الحار منتجات

ملكنا الإخبارية

hammer mill size reduction machine-Hammer mill by SaraswathiB

Hammer mills Andritz

Multimill hammer mill series. The Multimill series consists of fine-grinding hammer mills. The Multimill is designed with small hammer-to-screen clearance that secures minimum

进一步探索Used Hammer Mills for sale. Fitzpatrick equipmentmore Used Hammer Mills For Sale Federal Equipment CompanyFEED AND BIOFUEL HAMMER MILL ANDRITZ GROUPHammer mills ANDRITZUsed Hammer Mills BuySell Used Mills Aaron Equipment根据热度为您推荐•反馈

Hammer Mills for Particle Size Reduction

FEECO hammer mills utilize a central rotating shaft, fitted with several “hammers” affixed to pivots on the shaft. As the shaft spins, the

预计阅读时间:5 分钟

Design and Analysis of a Hammer Mill Machine in High

This stone proposes a three-dimensional model of the hammer mill for high-efficacy recycle process. It has been established with modeling software (SolidWorks) to solve the

Hammer Mill HM 200: For LaboratoryPilot Plant :: RETSCH

Hammer Mill HM 200 Rugged design meets high final fineness. Hammer mills are used for crushing, pulverizing and deagglomeration of medium-hard, hard, brittle, tough and

Applications: coarse and pre-crushing, desagglomeration

Hammer Mills for Material Reduction Williams

The Traveling Breaker Plate Mill is a non-clog hammer mill. This engineering allows a Slugger Crusher to reduce rock, clay, shale, and bauxite to less than ¾”. It can reduce wet, sticky materials to a size suitable for further

Hammer mill for size reduction Herbold Meckesheim

Machines for crushing, grinding, washing and agglomeration. Shredding equipment: Granulators and mills. Hammer mill for size reduction. We can supply hammer mills for

Hammer Mills and Material Size Reduction Equipment

Important features of Prater Full-Screen Hammer Mills include: Durable, heavy-duty fabrication designed for superior operation and long lifespan. 100% of screen utilized for

Hammer Mill Machine: The Definitive Buying Guide for

2023年3月2日 A hammer mill machine refers to a crusher that can grind, crush and pulverize various types of ingredients or materials. Crushing ginger. Ordinarily, hammer

All you need to know about The Hammer Mill Machine

2022年3月24日 Schematic diagram of hammer mill machine. The hammer mill consists of . 1. Feed Chute. Material is fed into the machine through a feed chute. 2. Discharge chute.

Effect of screen size on particle size distribution and

2022年4月1日 The diameters of the pulleys driving the size reduction machine were obtained from the speed ratio between the hammer mill and the prime mover: (9) D p, m i l l = D p, m o t o r (1 − s) N m o t o r N m i l l where N m o t o r is the rotational speed of the electric motor (rpm) and N m i l l is the rotational speed of the mill (rpm).

Hammer Milling Hammer Mills AVEKA

Hammer milling parameters such as screen size, blade selection and rotor speed can be optimized for each application, depending on the equipment used. The typical particle sizes that can be achieved with hammer mills

Hammer Mill HM 200: For LaboratoryPilot Plant :: RETSCH

Hammer Mill HM 200 Rugged design meets high final fineness. Hammer mills are used for crushing, pulverizing and deagglomeration of medium-hard, hard, brittle, tough and fibrous samples. The rugged RETSCH Hammer Mill HM 200 accepts large feed sizes up to 100 mm which can be reduced to less than 0.8 mm, depending on the sample properties.

Energies Free Full-Text Comparison of Pin Mill and

Dried sphagnum moss was ground using a pin mill and a hammer mill under various operating conditions, i.e., changes in the rotor frequency and feed rate. The specific energy consumption of the size reduction was recorded. The ground powder was characterized by median particle size, width of size distribution (span), loose and tapped bulk densities,

Art of Grinding-Particle size reduction Benison Media

2018年7月23日 There are two types of machines used for particle size reduction-Hammer mill and Roller mill. Most of the feed mills uses hammer mills. Particularly, aqua feed manufacturing plants uses roller mill after hammer mill to achieve fine grinding. In Hammer mill, set of moving high speed hammers breaks the grains which comes in contact by

Hammer Mills: Working Principle, Types and Application

2022年11月24日 This type of hammer mill is well-suited for lighter materials like , green, biomass, etc. Gravity Discharge Industrial Hammer Mills: This hammer mill makes use of swinging hammers, mounted on a shaft. The process of particle size reduction takes place by the hammering application, plus via the particle-on-particle force.

