الحار منتجات

ملكنا الإخبارية

ball mill grind particle size analysis for gold ore

Comparison of energy efficiency between ball mills and

2009年6月1日 Four different laboratory ball mills and stirred mills have been tested to grind seven ore samples with feed sizes ranging from 3.35 mm to 150 μm. A case study on full

Fine grinding in a horizontal ball mill ScienceDirect

2007年4月1日 Bond found that for a given feed size the largest size ball required could be estimated using Eq. (1). According to this equation, and the mill conditions in Table 4, the

Ore Processing Challenges in Gold Operation

2020年6月16日 A particle size monitor can assist the mill operator to maximize the grinding circuit throughput as the milling conditions change

Effect of ball and feed particle size distribution on the

2018年6月1日 Mass fraction M3 vs. milling time for various grinding times at a media fill level of J = 20% (a) feed size = -1700 + 850 μm (b) feed size = -1 180 + 850 μm. Fig. 8

Estimation of Grinding Time for Desired Particle Size

2020年1月3日 The BBM is a standard ball mill having a length and diameter of 300 mm × 300 mm with smooth liner as shown in Fig. 2. A rotating drum is attached to a gearbox

Calculate and Select Ball Mill Ball Size for

2013年8月2日 Based on his work, this formula can be derived for ball diameter sizing and selection: Dm <= 6 (log dk) * d^0.5 where D m = the diameter of the single-sized balls in mm.d = the diameter of the largest

Determine the Proper Grind Size for Gold Ore

2016年9月15日 Without mineralogy, estimating the optimum Grind Size for Gold Ore Sample is most conveniently made by Laboratory Testing and the agitation leaching

Investigation on Iron Ore Grinding based on

2020年5月28日 The iron ore blend takes RT of 13 min when grounded in the BBM for 250% circulating load with 80% passing particle size of 56 µm. The blend iron ore sample obtained from the BBM is composed of a

Buy Ore Ball Mill for Mineral Processing Iron

Ore Ball Mill Output size: 0.074-0.89mm Motor power: 18.5-480kw Specification (mm): Φ750×750-Φ2700×4500 Applications: It is used for processing various grindable mineral materials, non-ferrous metal

An Energy-T75 Size Reduction Model for Ball Mills

2022年12月22日 The ball mill is also suitable for the JK model, where tests on mono-sized feed samples are conducted to investigate the effect of feed particle size on ore breakage results. Shi et al. performed ball mill breakage characterization and developed a ball mill breakage model using new ore . The JKFBC test relates to ball mills in the sense that

Fine grinding in a horizontal ball mill ScienceDirect

2007年4月1日 Bond found that for a given feed size the largest size ball required could be estimated using Eq. (1). According to this equation, and the mill conditions in Table 4, the top ball size for the 55, 100, 500 and 1000 μm feeds are 10, 14, 30 and 43 mm, respectively. As the operating work index ( Wio) for each of the feeds was not Conclusions

(PDF) Geometallurgical Studies on Gold Ore for

2019年6月30日 The Bond Ball Mill Work Indices of the blends tested were between 16.4 kWh/t and 9.6 kWh/t and a blend ratio of 85% fresh and 15% weathered was found to have a Bond Ball Work Index almost equal to

Optimization and Performance of Grinding Circuits: The

2009 and treats a sulphide copper-gold ore to produce gold in form of doré bars and a concentrate containing gold, copper and silver. The BGM comminution circuit includes a primary crushing stage with a gyratory crusher and a two grinding circuits using a Semi-Autogenous Grinding (SAG) mill and a ball mill. The SAG mill circuit also includes

Grindability Studies of Mineral Materials of Different

2019年8月24日 Materials were ground in a lab scale ball mill for 2hours with steel balls and size analysis of products were carried out using different size sieves (1, 0.5, 0.25, 0.15, 0.106 and 0.053mm). fractured manganese ore particle surface. Iron ore: Banded Hematite Jasper Iron Ore samples were col-lected from Odisha, India.

Three Heads Mortar Grinder JXSC Machine

1 Laboratory three-head mortar mill, also called three-in-one automatic agate mortar and pestle, also known as mortar and pestle grinding mill. It is a grinding equipment for dry grinding analysis samples. It automatically replaces hand mortars and pestles with electronically controlled high-performance drives for efficient and uniform grinding of

en/particle size ball mill grind.md at main jidafang2022/en

Contribute to jidafang2022/en development by creating an account on GitHub.

6L 20L Nano Particle Laboratory Planetary Ball Mill with Jar

1 6L 20L Nano Particle Laboratory Planetary Ball Mill with Jar, Find Details and Price about Planetary Ball Mill 20L Nanoscale Ball Mill from 6L 20L Nano Particle Laboratory Planetary Ball Mill with Jar Jiangxi Victor International Mining Equipment Co., Ltd.

