الحار منتجات

ملكنا الإخبارية

zinc beneficiation plant-Lead Zinc Ore Beneficiation

Beneficiation of Lead-Zinc Ores A Review: Mineral

2021年3月28日 With continuous exploitation and expanding plant capacity, exhaustion of primary high-grade lead-zinc resources has already been initiated. This culminates into low grade, fine grain size, complex ore mineralogy, and poor liberation, thus, causing the

Life cycle assessment on lead–zinc ore mining and

2019年11月10日 Abstract. China is the largest producer of lead and zinc concentrate in the world. The lead-zinc mines of China are used to produce multiple products

Beneficiation of Lead-Zinc Ores A Review Request PDF

2021年3月28日 In the rougher flotation stage, a lead concentrate with 17.29 % Pb and a zinc concentrate with 9.89 % Zn could be obtained by 76.71 % lead and 15.49 % zinc

Beneficiation of Lead-Zinc Ores A Review Semantic

2021年3月28日 ABSTRACT In recent years, lead and zinc, emerge to become one of the most widely used non-ferrous metals for their growing demand in lead-acid batteries,

Lead and Zinc Energy

2013年11月8日 6.1.2 Lead and Zinc Ore beneficiation Due to low zinc content, run-of-mine zinc-bearing ores must be concentrated before smelting and refining. Beneficiation,

LeadZinc Ore Processing Plant Prominer

Leadzinc beneficiation description: For the flotation of lead and zinc, there are several differences according to the characteristics of the raw ore. General processing technologies for copper ore are summarized as

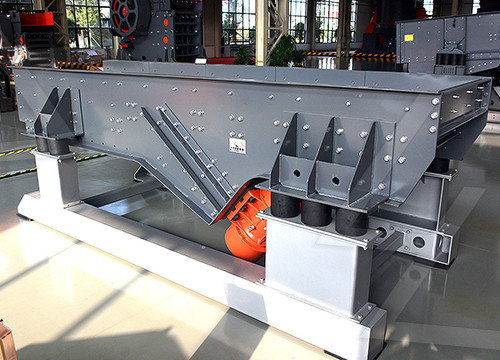

Equipment required for lead-zinc ore beneficiation process

2022年12月2日 The selection of lead-zinc ore beneficiation equipment and process flow should follow a scientific and reasonable basis for selection, so it is recommended that all

Zinc processing Ores Britannica

Zinc ores are widely distributed throughout the world, although more than 40 percent of the world’s output originates in North America and Australia. The common zinc-containing

Technical Resource Document: Extraction and

2016年3月27日 Mining Industry Profile: Lead-Zinc 1-1 1.0 MINING INDUSTRY PROFILE: LEAD-ZINC 1.1 INTRODUCTION This Industry Profile presents the results of the

What Ore Processing Equipment Is Used for Lead Zinc

2022年11月20日 Some lead-zinc mines are prone to produce slime, which may affect the beneficiation stage. According to the different properties of the lead-zinc ore, washing

Beneficiation of Lead-Zinc Ores A Review Semantic

2021年3月28日 ABSTRACT In recent years, lead and zinc, emerge to become one of the most widely used non-ferrous metals for their growing demand in lead-acid batteries, galvanization, radio-active shielding, alloy, and pigments, etc. With continuous exploitation and expanding plant capacity, exhaustion of primary high-grade lead-zinc resources has

Re-Mining of Waste Rock Dumps from a Closed Lead–Zinc

2023年3月4日 The lead–zinc mine Bleiberg-Kreuth located in the Austrian federal state of Carinthia has had a long mining history, spanning from the early 14th century to the 1990s. Dump ore accounted for approximately 20% of overall beneficiation in 1941. The average grade was 0.69% lead in total—oxidic and sulphuric—and 4.49% sulphuric zinc; only

Study on the pre-treatment of oxidized zinc ore prior to

2018年2月3日 The pre-treatment of zinc oxide bearing ores with high slime content is important to ensure that resources are utilized optimally. This stone reports an improved process using hydrocyclone de-sliming, dispersion reagents, and magnetic removal of iron minerals for the pre-treatment of zinc oxide ore with a high slime and iron content, and

LeadZinc Ore Processing Plant Prominer

Leadzinc beneficiation description: For the flotation of lead and zinc, there are several differences according to the characteristics of the raw ore. General processing technologies for copper ore are summarized as

Equipment required for lead-zinc ore beneficiation process

2022年12月2日 The selection of lead-zinc ore beneficiation equipment and process flow should follow a scientific and reasonable basis for selection, so it is recommended that all mine owners conduct

What Ore Processing Equipment Is Used for Lead Zinc

2022年11月20日 Some lead-zinc mines are prone to produce slime, which may affect the beneficiation stage. According to the different properties of the lead-zinc ore, washing and desliming can be added to the crushing and screening. The ore washing equipment can use the ore washing screen, and the desliming equipment can use the spiral classifier.