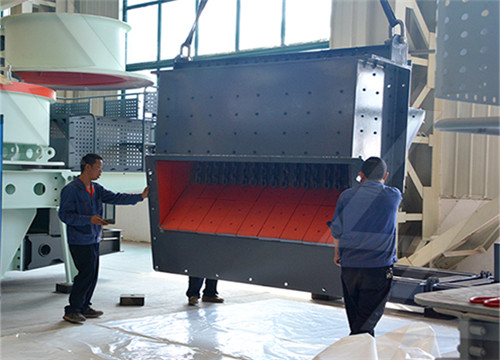

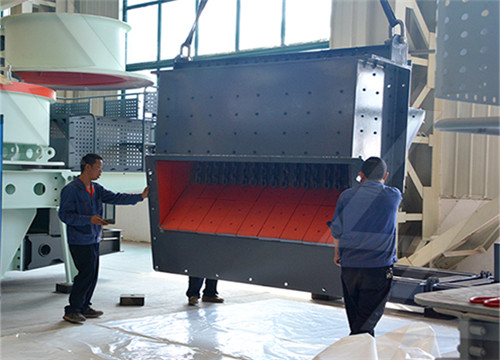

Hammer Mill Machine Wood Machinery Equipment Co., Ltd

2023年2月28日 The structure and working principle of the hammer crusher. Structure: The hammer mill is currently the most widely used type of mill, with a relatively high volume of electrical products and good versatility.Its structure consists of three parts: feed inlet, crushing chamber (rotor, hammer, screen, tooth plate), and discharge part (fan,

Corn Grinder Mazie Milling Machine Hammer Mill

Corn Grinder Mazie Milling Machine Hammer Mill Machine For Animals Feed,Find Complete Details about Corn Grinder Mazie Milling Machine Hammer Mill Machine For Animals Feed,Corn Grinder Mazie Milling Machine Flour Mill,Hammer Mill Machine For Animals Feed,Mini Flour Mill Price In Pakistan from Supplier or Manufacturer-Henan

Hammer Mill Crushers Industrial Hammer Mill Crusher

A hammer mill is a rock crusher that employs a rain of hammer blows to shatter and disintegrate a variety of materials. Hammer mills produce a finished product size that is dependent upon the following criteria: Openings in perforated screens or grate bars. Number, size, and type of hammers. Grinding plate setting.

Industrial Hammer Mills and Pulverizing

Industrial hammer mills are designed to crush a comprehensive variety of solid materials ranging from soft to hard for size reduction needs from 6mm to 35 microns for optimal particle size distribution for a variety of milling

Energy consumption of two-stage fine grinding of

2018年3月12日 The Rittinger constant of 104.5 for the rotor impact mill grinding is larger than 58.6 for the hammer mill grinding (Fig. 5), indicating that the hammer mill used less energy than the rotor impact mill for similar size reduction. However, it should be noted that they were not operated in the similar grinding regime; the rotor impact mill had a

Particle size reduction by a hammer mill I: Effect of output

A hammer mill is an impact mill commonly used in pharmaceutical manufacturing for reducing particle size for a variety of drugs. Commercial grade ammonium sulfate was milled as a model powder. This salt was sieved to obtain particle size fractions with average diameters of 1.3, 0.9, and 0.72 mm which were used as feed particles.

[PDF]

EXPERIMENT AND MODEL-BASED INVESTIGATION OF

2014年12月1日 cal forces using grinding equipment. The most commonly used mills are the rotary cutter, hammer mill, roller mill, ball mills and fl uid energy mills, used in various stages of manufacturing. Size reduction is generally achieved by particle fracturing and subsequent fragmentation under the action of externally applied energy.

