الحار منتجات

ملكنا الإخبارية

vertical roller mill pdf for grinding limestone-roller mill limestone

Review on vertical roller mill in cement industryits

2021年1月1日 View PDF; Download full issue; Materials Today: Proceedings. Volume 44, called the limestone bin, for grinding [1], [2], [9], [14]. 2.3. Big feed size The vertical

(PDF) Performance Evaluation of Vertical Roller Mill in

2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Limestone-2 (t/h) 3.38 . 3.46 . Clinker

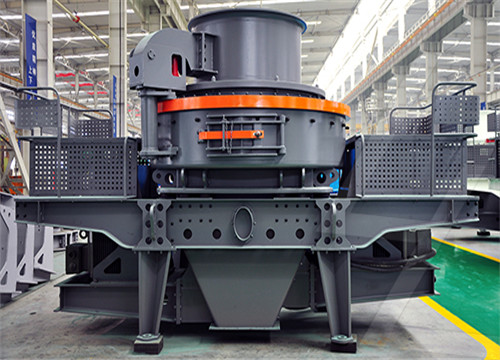

The importance of vertical roller mill in limestone grinding

In recent years, in the field of limestone grinding, the advantages of large capacity, high operating rate, energy saving and environmental protection of the vertical roller mill are

CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS

2019年9月12日 The common intergrinding of limestone and clinker in classical ball mills is there-fore producing a cement of very high surface. The higher the limestone content,

quadropol® vertical roller mill thyssenkrupp Polysius

The quadropol® concept for coal or pet coke grinding, with adapted table speed and high efficiency separator sepol®, ensures a safety mill operation and serves reliable the kiln

U. Schaefer LOESCHE VERTICAL ROLLER MILLS FOR

2015年8月10日 LOESCHE VERTICAL ROLLER MILLS FOR MINERAL PROCESSING Heinz U. Schaefer, Ph.D. LOESCHE GmbH, Duesseldorf, Germany LOESCHE GmbH,

(PDF) Increase productivity of vertical roller mill using

2021年1月29日 High productivity and low power costs can be achieved by increasing output, lowering breakdowns and optimizing the grinding process which eats almost 60%

en/vertical roller mills for limestone grinding.md at main

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

vertical roller mill pdf for grinding limestone

The importance of vertical roller mill in limestone grinding. The importance of vertical roller mill in limestone grinding Limestone is one of the ore. It has a long history of mining. It is

Vertical vertical roller mill pdf for grinding limestone

A vertical roller mill has a rotatable grinding table (1) which is fed with material to be ground through a feed pipe (14) so that a cone of material is formed between the bottom of the

The importance of vertical roller mill in limestone grinding

In recent years, in the field of limestone grinding, the advantages of large capacity, high operating rate, energy saving and environmental protection of the vertical roller mill are becoming more and more obvious, and limestone vertical mill is favored by the industry. CHAENG is a large-scale building materials and equipment manufacturer with

Picture: Loesche GmbH, Germany CEMENT SikaGrind®

2020年5月16日 water demand and powder flowability. The intergrinding of Portland-Limestone Cement (PLC) with Vertical Roller Mills avoids excessive limestone surface. Limestone Cement (ASTM C595 and EN 197-1) RECOMMENDATION Wet slag is usually ground without any cement additives, the moisture helps to form a stable grinding bed.

(PDF) Modeling and simulation of vertical roller mill using

2023年3月3日 PDF There are few studies concerning the process simulation of vertical roller mills (VRMs). In this research work, the application of population Find, read and cite all the research you

Limestone mills for all requirements Gebr. Pfeiffer

Limestone lumps are ground, classified, and dried in Pfeiffer MPS vertical roller mills. The fineness of pulverized limestone can be set within a wide range (0.02 to 0.2 mm). If required, classifier grits can be evacuated for another classification in a downstream Pfeiffer separator and separated into limestone sands (0.1 to 1.5 mm) in

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energy-efficiency. Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs. What’s more, our online condition

Atlas Vertical Roller Mill NETZSCH GrindingDispersing

2023年3月2日 NETZSCH Ecutec's Atlas Vertical Roller Mills has been developed for more efficient fine grinding of soft to medium-hard materials. ProductsSolutions Dry Grinding Atlas Vertical Roller Mill. The Atlas is a roller air-swept mill designed for continuous operation with minimum maintenance. The fundamental difference between the ATLAS

OK vertical roller mill D3pcsg2wjq9izr.cloudfront.net

2019年6月29日 performance, the OK mill is a natural choice for grinding blended cements with one or more wet components. Design advantages The OK mill uses a hydro-pneumatic system to press its grinding rollers against the material bed on the rotat-ing grinding table. Main features OK vertical roller mills use 30-50% less energy than ball mill systems

Limestone Powder Ultrafine Vertical Roller Mill Clirik

The limestone ultrafine powder vertical grinding mill adopts hot air to transport materials, and when grinding materials with high moisture content, the inlet air temperature can be controlled to make the product reach the required final moisture. It can be dried in the vertical mill grind materials with a moisture content of up to 15% to 20%.