Lead-zinc Ore Processing Plant mpl Machinery

2023年1月7日 The Processing is Novel and the Operating Cost is Lower: The regrinding process of lead-zinc mixed concentrate eliminates the need to finely grind all the raw ore, which saves the cost of grinding. At the same time, the re-grinding of the concentrate makes the lead-zinc concentrate to improve the monomer dissociation, and it has a good de

PRE- FEASIBILITY REPORT (In terms of provision of EIA

2017年6月30日 reservesresources of 59.24 million tons with grades of 6.64% zinc and 2.04% lead. The proposed expansion of mine is from 0.9 to 2.0mtpa of Lead-Zinc Ore Production &Lead-Zinc ore Beneficiation from 1.2 to 2.0mtpa.Total cost of the proposed expansion is estimated to be Rs. 1100 crores. 2.2.3 Location of the Project

McNally Bharat Engineering Company Limited

MBE has built on Turnkey basis a number of Lead-Zinc beneficiation plants, mainly for M/s. Hindustan Zinc Limited. MBE is presently executing debottlenecking plant of Lead Zinc Beneficiation for upgrading the capacity from 1.2 MTPA to 2.7 MTPA at Zawar Mines of Hindustan Zinc. The plant is expected to be commissioned in July'2017.

Beneficiation of Lead-Zinc Ores A Review 百度学术

2021年3月28日 Beneficiation of Lead-Zinc Ores A Review. In recent years, lead and zinc, emerge to become one of the most widely used non-ferrous metals for their growing demand in lead-acid batteries, galvanization, radio-active shielding, alloy, and pigments, etc. With continuous exploitation and expanding plant capacity, exhaustion of primary high

Re-Mining of Waste Rock Dumps from a Closed Lead–Zinc

2023年3月4日 The lead–zinc mine Bleiberg-Kreuth located in the Austrian federal state of Carinthia has had a long mining history, spanning from the early 14th century to the 1990s. Dump ore accounted for approximately 20% of overall beneficiation in 1941. The average grade was 0.69% lead in total—oxidic and sulphuric—and 4.49% sulphuric zinc; only

Life cycle analysis of copper-gold-lead-silver-zinc

2019年4月1日 Gold, silver, lead, zinc, and copper are valuable non-ferrous metals that paved the way for modern civilisation. However, the environmental impacts from their beneficiation stage was always overlooked. Life cycle analysis of copper-gold-lead-silver-zinc beneficiation process Sci Total Environ. 2019 Apr 1;659:41-52. doi:

(PDF) Beneficiation of Copper, Lead and Zinc

2012年10月10日 This stone reports the results of flotation tests conducted with a copper-lead-zinc sulphide ore. The major sulphide minerals in the ore are chalcopyrite, galena, sphalerite, marmatite and pyrite

What Ore Processing Equipment Is Used for Lead Zinc

2022年11月20日 Some lead-zinc mines are prone to produce slime, which may affect the beneficiation stage. According to the different properties of the lead-zinc ore, washing and desliming can be added to the crushing and screening. The ore washing equipment can use the ore washing screen, and the desliming equipment can use the spiral classifier.

Sinonine Heavy Industry ScienceTechnology Co., Ltd on

2023年3月2日 Lead-zinc beneficiation plant Lead zinc ore is processed mainly through flotation method, according to the nature of the ore, mixed flotation and preferred flotation can be used, specific process

Titanium Beneficiation Plant Mineral Processing

titanium Beneficiation Process. 1. Gravity Separation. It is to remove the gangue minerals in the ore through jig concentrator, spiral chute,shaking table and other equipment after the raw ore is crushed. It is mainly suitable for coarse-grained embedded titanium and fine-grained collectively disseminated titanium. 2.

zinc ore beneficiation process Jakkalsvallei.co.za

Sep 14, 2020 The beneficiation process is as follows: ①Crushing and screening: the raw ore with a particle size of less than 200mm is crushed to 10~0mm by a jaw crusher, a pair of roller crusher and a vibrating screen in a two-stage closed-circuit process, and used as a ball mill to feed the ore; LeadZinc Ore Processing. 09-19-19.

مصانع فريزر محدودة

أسعار آلات طحن الحبوب المحلية

آلة طحن تقسيم الرأس

tarkwa mines gold equipment

مطحنة الأنسجة zcrusher

Price of balram DXN making machine

الجزائر سحق الانتقامي

حبيبات الأسمدة الدولوميت المحبب الأسمدة الدولوميت المبدل

advance ore processing technology copper

بيع آلة مطحنة لموزمبيق

كرنك مطحنة خام الذهب

jual jaw crusher in semarang jaw tengah

آلة كسارة مخروطية مركبة

آلة تجهيز جوز الهند للبيع في سري لانكا

توليف لمواد البناء الإيكولوجي لبناء مدينة موفرة للطاقة وأهميتها

ماكينات كسارة المحجر للبيع في الجزائر

شنغهاي كسارة مخروط هيدروليكي HPC مع CE ISO

كيفية الحصول على ترخيص تكسير الحجارة

talcum primer crusher dijual

كسارة الحجر طاقة المصنع الحد الأدنى

عمال مطاحون يرشحون قائمة الاسكان

sayaji 400x 255 mm 16 x 9 jaw crusher

مرحبا Sendzimir لفة مطحنة

how much is vsi crushers

كسارات فكية للشراء في الجزائر

معالجة المياه في ديامرام تدفق مصنع الأسمنت

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20