Hammermills and Roller Mills Engormix

2020年7月17日 Hammermills accomplish size reduction by impacting a slow moving target, such as a cereal grain, with a rapidly moving hammer. The target has little or no momentum (low kinetic energy), whereas the hammer tip is travelling at a minimum of 16,000 feet per minute (4,880 m/min) and perhaps in excess of 23,000 feet per minute (7,015 m/min)

Milling for Tablet Making Outsourcing-pharma

2020年8月3日 Product toughness and resistance determine the best mill for a given application. The size-reduction method using these milling technologies is categorized by the amount of energy ––or shear force –– imparted on the ingredients (sorting the technologies from low shear to high shear: screeners and sieves, oscillators, conical, and hammer

Hammer mill, Hammer pulverizer All industrial

The hammer mill has a strong, thick-walled drum. As product is fed into the machine, hammers mounted on a rotor spin within at high speed, grinding and crushing it against a sieve to produce particles of a desired size. Applications. The hammer mill is used primarily in industrial settings. It can provide a reduction ratio of as much as 20:1.

Particle Size Reduction Pharma Notes

2021年3月16日 Mechanism of size reduction Impact this involve hammer or bar at high speed (hammer mill). Particle Size 50-8,000 µm. Compression- particle crushed b/w rollers by the application of force (roller mill). Particle Size 50-10,000 µm. Cutting the material cut by a sharp blade (cutter mill), Particle Size 100-80,000 µm.

Art of Grinding-Particle size reduction Benison Media

2018年7月23日 There are two types of machines used for particle size reduction-Hammer mill and Roller mill. Most of the feed mills uses hammer mills. Particularly, aqua feed manufacturing plants uses roller mill after hammer mill to achieve fine grinding. In Hammer mill, set of moving high speed hammers breaks the grains which comes in contact by

Hammer mill For sale small hammer mill

Consider the Taichang hammer mill’s many features as you do so. 1. Versatile: This diverse and versatile machine can handle biomass materials of all types and sizes, including crop stalks, chips, tree branches,

Corn Grinder Mazie Milling Machine Hammer Mill

Corn Grinder Mazie Milling Machine Hammer Mill Machine For Animals Feed,Find Complete Details about Corn Grinder Mazie Milling Machine Hammer Mill Machine For Animals Feed,Corn Grinder Mazie Milling Machine Flour Mill,Hammer Mill Machine For Animals Feed,Mini Flour Mill Price In Pakistan from Supplier or Manufacturer-Henan

Hammer Mills for Particle Size Reduction

FEECO hammer mills utilize a central rotating shaft, fitted with several “hammers” affixed to pivots on the shaft. As the shaft spins, the

Design and Analysis of a Hammer Mill Machine in High

This stone proposes a three-dimensional model of the hammer mill for high-efficacy recycle process. It has been established with modeling software (SolidWorks) to solve the

Hammer Mill HM 200: For LaboratoryPilot Plant :: RETSCH

Hammer Mill HM 200 Rugged design meets high final fineness. Hammer mills are used for crushing, pulverizing and deagglomeration of medium-hard, hard, brittle, tough and

Hammer Mills for Material Reduction Williams

The Traveling Breaker Plate Mill is a non-clog hammer mill. This engineering allows a Slugger Crusher to reduce rock, clay, shale, and bauxite to less than ¾”. It can reduce wet, sticky materials to a size suitable for further

Hammer mill for size reduction Herbold Meckesheim

Machines for crushing, grinding, washing and agglomeration. Shredding equipment: Granulators and mills. Hammer mill for size reduction. We can supply hammer mills for

Hammer Mills and Material Size Reduction Equipment

Important features of Prater Full-Screen Hammer Mills include: Durable, heavy-duty fabrication designed for superior operation and long lifespan. 100% of screen utilized for

Hammer Mill Machine: The Definitive Buying Guide for

2023年3月2日 A hammer mill machine refers to a crusher that can grind, crush and pulverize various types of ingredients or materials. Crushing ginger. Ordinarily, hammer

All you need to know about The Hammer Mill Machine

2022年3月24日 Schematic diagram of hammer mill machine. The hammer mill consists of . 1. Feed Chute. Material is fed into the machine through a feed chute. 2. Discharge chute.

