الحار منتجات

ملكنا الإخبارية

iron ore flotation process diagram

Flotation of Iron Ores: A Review: Mineral Processing and

2019年11月19日 ABSTRACT. A tremendous amount of research has been done on refining the flotation process for iron ore and designing the reagents which go into it. This

Flotation of Iron Ore: A Brief Review MDPI

2020年8月3日 The amount of high grade and easy-to-process iron ores are in continual decline and beneficiation popular anionic collectors used in iron ore flotation practice

(PDF) Flotation of Iron Ores: A Review ResearchGate

2019年11月19日 Overview of the beneficiation process used by the Yuanjiacun iron ore concentrator, utilizing anionic reverse flotation (based on Chen, Ge and Yu 2005; Mao,

Flotation Process an overview ScienceDirect Topics

The flotation process depends on several design and operation First, the collector is added to the iron ore slurry to selectively coat the iron oxide particles, making the surface

Iron ore flotation: Practice, problems, and prospects

2014年1月8日 The significant applications of iron ore flotation are reviewed along with an abbreviated discussion on theory and reagent use. Problems or conditions which have

Froth Flotation of Iron Ores Pdfs.semanticscholar

2018年12月18日 the most popular flotation route in iron ore industry, the direct flotation of iron ox ides still appears desirable for some low grade iron ores that contain a vast

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

Energy and Environmental Profile of the U.S. Mining

2013年11月8日 4.1 Process Overview 4.1.1 Iron Ore Mining There are two basic methods of mining iron ore. These are: • Surface mining or open-pit mining chemical

Particle size distribution of iron ore tailings

Froth flotation has been widely used in upgrading iron ores. Iron ore flotation can be performed in two technical routes: direct flotation of iron oxides and reverse flotation of gangue minerals

Mineral Processing Flowsheets

2016年3月8日 The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which incorporate

Flotation of Iron Ore: A Brief Review MDPI

2020年8月3日 The amount of high grade and easy-to-process iron ores are in continual decline and beneficiation popular anionic collectors used in iron ore flotation practice are oleic acid and its soaps [16,26]. The Species distribution diagram of oleate as a function of pH (total concentration =1 102 mol/L) (after [29]).

Flotation Process an overview ScienceDirect Topics

The flotation process depends on several design and operation First, the collector is added to the iron ore slurry to selectively coat the iron oxide particles, making the surface hydrophobic. The slurry then goes to a flotation cell, where air bubbles are generated using an Figure 7-104 presents a diagram of a DAF system,

Froth flotation process and its application Wiley Online

2021年2月5日 The sulfide ore flotation process can be studied by both chemical and electrochemical phenomena considering the interfacial energies. A broad application of this process in industrial field is the flotation of iron ores which is of two types: direct and reverse flotation. The later one

Froth Flotation of Iron Ores

2012年1月2日 With the depleting reserves of high-grade iron ore in the world, froth flotation has become increasingly important to process intermediate- and low-grade iron ore in an attempt to meet the rapidly growing demand on the international market. In over half a century’s practice in the iron ore industry, froth flotation has been established as an

Critical importance of pH and collector type on the

2021年2月4日 Collector type and pulp pH play an important role in the lead–zinc ore flotation process. In the current study, the effect of pulp pH and the collector type parameters on the galena and

11.27 Feldspar Processing US EPA

2015年9月10日 A froth flotation process is used for most feldspar ore beneficiation. Figure 11.27-1 shows a process flow diagram of the flotation process. The ore is crushed by primary and secondary crushers and ground by jaw crushers, cone crushers, and rod mills until it is reduced to less than 841 µm (20 mesh). Then the ore passes to a three-stage,

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

CORE Aggregating the world’s open access research

2020年5月6日 CORE Aggregating the world’s open access research s

Iron ore mining and dressing tec-science

2018年6月21日 This means that the mined iron ores need to be specially processed in advance before the blast furnace process. Regions in which iron ore has formed over millions of years (e.g. through volcanism) and can be mined economically are also referred to as iron ore deposits. Especially many ore deposits can be found in countries such as

ru/eand ploration mining iron ore В Малайзии.md at main

Contribute to kokiulinjsb/ru development by creating an account on GitHub.

