الحار منتجات

ملكنا الإخبارية

2 production process of grinding material-116 Portland Cement Manufacturing

Manufacturing of Portland Cement Process and Materials

What Is Cement Made of?Wet ProcessDry ProcessFor the bulk and continuous manufacturing and production of Portland Cement following mineral materials are used: calcareous materials (limestone or chalk), argillaceous material (shale or clay), blast furnace slag, silica sand, iron ore, and gypsum as raw material.Cement factories are established where these raw materials are available in plenty a...

Manufacture of Portland Cement- Materials and

The manufacture procedures of Portland cement is described below. Mixing of raw material. Burning. Grinding. Storage and packaging. 1. Mixing of

11.6 Portland Cement Manufacturing US EPA

2022年3月22日 cement plants with wet process kilns is 3-05-006, and the six-digit SCC for plants with dry process kilns is 3-05-007. Portland cement accounts for 95 percent of the hydraulic cement production in the United States. The balance of domestic cement production is primarily masonry cement. Both of these materials are produced in portland

Cement Production Process Cement Manufacturing

2020年8月25日 In general, a full cement production process includes the stone crushing, raw mill process, clinker process, and cement grinding process, cement packing process, and related process. The Portland cement manufacturing process is representative of all types of cement. limestone and clay are the main raw materials of cement making, the

Portland Cement Manufacturing Ordinary

Portland Cement Manufacturing Process. Portland cement manufacturing process can be divided into 6 steps: raw material crushing, pre-homogenization, fine grinding, clinker production, cement grinding,

Manufacture Of Portland Cement Process Flow chart

2019年11月30日 Mixing of raw materials: The processes used for the manufacture of portland cement can be classified as dry and wet. In dry process. The raw materials are first reduced in size of about 25mm in crushers and Crushed material is ground to get fine particles into ball mill or tube mill. Each material after screening is stored in a separate

Cement Production and Manufacturing Process Portland

Gypsum which controls the settling of cement. The calcareous and argillaceous raw materials are dried, mixed and heated to a high temperature (around 1000 0 C) in a furnace. The produced granular form is called clinker. Then it is ground with 4% gypsum to obtain Portland cement. There are two main processes in manufacturing Portland cement.

Cement Manufacturing Process: How the Cement is Made?

2 之 The entire manufacturing process in a modern plant is now controlled through a microprocessor based programmable logic control system to maintain a consistently uniform quality of cement and a high rate of production. The entire operation of the plant is controlled centrally in a single control room and the plant employs minimum of manpower as

I03 cement June 2010 GS-gct IEA-ETSAP

2022年4月11日 Cement Production The manufacture of cement is a two-step process, notably, clinker production and cement grinding. In the first step, the raw materials are fed to the kiln system to produce clinker. Clinker consists of silicates, aluminates and ferrites of calcium obtained from the reduction of calcium, silica, alumina

Manufacture of Portland Cement- Materials and

The manufacture procedures of Portland cement is described below. Mixing of raw material. Burning. Grinding. Storage and packaging. 1. Mixing of raw material. The major raw materials used in the manufacture of cement are

Mutual compatibility of superplasticizers (PC, SNF),

In the production of Portland cement, GA are added in small amounts in the range of 0.01 to 0.1% by weight of cement, according to the EN 197–1 standard. 2.2. Materials and cement preparation. To eliminate the influence of the production process on the properties of cement, in this work, cements were prepared under laboratory conditions

Research Progress of Low-Carbon Cementitious Materials

2023年3月1日 The cement manufacturing process is a highly energy-consuming and emission intensive process. Globally, cement production accounts for 5% to 7% of global anthropogenic CO 2 emissions. Being the world’s largest cement producer [1,2,3], China produces and consumes more than half of the world’s total cement production .

(PDF) THE CEMENT MANUFACTURING PROCESS

THE CEMENT MANUFACTURING PROCESS Prof. Dr Elshafie Ahmed Gad Faculty of Applied Science Chemistry Dept. Portland Cement Portland cement is made by mixing substances containing CaCO3 with substances containing SiO2, Al2O3, Fe2O3 and heating them to a clinker which is subsequently ground to powder and mixed with 2-6 % gypsum

Cement Manufacturing Process: What is Cement

2023年3月2日 Raw Materials of Cement. Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method). 1.

