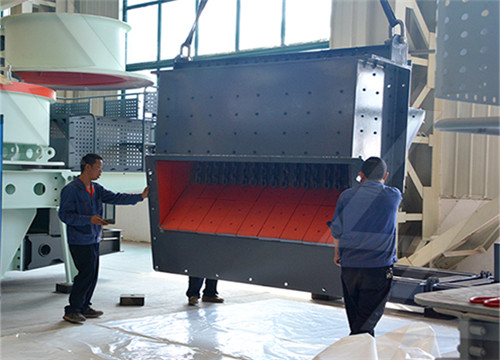

[Hot Item] Mining Industry Vertical Cement/Slag/Iron Ore

2023年2月7日 Mining Industry Vertical Cement/Slag/Iron Ore Crusher, Find Details and Price about Copper Ore Crusher Slag Crushing Machine from Mining Industry Vertical

mill/sbm iron ore seperating slag cement crusher plant in

Contribute to crush2022/mill development by creating an account on GitHub.

Iron ore BHP

There are four main types of iron ore deposit: massive hematite, which is the most commonly mined, magnetite, titanomagnetite, and pisolitic ironstone. These ores vary in colour from dark grey, bright yellow, or deep purple to

Iron and Steel Slag Statistics and Information USGS

The iron ore is a mixture of iron oxides, silica, and alumina. From this and the added fluxing agents molten slag and iron are formed. The physical characteristics such as density, porosity, and particle size, are affected by the cooling rates and chemical composition.

Recovering Iron from Iron Ore Tailings and

2019年4月15日 Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore concentrate. In this , iron recovery from IOTs was studied at different points during a process

Blast Furnace Slag an overview ScienceDirect Topics

2017年10月18日 10.2.2 Blast furnace slag. Blast furnace slag (BFS) is a by-product from iron production in blast furnaces, which are fed by a mixture of iron-ore, coke and limestone. In the process, the iron ore is reduced to iron while all remaining materials form the slag, which is tapped off as a molten liquid and cooled.

Redalyc.NATURAL RESOURCES SUSTAINABILITY: IRON

2015年3月24日 The scope of the proposed tool includes various processes such as iron extraction (mining) and transformation into blast furnace raw material (ore processing and transport). First, a brief description of the method is provided, and the influence of distinctive characteristics and the weightings of the main parameters are explained.

Processing and Reusing Technologies for Steelmaking Slag

2013年9月4日 The yield of iron/steel slag is about 300 kg/t-p per ton of pig iron for blast furnace slag and about 100-150 kg/t-s per ton of molten steel for steelmaking slag. In Japan, some 40 million tons of iron/steel slag are presently produced annu-ally (Table 1). Technology UDC 669 . 054 . 82 : 669 . 184 . 244 . 66 * Department Manager, Planning

12.5 Iron And Steel Production US EPA

2015年9月10日 The production of 1 ton of iron requires 1.4 tons of ore or other iron bearing material; 0.5 to 0.65 tons of coke; 0.25 tons of limestone or dolomite; and 1.8 to 2 tons of air. Byproducts consist of 0.2 to 0.4 tons of slag, and 2.5 to 3.5 tons of blast furnace gas containing up to 100 pounds (lb) of dust.

Slag crushingprocessing-LIMING Mining and Rock

2023年2月21日 Applications. Slag processing equipments can supply crushing, magnetic separation, separation, grinding and other deep-processing. First isolated particles can be melted steel making, the rest of the coarse particles used as motorways gravel aggregate material, crushed into fine slag powder can be elected iron powder, the rest was used for

Category Title NFR SNAP 0402 ISIC Version European

2019年11月4日 The production of iron, more specifically the use of carbon to convert iron ore to iron is a major source of carbon monoxide (CO), carbon dioxide (CO 2) and NMVOCs. Figure 2.4 describes the iron-making process Sintering Process Sinter (used in Pig Iron Production) Coke Breeze Fuel Chapter 1.A.2.b Iron Ore

ru/eand ploration mining iron ore В Малайзии.md at main

Contribute to kokiulinjsb/ru development by creating an account on GitHub.

