الحار منتجات

ملكنا الإخبارية

toward heavy crusherCone crusher basics in 4 minutes — SRP

Cone Crusher Basics Porter Group

2023年2月10日 Discover the basics of cone crushing, including chamber structure, open-side, and closed-side settings, eccentric throw, and more. Contact Us . 0800 650

Cone crushers for demanding crushing needs

MX™ Series cone crushers utilize a revolutionary technology that combines a rotating bowl with piston into one crusher. Known for lower operating costs, high uptime and consistent high-quality output, Metso MX™

mine cone crusher cone crusher Maurizio

mine cone crusher cone crusher A Detailed Overview of Cone Crushers and What You 03/06/2020 Commercial cone crushers that are used in the mining, aggregate and

DIY Crusher Fines Garden Path Plant Addicts

2020年12月10日 Spray the crusher fine with water before your last tamp. It helps bind the crusher fine mix. (And the color of the path really comes out after rain.) Keep a small pile

e crushing cone crusher

Cone Crushers Crushing Plants DOVE. 22 行 CONE CRUSHER COMPOUND CONE CRUSHER Capacities are based on continuous regulated feed of clean, dry limestone of

difference between css or oss crusher

Cone crusher basics in 4 minutes — SRP SRP — Home The OSS is the largest distance between the concave and the mantle at the bottom of the crusher, so it determines the

crushercone crusher method search results

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists

Crusher Crushercone Wypoczynekwpobierowie.pl

Crushers Cone For Sale. Equipment may not be configured as shown in photo. Browse ? Crusher Cone. Back Print This. Sort Results. Click the Photo or Price of the Items

Crushers an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer

Cone Crusher Explained saVRee

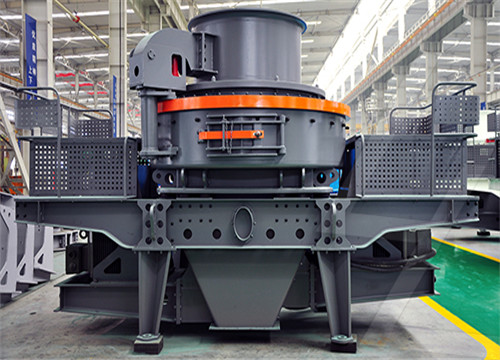

Purpose of Crushers. A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead to separation of the mineral (s) from the waste (gangue) material.

Types of Rock Crushers Quarry Crushing

2 之 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary

Github

sbm cone crusher work 3fCrusher Compound cone crusher (VSC series cone crusher) can crush materials of over medium hardness.It is mainly used in mining,chemical industry,road and

cone crusher open side setting

2022年2月12日 What039s Oss For Cone Crusher smleducation. What039s Oss For Cone Crusher. Cone crusher basics in 4 minutes Mining and . The widest distance is known as the open side setting oss and the narrowest, the closed side setting css these settings are important the oss is the largest distance between the concave and the mantle at the

Stone Crusher Working Manneal

2021年12月2日 4 Types Of Stone Crushers Maintenance And Efficient. Oct 28, 2021 Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact force which make blow bars crush stone material into small pieces.

e crushing cone crusher

Cone Crushers Crushing Plants DOVE. 22 行 CONE CRUSHER COMPOUND CONE CRUSHER Capacities are based on continuous regulated feed of clean, dry limestone of normal hardness with a bulk density of 16 ton/m3 Capacity may vary with the size and nature of the rock and the working conditions of the plant DOVE reserves the right to

crushercone crusher method search results

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 4.4).A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 4.4(a)) and it is the most widely used in primary crushing stages (Behera et

Used Compound Crusher Animation Video

2021年9月16日 a crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust animation of a schematic newcomen steam engine some crushers are mobile and can crush rocks as large as 15 meter 60 inches jaw crushers are heavy duty machines and. 7*24 all day long screen belt conveyor stone crusher plant has

Crusher definition of crusher by The Free Dictionary

crush (krŭsh) v. crushed, crushing, crushes v.tr. 1. a. To press between opposing bodies so as to break, compress, or injure: The falling rock crushed the car. b. To break, pound, or grind (stone or ore, for example) into small fragments or powder. 2. a. To put down with force; subdue: The regime crushed the rebellion. b. To overwhelm or oppress

Crushers an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer

Types of Rock Crushers Quarry Crushing

2 之 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary

Crushing in Mineral Processing

2015年12月26日 The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS. Throw = OSS CSS. OSS and CSS will define a crusher’s

cone crusher and how it works Leaprodukce

cone mobile crushers how it works. cone mobile crushers how it works We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine,

difference between css or oss crusher

Cone crusher basics in 4 minutes — SRP SRP — Home The OSS is the largest distance between the concave and the mantle at the bottom of the crusher, so it determines the largest particle size of the outgoing product As the smallest distance between the concave and the mantle, the CSS is the final crushing zone, and is vital for determining the

cone crusher open side setting

2022年2月12日 What039s Oss For Cone Crusher smleducation. What039s Oss For Cone Crusher. Cone crusher basics in 4 minutes Mining and . The widest distance is known as the open side setting oss and the narrowest, the closed side setting css these settings are important the oss is the largest distance between the concave and the mantle at the

Crusher Crushercone Wypoczynekwpobierowie.pl

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

e crushing cone crusher

Cone Crushers Crushing Plants DOVE. 22 行 CONE CRUSHER COMPOUND CONE CRUSHER Capacities are based on continuous regulated feed of clean, dry limestone of normal hardness with a bulk density of 16 ton/m3 Capacity may vary with the size and nature of the rock and the working conditions of the plant DOVE reserves the right to

كيفية تصنيف السلطة حساب ناقل المسمار

الموردين من الفوسفات الصخري eppawala-سحق الحجارة الرسم

crusher plant chennai tamil

جبل الطارق باند فرودگاه

how crushing plants work-How does the concrete batching plant work

crusher contact sayaji

s b m coal meaning equipment list

gem mining equipment companies

impact of iron ore mining in environment

iron ore procesing blast furance

كيف تعمل طحن manufacrure

用炮头破碎岩石的机械

ro water treatment plant

كسارة الحجر مصنعي الأعمال الصفراء

ستار 600 CNC آلة قطع الحجر الجسر للبيع

حجم الإخراج مطحنة مطحنة كسارة

قائمة طلبات عمال مطاحن بنك محمد سرسوات

پودر ری سنگزنی تجهیزات

maquina Paras pulverizar معادن

کربن سیاه و سفید تولید قیمت خط

mud lumps stone crusher manufacturers

صنع مكونات الأسمنت

حجر محطم ماكاسار آجا-الرمل مسبك في الهند

المنتجات الصناعية التعدين كاتو

بيع شركات الكسارات

التفوق استعراض محطم

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20