Iron ore flotation: Practice, problems, and prospects

2014年1月8日 The significant applications of iron ore flotation are reviewed along with an abbreviated discussion on theory and reagent use. Problems or conditions which have militated against a widespread adoption of the flotation process by the iron ore industry, are discussed in contextual relationship to supply, economics, alternatives, and process

Froth Flotation of Iron Ores

2012年1月2日 With the depleting reserves of high-grade iron ore in the world, froth flotation has become increasingly important to process intermediate- and low-grade iron ore in an attempt to meet the rapidly growing demand on the international market. In over half a century’s practice in the iron ore industry, froth flotation has been established as an

11.23 Taconite Ore Processing US EPA

2015年9月10日 11.23.2 Process Description2-5,41 Processing of taconite consists of crushing and grinding the ore to liberate iron-bearing particles, concentrating the ore by separating the particles from the waste material (gangue), and pelletizing the iron ore concentrate. A simplified flow diagram of these processing steps is shown in Figure 11.23-1.

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Froth Flotation Process Detailed Explanation

2023年3月3日 Froth flotation is an important concentration process that can be used to selectively separate hydrophobic materials from hydrophilic waste gangue. In a more simple context, froth flotation is one of the most

Processes Free Full-Text Recycled Smelter Slags for In

2023年3月6日 Figure 1 shows a general process diagram for ferrous slag production. BF slag is produced at higher temperatures (1450 to 1550 °C) during the reduction processes of iron ore, coke, limestone, and other materials. Steel slags are created when scrap metals are melted in an electric arc furnace (EAF) to make liquid steel .

How to Extract Iron from Hematite: Methods and Plants

2023年2月15日 It is easy to extract iron from this kind of haematite by using gravity separation and magnetic separation. Medium-grained hematite refers to iron ore with an embedded particle size between 0.02 and 2mm. This type of hematite is also relatively easy to select, mainly using gravity separation, magnetic separation and magnetic roasting.

Technical Resource Document: Extraction and

2016年3月27日 U.S. Surface Iron Ore Mines, in Thousand Long Tons, 1988 .. 1-13 Table 1-4. Beneficiation Methods Commonly Associated With Iron Ores and the Percentage of Ore Treated by Each Method, 1990 .. 1-15 Table 1-5. Water Usage of Selected Iron Ore Operations and the Sources of the Water

Lead and Zinc Energy

2013年11月8日 Black sphalerite may contain as much as 18 percent iron. Lead Ore The lead produced from lead ore is a soft, flexible and ductile metal. It is bluish-white, very Flotation is the usual mineral separation or concentration process of choice. In flotation, workers use slurry reagents to float the heavy mineral away from the lighter

small lab hammer stone crusher sri lanka

quartz rock crusher plans

المورد لكسارة الفك

zambia crusher suppliers

مقدمة إلى تحميل معالجة المعادن مجانا

مصنعي كسارات البنتونيت في الفلبين

nature cheap factory granite quarry for sales

كسارة الظريف قوات الدفاع الشعبي-إنتاج النفايات

coal production in nigeria

قدم مكعبة يوميا النمذجة دوار الألومينا فرن-

سحق المخطط فحص تدفق نقل

coffee grinder coffee grinders

جیر جیر منجنچورکان بالاست

Platinum Mining Manufacturer

آلة تبطين المطحنة سبعة محاور

كسارات المحمول شطيرة

بسيطة بسيطة الصخور الصلبة سحق مخطط انسيابي النبات

طرق التعدين المعدنية

hnc rubber roller grinders

Pavri Kyanite Nagpur

كيف تجعل شاشة تهتز

روند mioll توپ

كسارة فكية متنقلة عالية الكفاءة موفرة للطاقة بأفضل الأسعار

مناجم الذهب جينا عنوان زيمبابوي

leading quartz crusher manufacturers in india

آلة المجوف في الإمارات العربية المتحدة

حول لدينا

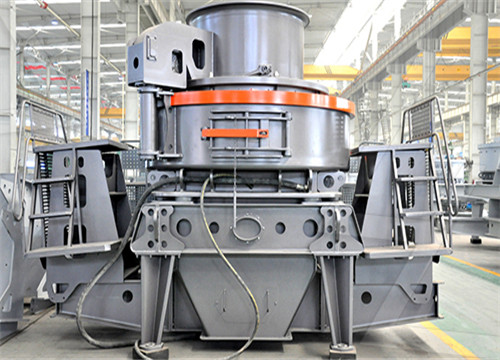

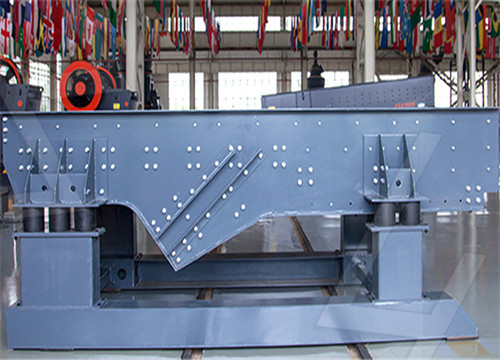

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20