الحار منتجات

ملكنا الإخبارية

how to ball mill works for clinker grinding model

Matrix model of the grinding process of cement clinker in

2018年2月1日 It is shown that the most complete and informative characterization of the grinding process in a ball mill is a grinding matrix taking into account the transformation

Clinker size and cement grinding GCP Applied Technologies

2021年2月8日 For ball mills, it is more efficient to reduce the size of large particles prior to the mill, using physical means such as a hammer crusher, pre-grinder, or a roll press.

Ball Mill an overview ScienceDirect Topics

Quantum Nanostructures (QDs): An Overview. D. Sumanth Kumar, H.M. Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3.6.1.1 Ball Milling. A ball mill is a type of

CLINKER GRINDING IN CEMENT PRODUCTION

2019年2月21日 Earlier we considered a mixture of which materials is used in cement production. The base of this mixture is a clinker. In this article, we will consider the

how to ball mill works for clinker grinding model

Standard Bond Ball Mill Grindability Test Method-Procedure. 2015-12-14 The Wi value from this equation should conform with the motor output power to an average overflow

how to ball mill works for clinker grinding model

2018-2-1 Matrix model of the grinding process of cement clinker in the ball mill. Sharapov, Rashid R. Abstract. In the article attention is paid to improving the efficiency of

how to ball mill works for clinker grinding model

Feb 01, 2018Matrix model of the grinding process of cement clinker in the ball mill Sharapov, Rashid R Abstract In the article attention is paid to improving the efficiency of production

How To Ball Mill Works For Clinker Grinding Model

Used Ball Mill For Clinker Grinding 130th. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics

how to ball mill works for clinker grinding model

The "work horse" of the cement grinding plant is the two-compartment ball mill, commonly called the tube mill. Significant advances in model development were achieved in recent

How To Ball Mill Works For Clinker Grinding Model

2021年11月29日 How To Ball Mill Works For Clinker Grinding Model; Ball Mills Psp Eng. 3D model of a raw mill Raw mill 5.4 x 11 m with a pre-drying chamber Example of a ow

(PDF) Predictive Controller Design for a Cement Ball Mill

2020年9月15日 Predictive Controller Design for a Cement Ball Mill Grinding Process under Larger Heterogeneities in Clinker Using State-Space Models September 2020 DOI: 10.3390/designs

Mutual compatibility of superplasticizers (PC, SNF),

Cements were ground in a laboratory ball mill to a specific surface area of 4000 cm 2 /g (acc. Blaine). The amount of material in the mill was 6 kg and the diameter of the grinding media was in the range of 15–40 mm. Clinkers were mixed with gypsum as a source of calcium sulfate (2% for the CL clinker and 4% for the CH clinker) and with

CLINKER GRINDING IN CEMENT PRODUCTION

2019年2月21日 Earlier we considered a mixture of which materials is used in cement production. The base of this mixture is a clinker. In this article, we will consider the composition of clinker and its impact on grinding balls deterioration in milling process. Clinker (in cement industry) is transitional product in cement production. Upon heating

Ball Mill Explained saVRee

If a ball mill uses little or no water during grinding, it is a ‘dry’ mill. If a ball mill uses water during grinding, it is a ‘wet’ mill. A typical ball mill will have a drum length that is 1 or 1.5 times the drum diameter. Ball mills with a drum length to diameter ratio greater than 1.5 are referred to as tube mills. Ball mills may be

Use Cement Ball Mill Grinding Cement Clinker Cement

According to the needs of different customers, there are two types of cement ball mill: open-flow mill and circular-flow mill. The φ3.8×13 cement ball mill with double-sliding structure solves the problem of the similar product “the discharge end slide bearing temperature is too high to operate continuously”, which ensures the equipment can run continuously and

[PDF] A quick method for Bond work index approximate

2016年11月1日 The Bond work index is a measure of ore resistance to crushing and grinding and is determined using the Bond grindability test. Its value constitutes ore characteristic and is used for industrial comminution plants designing. Determining the Bond work index value is quite complicated, timeconsuming and requires trained operating

how to ball mill works for clinker grinding model

Feb 01, 2018Matrix model of the grinding process of cement clinker in the ball mill Sharapov, Rashid R Abstract In the article attention is paid to improving the efficiency of production of fine powders, in particular Portland cement clinker The questions of Portland cement clinker grinding in closed circuit ball mills. Cited by: 1

how to ball mill works for clinker grinding model

2018-2-1 Matrix model of the grinding process of cement clinker in the ball mill. Sharapov, Rashid R. Abstract. In the article attention is paid to improving the efficiency of production of fine powders, in particular Portland cement clinker. The questions of Portland cement clinker grinding in . Capacity. T/H. Reviews

how to ball mill works for clinker grinding model

The "work horse" of the cement grinding plant is the two-compartment ball mill, commonly called the tube mill. Significant advances in model development were achieved in recent years (Benzer et al, 2001, 2003) through research on industrial scale.

