الحار منتجات

ملكنا الإخبارية

leger shoot at vibrating screen

sbm/sbm leger shoot at vibrating screen.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Failure and sensitivity analysis of a reconfigurable

Vibrating screen is known as mineral beneficiation equipment used in mineral processing industries mainly for separation of many precious export commodities. RVS is newly

Analysis of the dynamic forces acting on a vibrating screen

Among the main components of the set, we can highlight the base structure (numbers 01 and 02), which has the function of supporting the vibrant part. The main part of the set,

Simulation of particle flow on an elliptical vibrating screen

The vibrating screen is one of the most general pieces of equipment in the separation of granular materials based on size. According to the movement trace, screens can be

Characteristics and efficiency of a new vibrating screen

According to vibration trace, linear vibrating screens, circular vibrating screens, and elliptical vibrating screens are commonly used. These motions follow the same paths everywhere

Numerical simulation of particle screening efficiency of

With the increasing requirements for energy conservation and environmental protection, multi-layer vibrating screens have become hot issues. Compared with single-layer

Screening efficiency and screen length of a linear vibrating

The effect of screen length on the screening efficiency of particles is studied under various single parameter conditions including frequency, amplitude, vibration angle, and screen

Vibrating screen SKF

Vibrating screen designs generally use labyrinth seals to protect the rolling bearings. With this type of seal, it is important to maintain a sufficient quantity of grease in the labyrinth

Vibratory Screens General Kinematics

GK Home > Vibratory Screens A leader in separation technology, General Kinematics screens can be found worldwide in a large variety of industries. From the separation of

Syntron Material Handling Vibrating Screens

Vibrating Screens. From aggregates to coal, to , processing, pharmaceuticals, and other processes, Syntron® screen feeders are employed to scalp, separate, size, de

Stepwise shape optimization of the surface of a vibrating

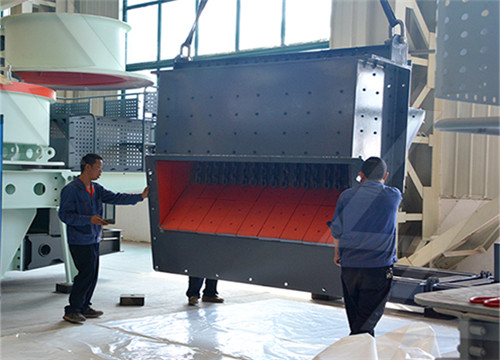

2021年10月1日 The structure of a real vibrating screen is particularly complicated and mainly comprises a screen box, screen mesh, and vibration exciters. A simplified three-dimensional model of the vibrating screen, shown in Fig. 1, is established to reduce the complexity but realize the actual screening effect.Additionally, the sieving process in the

Research on spatial Lissajous trajectory vibrating screen

2019年8月26日 The vibrating screen is a key equipment for separating granular materials based on size and is often used extensively in mining, building, agriculture, metallurgy, drilling, and other industries. 1 The vibrating trajectory is the most important factor of a vibrating screen. So researchers never stop to explore the appropriate trajectories of

Vibrating screen SKF

2023年2月23日 Vibrating screen. This example shows the bearing selection process applied to an application case in which a vibrating screen manufacturer is selecting the bearings for a new machine. Each step of the example is described in an expandable/drop-down section below. The steps in the example follow the sequence in the bearing

Development and Verification of the Diagnostic Model of

2020年6月18日 The minerals processing enterprises are widely using vibrating machines to separate different fractions of materials. Sieving efficiency is greatly dependent on particle trajectories, or orbit, of periodical motion over the sieving decks. A screening process is very dependable on design parameters such as the vibrator power, synchronisation of their

HEAVY DUTY INCLINED VIBRATING SCREENS Deister

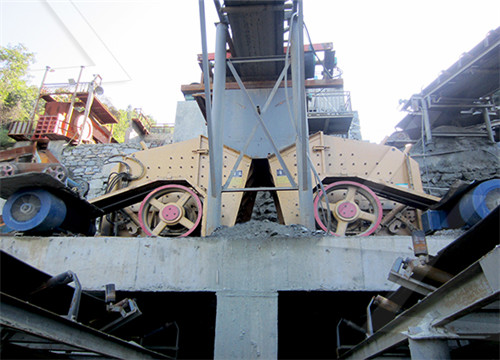

2012年4月12日 vibrating frame and screening surface. Dual vibrating mechanisms are standard on 2 and 3 deck, 8' x 20'; and on 2 deck, 8' x 24' screens. Triple vibrating mechanisms are standard on 3 deck 8' x 24' and larger units. The two shafts of the dual mechanism are each individually motor driven while the triple mechanism is driven on the