Iron ore BHP

There are four main types of iron ore deposit: massive hematite, which is the most commonly mined, magnetite, titanomagnetite, and pisolitic ironstone. These ores vary in colour from dark grey, bright yellow, or deep purple to

Iron and Steel Slag Statistics and Information USGS

The iron ore is a mixture of iron oxides, silica, and alumina. From this and the added fluxing agents molten slag and iron are formed. The physical characteristics such as density, porosity, and particle size, are affected by the cooling rates and chemical composition.

Recovering Iron from Iron Ore Tailings and

2019年4月15日 Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore concentrate. In this , iron recovery from IOTs was studied at different points during a process

(PDF) Iron Ore Slag Dust and Cement Block

2022年1月18日 Iron Ore Slag Dust and Cement Block. January 2022. Divyarth Manas. This research stone represents the experimental study on use of iron ore slag dust material as an aggregate in concrete. To

Processing and Reusing Technologies for Steelmaking Slag

2013年9月4日 The yield of iron/steel slag is about 300 kg/t-p per ton of pig iron for blast furnace slag and about 100-150 kg/t-s per ton of molten steel for steelmaking slag. In Japan, some 40 million tons of iron/steel slag are presently produced annu-ally (Table 1). Technology UDC 669 . 054 . 82 : 669 . 184 . 244 . 66 * Department Manager, Planning

Iron Ore Pelletizing Process: An Overview

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low

Ironmaking 101 From Ore to Iron with Blast

2017年10月10日 The carbon in the coke reacts with the oxygen to produce a reducing gas, carbon monoxide (CO) according to the following reaction: 2 C (s) + O 2 (g) → 2 CO + Heat. In the upper region of the blast furnace

12.5 Iron And Steel Production US EPA

2015年9月10日 The production of 1 ton of iron requires 1.4 tons of ore or other iron bearing material; 0.5 to 0.65 tons of coke; 0.25 tons of limestone or dolomite; and 1.8 to 2 tons of air. Byproducts consist of 0.2 to 0.4 tons of slag, and 2.5 to 3.5 tons of blast furnace gas containing up to 100 pounds (lb) of dust.

Slag crushingprocessing-LIMING Mining and Rock

2023年2月21日 Applications. Slag processing equipments can supply crushing, magnetic separation, separation, grinding and other deep-processing. First isolated particles can be melted steel making, the rest of the coarse particles used as motorways gravel aggregate material, crushed into fine slag powder can be elected iron powder, the rest was used for

Cone Crusher Used in Pakistan Iron Ore Mining Sbmchina

2023年1月19日 This crusher has a variety of methods, and can match with other equipment quickly. Overall, using this cone crusher for crushing iron ore has the following advantages: 1 It has good performance for crushing iron ore and other minerals which is difficult to process. 2 The finished grain type is good. And the crusher is with high

كسارة أولية لشكل قطع غيار التعدين

كسارة الفك الصين تكلفة

التعدين حزب العمال سام

آلة طحن شجرة مياوم ي

آلة قطع وتجعيد الكرتون giga lx manul

مطرقة طحن مصنعين مطحنة-ريموند مطحنة بيع استخدام

启隆研磨-研磨拋光石 啟隆科技有限公司

خط الجبس إنتاج كتلة إيران-خط انتاج تدوير المواد

تعبئة آلة في الجزائر

أنواع طحن الحجارة

جداساز مغناطیسی خوب معدنی خوب برای فروش

نمودار فرآیند نیروگاه استخراج طلا

تستخدم أجزاء كسارة الحجر

stone crusher for sale in sri lanka

دلو محطم فرنك بلجيكي-الات البناء والتشييد

crusher specs in peru

cast mining equipment for sale south africa-Appropriate Process Technologies

كسارة الحجر الهندى المصغرة

طحن مطحنة نفاثة الكربون المنشط

سعر كسارة النحاس الفكية في كولومبيا

placer gold wash plant 200 yard per hour

تأجير كسارة الصخور لوس انجليس

لبيع كسارة الحجر في مصر

عينة البريد الإلكتروني تأكيد حضور ورشة عمل

معدات تكسير الحجارة المصنوعة في إنجلترا

سعر تكسير الصخور

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20