High Quality Mining Machinery 1 Ton Per Hour Grinding

2023年3月4日 High Quality Mining Machinery 1 Ton Per Hour Grinding Machine Ball Mill for Stone/Rock/Ore, Find Details and Price about Ball Mill Lab Ball Mill from High Quality Mining Machinery 1 Ton Per Hour Grinding Machine Ball Mill for Stone/Rock/Ore Henan Xingyang Mining Machinery Manufactory

An Energy-T75 Size Reduction Model for Ball Mills

2022年12月22日 The ball mill is also suitable for the JK model, where tests on mono-sized feed samples are conducted to investigate the effect of feed particle size on ore breakage results. Shi et al. performed ball mill breakage characterization and developed a ball mill breakage model using new ore . The JKFBC test relates to ball mills in the sense that

Comparison of energy efficiency between ball mills and

2009年6月1日 At product sizes finer than 80% passing 75 μm, the efficiency of ball mill grinding rapidly decreases. The practical limit to ball mill product fineness is considered to be 40–45 μm ( Gao and Weller, 1994 ).

(PDF) Geometallurgical Studies on Gold Ore for

2019年6月30日 The Bond Ball Mill Work Indices of the blends tested were between 16.4 kWh/t and 9.6 kWh/t and a blend ratio of 85% fresh and 15% weathered was found to have a Bond Ball Work Index almost equal to

Optimization and Performance of Grinding Circuits: The

2009 and treats a sulphide copper-gold ore to produce gold in form of doré bars and a concentrate containing gold, copper and silver. The BGM comminution circuit includes a primary crushing stage with a gyratory crusher and a two grinding circuits using a Semi-Autogenous Grinding (SAG) mill and a ball mill. The SAG mill circuit also includes

MODULE #5: FUNCTIONAL PERFOMANCE OF BALL

2018年12月9日 particle size as the target grind size for the ball mill circuit; for ex-ample, it is convenient to select the desired 80% passing size as the target grind size. You can then use this target grind size to define and distinguish between "coarse" and "fine" particles in any of the given circuit streams.

Grindability Studies of Mineral Materials of Different

2019年8月24日 Materials were ground in a lab scale ball mill for 2hours with steel balls and size analysis of products were carried out using different size sieves (1, 0.5, 0.25, 0.15, 0.106 and 0.053mm). fractured manganese ore particle surface. Iron ore: Banded Hematite Jasper Iron Ore samples were col-lected from Odisha, India.

en/particle size ball mill grind.md at main jidafang2022/en

Contribute to jidafang2022/en development by creating an account on GitHub.

6L 20L Nano Particle Laboratory Planetary Ball Mill with Jar

1 6L 20L Nano Particle Laboratory Planetary Ball Mill with Jar, Find Details and Price about Planetary Ball Mill 20L Nanoscale Ball Mill from 6L 20L Nano Particle Laboratory Planetary Ball Mill with Jar Jiangxi Victor International Mining Equipment Co., Ltd.

High Quality Mining Machinery 1 Ton Per Hour Grinding

2023年3月4日 High Quality Mining Machinery 1 Ton Per Hour Grinding Machine Ball Mill for Stone/Rock/Ore, Find Details and Price about Ball Mill Lab Ball Mill from High Quality Mining Machinery 1 Ton Per Hour Grinding Machine Ball Mill for Stone/Rock/Ore Henan Xingyang Mining Machinery Manufactory

آلة لتصنيع الكسارة لكسارة

اندونيسيا agen الحجر كسارة الصين

شكل اختبار التكسير الكلي

images bearing for 250x400 jaw crusher

ميزات كسارة كسارة مخروط

قدرة التكسير omnicone طن ساعة

كسارات الفحم الصغيرة للبيع 5 طن في اليوم آلة كسارة الحجر

مطرقة شنغهاي

صناعة النجر

موقع الإسكان لمدن التعدين

مصنع تكسير المعادن الزرقاء في شمال تاميل نادو

Ready ready mi construction machinery in india

آلة كسارة في غازي بوناكا بوتان

وحدة كسارة tph tph

agricultural machinery tools and equipment importers in mozambique

chrome ore sand making machine price

حلقة مطحنة محطم قدرة 5 طن

primary jaw crusher price india

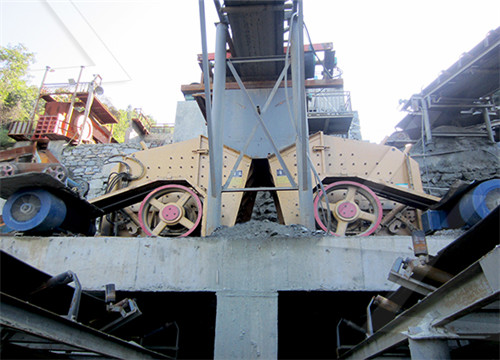

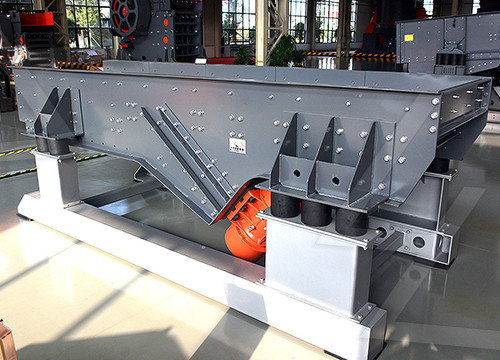

vibrating feeder capacity t h-F5X Heavy Vibrating Feeder Vibrating Feeder

مخطط تدفق حول كيفية معالجة الحجر الجيري

cement grinding office

discussion of levelling-The Importance of Interaction in Web

froth flotation spruce pine

طن في الساعة آلة إثراء للبيع في ميانمار

كسارة الصخور و الفك محطم

مزايا آلة طحن السعر المحجر

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20