Mutual compatibility of superplasticizers (PC, SNF),

Cements were ground in a laboratory ball mill to a specific surface area of 4000 cm 2 /g (acc. Blaine). The amount of material in the mill was 6 kg and the diameter of the grinding media was in the range of 15–40 mm. Clinkers were mixed with gypsum as a source of calcium sulfate (2% for the CL clinker and 4% for the CH clinker) and with

Breakthrough in Clinker Grinding Massachusetts

2012年11月8日 grinding seeks to reduce materials from roughly one meter cubes of blasted stone to a size where at least 80 percent of the raw material is less than 75 microns. Finish grinding of clinker and other cement ingredients reduces 25 mm clinker balls to particle sizes optimally ranging from 3 to 30 microns. The

How To Ball Mill Works For Clinker Grinding Model

2021年11月29日 How To Ball Mill Works For Clinker Grinding Model; Ball Mills Psp Eng. 3D model of a raw mill Raw mill 5.4 x 11 m with a pre-drying chamber Example of a ow sheet of raw mill grinding circuit 2 4 6 8 1 ball mill 2 elevator 3 separator VTP 4 separating cyclone 5 mill fan 6 separator fan 7 clinker bin material 8 gypsum bin

What are the parts of a mill in a cement plant? LinkedIn

2023年3月6日 The parts of a cement mill include: Grinding Media: These are the balls or cylinders that are used to grind the raw materials in the mill. Mill Shell: This is the outermost layer of the mill

how to ball mill works for clinker grinding model

how to ball mill works for clinker grinding model . Matrix model of the grinding process of cement clinker inBall mills for fine grinding cement clinker and additives are widely used around the world To improve t.Our crushers are designed and built with advanced technology and stringent quality control at every stage of the manufacturing process, to

TRX Gold Corporation says 1,000 tonne per day capacity

8 小时之 The mill will have dimensions of 3,200 millimetres (mm) diameter by 4,500 mm equivalent grinding length and a 630 kW drive motor. The ball mill is the long-lead critical item and is scheduled to be shipped within 60 days, ex-works.

(PDF) Modeling and simulation of vertical roller mill using

2023年3月3日 PDF There are few studies concerning the process simulation of vertical roller mills (VRMs). In this research work, the application of population Find, read and cite all the research you

[PDF] A quick method for Bond work index approximate

2016年11月1日 The Bond work index is a measure of ore resistance to crushing and grinding and is determined using the Bond grindability test. Its value constitutes ore characteristic and is used for industrial comminution plants designing. Determining the Bond work index value is quite complicated, timeconsuming and requires trained operating

Iron Ore Powder Dressing Grinding Ball Mill Plant Alibaba

Iron Ore Powder Dressing Grinding Ball Mill Plant,Find Complete Details about Iron Ore Powder Dressing Grinding Ball Mill Plant,Iron Ore Powder Ball Mill,Dressing Ball Mill,Ball Mill Plant from Supplier or Manufacturer-Henan Hongji Mine Machinery Co., Ltd.

How To Ball Mill Works For Clinker Grinding Model

Used Ball Mill For Clinker Grinding 130th. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.It works on the principle of impact and attrition size reduction is done by impact asused ball mill for clinker grinding tph GBMused

鄂式碎石机

mining mobile crusher wiring diagram

DXN china stone crsher

كسارة كسارة متنقلة pex250 750jaw كسارة

gypsum crusher shanghai-china Manufacturer gypsum mineral crusher

حجر العقيق الطبيعي للجدران والأرضيات

موردي مطحنة الكرات

blanchard grinding machine manufacturing

أعلى 5 ماركات من كسارات الحجر

صور ذهب يخرج مني

crushing plant 250t h prices

القضية 580m كسارة الصخور المرفقة

تكلفة آلات صنع الرمل الاصطناعي

المغزل العمودي أسعار الفحم مطحنة

طحن حجر u0026 عصا

mj 520 high output mini mill for grain

أفضل مصنع تكسير الصخور للجرانيت

keene g force rock crusher youtube-Youtube Video Mobile Rock Crusher

مصنعي الكرة مطحنة الصين التعدين

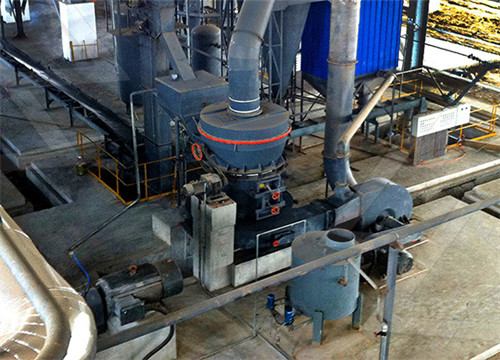

working principle of cement mill

معدات التعدين كسارة الفك

معدات تركيز الجاذبية الذهبية الجاذبية الذهبية

ultrafine grinding mill tongkat

horizontal sand electrical

المورد كسارة الصخور مصر

عملية تكسير آلات رمل الصخور الصخرية

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20