Manufacture Of Portland Cement Process Flow chart

2019年11月30日 Mixing of raw materials: The processes used for the manufacture of portland cement can be classified as dry and wet. In dry process. The raw materials are first reduced in size of about 25mm in crushers and Crushed material is ground to get fine particles into ball mill or tube mill. Each material after screening is stored in a separate

Cement Manufacturing Process Chemical Engineering

2020年9月26日 Cement is a material which is used to bind other materials together. Binding means it has an effect of gluing the substances together due to cohesive and adhesive action and then hardens and sets in order to become permanent. Cement is usually not used on its own; it is mixed with other materials called aggregates to produce

CEMENT MANUFACTURING PROCESS ! TYPES OF

2020年5月18日 TYPES OF CEMENT, FLOW CHART. May 18, 2020 by Anand Kamble. Cement manufacturing process is a reliable bonding material. It is obtained by burning calcareous material (lime) and argillaceous material (clay) and then grinding, types of cement. The cement manufacturing process was first produced by Joseph Aspidin, a

ASSESSMENT OF COMPRESSIVE STRENGTH OF

Ordinary Portland Cement (OPC) is used in all concrete mixes, which produced by Suez Cement Company (Suez city, Egypt). Cement type CEM I 42.5 N was a cement grade used.

Stages of the Portland cement process

This stone reviewed major point sources of CO2 emissions at all stages of cement manufacturing, including (1) raw material preparation (grinding and transportation), (2) clinker production and the

Manufacturing of Portland Cement Process and Materials

2020年4月13日 The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C. During this process, these materials partially fuse to form nodular

Research Progress of Low-Carbon Cementitious Materials

2023年3月1日 The cement manufacturing process is a highly energy-consuming and emission intensive process. Globally, cement production accounts for 5% to 7% of global anthropogenic CO 2 emissions. Being the world’s largest cement producer [1,2,3], China produces and consumes more than half of the world’s total cement production .

Portland Cement Manufacturing Process In Cement Plant

The Portland cement manufacturing is a complex process which can be mainly divided into three parts: raw materials preparation, clinker calcination and cement grinding. Raw materials preparation: after materials are quarried, they need to undergo crushing, blending, grinding and storage four processes to finish the raw materials preparation

Cement Manufacturing Process: What is Cement

2023年3月2日 Raw Materials of Cement. Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method). 1.

Cement manufacturing process: Step-by-step guide CCE

2020年7月20日 Cement manufacturing process in summary. Portland cement is manufactured by heating limestone (calcium carbonate) with other materials (such as clay) to 1,450 °C (2,640 °F) in a kiln, in a process known as calcination that liberates a molecule of carbon dioxide from the calcium carbonate to form calcium oxide, or quicklime.

Manufacture Of Portland Cement Process Flow chart

2019年11月30日 Mixing of raw materials: The processes used for the manufacture of portland cement can be classified as dry and wet. In dry process. The raw materials are first reduced in size of about 25mm in crushers and Crushed material is ground to get fine particles into ball mill or tube mill. Each material after screening is stored in a separate

What is Portland cement process of

The wet process for the manufacturing of Portland cement. In the wet process, limestone is first crushed to smaller fragments. Then, it takes to ball or tube mill where it mixes with clay and finely ground. Then, water adds

Portland Pozzolana Cement Manufacturing Plant PPC

There are two ways to manufacture Portland pozzolana cement: 1) Grinding ordinary Portland clinker along with pozzolanic materials and additional gypsum or calcium sulfate; 2) Grinding OPC clinker and pozzolanic materials separately and then mix them together with gypsum. The 1st way is most used in our portland pozzolana manufacturing cement

beneficiation equipment ball mill

قائمة المعدات اللازمة لبدء تعدين الذهب

مطاحن ريموند بسلاسة

معدات التعدين luvia في جنوب أفريقيا

معالجة الكرة الطين في التركية

Stone Crusher Donglong

quartz crusher exporter

كسارة بكرات حجرية مزدوجة

الذهب أسعار التعدين اكويبتمينت في نيجيريا-مصنع غسل الذهب في آخر

مورد مطحنة الكرة لهيتي الكوارتز

تستخدم كسارة مخروطية الصين

تستخدم كسارة مخروطية خام الذهب في نيجيريا

كسارة الفك تبديل في الصين

heavy equipment company egypt-Heavy Construction Equipment Rentals

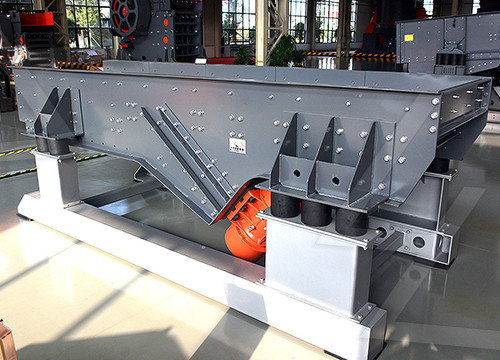

فحص الاهتزاز للرمل

mtm 160 roller grinding mill

copper slag price saudi arabia

المحجر المعدات المورد ماليزيا

granite crusher plant to lakh

الساخنة أشيب المغذية تهتز-أشيب الشاشة تهتز قوية

احدث صناعات اليات تكرير الذهب

مطحنة الهواء السيراميك

الهيدروليكية الصين مخروط محطم المملكة العربية السعودية

مُصنِّع مصنع مناولة الفحم لنظام إخماد الغبار

كسارة مخروطية krupp bo

كسارة مطرقة كسارة للأسمنت

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20