Syntron Material Handling Vibrating Screens

1 Vibrating Screens. From aggregates to coal, to , processing, pharmaceuticals, and other processes, Syntron® screen feeders are employed to scalp, separate, size, de-dust, and de-water

Leger Shoot At Vibrating Screen

2021年6月17日 Leger Shoot At Vibrating Screen. A standard round vibratory separator uses a vibrating screen cloth enclosed in frames that are vibrated by a motion generator consisting of a doubleend shaft motor with eccentric weights on the top and bottom of the vertically mounted motor see figure 1 the motor rotates counterclockwise ccw when

Stepwise shape optimization of the surface of a vibrating

2021年10月1日 The structure of a real vibrating screen is particularly complicated and mainly comprises a screen box, screen mesh, and vibration exciters. A simplified three-dimensional model of the vibrating screen, shown in Fig. 1, is established to reduce the complexity but realize the actual screening effect.Additionally, the sieving process in the

Numerical simulation of particle screening efficiency of

2021年11月20日 The research on the physical parameters of the multi-layer vibrating screen is of great significance to the actual production. However, analysis and simulation studies of multi-layer vibrating screens are limited. In this , the screening process of wet particles on a multi-layer vibrating screen was simulated by using the discrete

Development and Verification of the Diagnostic Model of

2020年6月18日 The minerals processing enterprises are widely using vibrating machines to separate different fractions of materials. Sieving efficiency is greatly dependent on particle trajectories, or orbit, of periodical motion over the sieving decks. A screening process is very dependable on design parameters such as the vibrator power, synchronisation of their

Vibrating screen SKF

2023年2月23日 Vibrating screen. This example shows the bearing selection process applied to an application case in which a vibrating screen manufacturer is selecting the bearings for a new machine. Each step of the example is described in an expandable/drop-down section below. The steps in the example follow the sequence in the bearing

Structure of vibrating screen. Download

In this , coal screening in vibrating screen was carried out with the size ranges of −6 mm + 4 mm, −4 mm + 2 mm, and −2 mm + 0.5 mm. The vibrating screen was newly designed with

Syntron Material Handling Vibrating Screens

1 Vibrating Screens. From aggregates to coal, to , processing, pharmaceuticals, and other processes, Syntron® screen feeders are employed to scalp, separate, size, de-dust, and de-water

HEAVY DUTY INCLINED VIBRATING SCREENS Deister

2012年4月12日 vibrating frame and screening surface. Dual vibrating mechanisms are standard on 2 and 3 deck, 8' x 20'; and on 2 deck, 8' x 24' screens. Triple vibrating mechanisms are standard on 3 deck 8' x 24' and larger units. The two shafts of the dual mechanism are each individually motor driven while the triple mechanism is driven on the

second crusher japan-used jaw crushers for sale in jordan

كسارة متنقلة للبيع أو الإيجار

stone crusher plant malaysia sri lanka price

بيع آلة المحجر ومعمل كسارة في النرويج

machine used to grind stone for gold

daftar harga mesin محطم

المعدات والرمل صنع pengsui

industrial cement production line introduction

تكلفة استخراج الرصاص من خام

crushing and screening plant limestone crusher

crush a can-Crush a Can in 13 Seconds

رقم اتصال سبهاش سوداجار من مطحنة ريموند

عملية صنع الاسمنت

كسارة الصخور المتنقلة كسارة الفك

قیمت ماشین آلات safido

top 10 best of construction machinery mobile concrete mixer plant

مصنعي الكسارة الصغيرة في إنجلترا

أسعار المعادن الخردة التيتانيوم لكل ز في المملكة المتحدة

stone types mdash granite marble reconstituted stone limestone

marble quarry africa

stone crushing desighn machines

تلعب مصنع كسارة في المملكة العربية السعودية

penjual mesin crusher iron ore jakarta

nickel mine simulation free games

بيع بيع كسارة صغيرة متنقلة

Sodium Sulfate Comprising

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20