Effect of screen size on particle size distribution and

2022年4月1日 The diameters of the pulleys driving the size reduction machine were obtained from the speed ratio between the hammer mill and the prime mover: (9) D p, m i l l = D p, m o t o r (1 − s) N m o t o r N m i l l where N m o t o r is the rotational speed of the electric motor (rpm) and N m i l l is the rotational speed of the mill (rpm).

Hammer Milling Hammer Mills AVEKA

Hammer milling parameters such as screen size, blade selection and rotor speed can be optimized for each application, depending on the equipment used. The typical particle sizes that can be achieved with hammer mills

Hammer Mill HM 200: For LaboratoryPilot Plant :: RETSCH

Hammer Mill HM 200 Rugged design meets high final fineness. Hammer mills are used for crushing, pulverizing and deagglomeration of medium-hard, hard, brittle, tough and fibrous samples. The rugged RETSCH Hammer Mill HM 200 accepts large feed sizes up to 100 mm which can be reduced to less than 0.8 mm, depending on the sample properties.

Energies Free Full-Text Comparison of Pin Mill and

Dried sphagnum moss was ground using a pin mill and a hammer mill under various operating conditions, i.e., changes in the rotor frequency and feed rate. The specific energy consumption of the size reduction was recorded. The ground powder was characterized by median particle size, width of size distribution (span), loose and tapped bulk densities,

Art of Grinding-Particle size reduction Benison Media

2018年7月23日 There are two types of machines used for particle size reduction-Hammer mill and Roller mill. Most of the feed mills uses hammer mills. Particularly, aqua feed manufacturing plants uses roller mill after hammer mill to achieve fine grinding. In Hammer mill, set of moving high speed hammers breaks the grains which comes in contact by

Hammer Mills: Working Principle, Types and Application

2022年11月24日 This type of hammer mill is well-suited for lighter materials like , green, biomass, etc. Gravity Discharge Industrial Hammer Mills: This hammer mill makes use of swinging hammers, mounted on a shaft. The process of particle size reduction takes place by the hammering application, plus via the particle-on-particle force.

Hammer Mill Machine Wood Machinery Equipment Co., Ltd

2023年2月28日 The structure and working principle of the hammer crusher. Structure: The hammer mill is currently the most widely used type of mill, with a relatively high volume of electrical products and good versatility.Its structure consists of three parts: feed inlet, crushing chamber (rotor, hammer, screen, tooth plate), and discharge part (fan,

Corn Grinder Mazie Milling Machine Hammer Mill

Corn Grinder Mazie Milling Machine Hammer Mill Machine For Animals Feed,Find Complete Details about Corn Grinder Mazie Milling Machine Hammer Mill Machine For Animals Feed,Corn Grinder Mazie Milling Machine Flour Mill,Hammer Mill Machine For Animals Feed,Mini Flour Mill Price In Pakistan from Supplier or Manufacturer-Henan

Hammer Mill Crushers Industrial Hammer Mill Crusher

A hammer mill is a rock crusher that employs a rain of hammer blows to shatter and disintegrate a variety of materials. Hammer mills produce a finished product size that is dependent upon the following criteria: Openings in perforated screens or grate bars. Number, size, and type of hammers. Grinding plate setting.

Industrial Hammer Mills and Pulverizing

Industrial hammer mills are designed to crush a comprehensive variety of solid materials ranging from soft to hard for size reduction needs from 6mm to 35 microns for optimal particle size distribution for a variety of milling

Energy consumption of two-stage fine grinding of

2018年3月12日 The Rittinger constant of 104.5 for the rotor impact mill grinding is larger than 58.6 for the hammer mill grinding (Fig. 5), indicating that the hammer mill used less energy than the rotor impact mill for similar size reduction. However, it should be noted that they were not operated in the similar grinding regime; the rotor impact mill had a

Particle size reduction by a hammer mill I: Effect of output

A hammer mill is an impact mill commonly used in pharmaceutical manufacturing for reducing particle size for a variety of drugs. Commercial grade ammonium sulfate was milled as a model powder. This salt was sieved to obtain particle size fractions with average diameters of 1.3, 0.9, and 0.72 mm which were used as feed particles.