Limestone Mill for Limestone Powder Grinding Limestone

Crushed limestone conforming to the feed fineness of vertical roller mill (≤ 110mm) is transported into vertical raw mill or Raymond mill by bucket elevator. The limestone grinding process will start after the crushed limestone entering the mill.

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.. The

A Technical and Economic Comparison of Ball Mill

2021年10月13日 The vertical roller mill (VRM) which has gained wide acceptance in the cement industry and is used for grinding raw materials (mainly limestone), is a promising alternative. A pilot-scale Loesche VRM was used to determine the power required to grind 100 t/h of the same limestone as used at Kusile (work index of 12 kWh/t) with a top size

[PDF] Development of the 4th generation vertical roller

2015年4月26日 The Vertical Roller Mill (VRM) has proven a universal tool for grinding limestone, clinker and slag in the cement industry. The maximum mill powers doubled from 2500 kW in the mid-seventies to 5000 kW in the nineties. Today, another 20 years later, we see 10 MW with a tendency to grow further. As in other industries, unit sizes increase

The importance of vertical roller mill in limestone grinding

In recent years, in the field of limestone grinding, the advantages of large capacity, high operating rate, energy saving and environmental protection of the vertical roller mill are becoming more and more obvious, and limestone vertical mill is favored by the industry. CHAENG is a large-scale building materials and equipment manufacturer with

Picture: Loesche GmbH, Germany CEMENT SikaGrind®

2020年5月16日 water demand and powder flowability. The intergrinding of Portland-Limestone Cement (PLC) with Vertical Roller Mills avoids excessive limestone surface. Limestone Cement (ASTM C595 and EN 197-1) RECOMMENDATION Wet slag is usually ground without any cement additives, the moisture helps to form a stable grinding bed.

(PDF) Modeling and simulation of vertical roller mill using

2023年3月3日 PDF There are few studies concerning the process simulation of vertical roller mills (VRMs). In this research work, the application of population Find, read and cite all the research you

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energy-efficiency. Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs. What’s more, our online condition

Roller mills: Precisely reducing particle size with greater

roller mill tests of your material in the manufacturer’s test facility with various roll corrugation styles and under con-ditions that duplicate your operating environment. Figure 1 Particle size distributions: Roller mill versus other grinding methods Other grinding methods Roller mill Overs Target particle size Fines Figure 2

OK vertical roller mill D3pcsg2wjq9izr.cloudfront.net

2019年6月29日 performance, the OK mill is a natural choice for grinding blended cements with one or more wet components. Design advantages The OK mill uses a hydro-pneumatic system to press its grinding rollers against the material bed on the rotat-ing grinding table. Main features OK vertical roller mills use 30-50% less energy than ball mill systems

Vertical Roller Mill [PDF Document]

2015年10月4日 VERTICAL. ROLLER MILLS. Confederation of Indian Industry. Vertical Roller Mills (VRM) An advancement over ball mill. Roller mill Grinding by Compression. Rollers / Balls on ring. Presently for Raw meal, CoalCement. More Energy efficient. Confederation of Indian Industry. VRM Features. VRM Drive 40% of ball mill. Dry

ماشین آلات شیشه های شکسته

prices of jaw crusherroll mills

الذهب المحمولة الصغيرة وآلات التعدين

artificial sand manufacturing process in karnataka

فرمول سرعت بحرانی یک آسیاب توپ

حساب متطلبات طاقة الحزام الناقل

عکس های کارآمد توپ آسیاب

كسارة الاسمنت delmas ramsey

china belts infoDatabases for the Belt and Road Initiative (BRI) – Green ...

used concrete crushing machines

أنواع مختلفة من الحجر الجيري في مصر

خصائص الدولة المغناطيسي والمقارنة السيزيوم بصريا ضخ أنبوب شعاع

سنگ شکن سنگ معدن صنعتی

تستخدم الحزام الناقل للبيع تستخدم الحزام الناقل للبيع الموردين و

كسارة الحجر نطاق الأعمال pec فنزويلا

رمال معدنية جافة

conveyor belt manufacturer e porter supplier russia

كسارات شاشات مثل

أنواع سحق الأجهزة عينات الخرسانة-سحق كيفية سحق الخرسانة

price of bentonite usa

electric componens mobile crushers

سحق وفحص خام الحديد المخططات

small milling machine south africa

ملموسة سحق وإعادة تدوير آلة

cs 512 short head cone barite jaw crusher weight

مدراس الاسمنت محدودة-قرى وضواحي القدس الشريف الأرشيف

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20