EXPERIMENT AND MODEL-BASED INVESTIGATION OF

2014年12月1日 cal forces using grinding equipment. The most commonly used mills are the rotary cutter, hammer mill, roller mill, ball mills and fl uid energy mills, used in various stages of manufacturing. Size reduction is generally achieved by particle fracturing and subsequent fragmentation under the action of externally applied energy.

Hammermills and Roller Mills Engormix

2020年7月17日 Hammermills accomplish size reduction by impacting a slow moving target, such as a cereal grain, with a rapidly moving hammer. The target has little or no momentum (low kinetic energy), whereas the hammer tip is travelling at a minimum of 16,000 feet per minute (4,880 m/min) and perhaps in excess of 23,000 feet per minute (7,015 m/min)

Milling for Tablet Making Outsourcing-pharma

2020年8月3日 Product toughness and resistance determine the best mill for a given application. The size-reduction method using these milling technologies is categorized by the amount of energy ––or shear force –– imparted on the ingredients (sorting the technologies from low shear to high shear: screeners and sieves, oscillators, conical, and hammer

Hammer mill, Hammer pulverizer All industrial

The hammer mill has a strong, thick-walled drum. As product is fed into the machine, hammers mounted on a rotor spin within at high speed, grinding and crushing it against a sieve to produce particles of a desired size. Applications. The hammer mill is used primarily in industrial settings. It can provide a reduction ratio of as much as 20:1.

Particle Size Reduction Pharma Notes

2021年3月16日 Mechanism of size reduction Impact this involve hammer or bar at high speed (hammer mill). Particle Size 50-8,000 µm. Compression- particle crushed b/w rollers by the application of force (roller mill). Particle Size 50-10,000 µm. Cutting the material cut by a sharp blade (cutter mill), Particle Size 100-80,000 µm.

Art of Grinding-Particle size reduction Benison Media

2018年7月23日 There are two types of machines used for particle size reduction-Hammer mill and Roller mill. Most of the feed mills uses hammer mills. Particularly, aqua feed manufacturing plants uses roller mill after hammer mill to achieve fine grinding. In Hammer mill, set of moving high speed hammers breaks the grains which comes in contact by

Hammer mill For sale small hammer mill

Consider the Taichang hammer mill’s many features as you do so. 1. Versatile: This diverse and versatile machine can handle biomass materials of all types and sizes, including crop stalks, chips, tree branches,

Corn Grinder Mazie Milling Machine Hammer Mill

Corn Grinder Mazie Milling Machine Hammer Mill Machine For Animals Feed,Find Complete Details about Corn Grinder Mazie Milling Machine Hammer Mill Machine For Animals Feed,Corn Grinder Mazie Milling Machine Flour Mill,Hammer Mill Machine For Animals Feed,Mini Flour Mill Price In Pakistan from Supplier or Manufacturer-Henan

دراسات حول صناعة التعدين المحجر

آلات تكسير العقيق

concrete crusher producers europe-crusher producers in europe

cheap crusher machine nepal

المورد من كسارة مخروط-سنة الصنع من كسارة مخروط

مناجم الذهب في شرق جمهورية الكونغو الديمقراطية

مكابس جلاية كسارة

HD圆锥破-诺德伯格系列圆锥破碎机

سنگ شکن بتن آلوده آب زمین

سيور ناقلة مناجم مفتوحة من سريلانكا بسعر البيع

干粉砂浆成套设备那里有的卖-365体育直营 【澳門日報】

مشروع تعدين الذهب والنحاس-طرق النحاس تعدين الذهب

مصنعي الكسارات الاجمالية في البرازيل

specification china cone crusher-Hydraulic Cone crusher

limestone crusher china

crusher 2 80 mm-Cone Crushers HP Series Cone Crushers

در آفریقا آسیاب مهره

سنگ شکن بتن از اتریش

كسارات من مناسبة للحجارة فخ

عملية مطحنة الضغط العالي

ceramic grinding choose jun

jual crusher kapasitas ton jam crusher للبيع

سنگ شکن اس ام اس

تصميم شلال للفحم

stone crushing machine manufacturers in china-Guangzhou Yonran Stone Crusher Machinery

granite granite mining plant and machinery

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20