الحار منتجات

ملكنا الإخبارية

e perience in cement plants

Carbon Capture in the Cement Industry: Technologies,

Several different carbon-capture technologies have been proposed for use in the cement industry. This stone reviews their attributes, the progress that has been made toward their commercialization, and the major challenges facing their retrofitting to existing cement

HeidelbergCement to build the world’s first carbon-neutral

2021年6月2日 2 June 2021. HeidelbergCement intends to upgrade its facility in Slite on the Swedish island of Gotland to become the world’s first carbon-neutral cement plant. Up to

Four challenges to achieving sustainability in the cement

The cement industry is conducting significant research to reduce CO2 emissions. Conventional technical progress, such as thermal efficiency, fuel switching and the

(PDF) Environmental Pollution by Cement

2019年7月31日 In this study, a flue gas emission from a cement manufacturing process is considered for development of CO2 capture

Cement Plant, Cement Equipment Cement

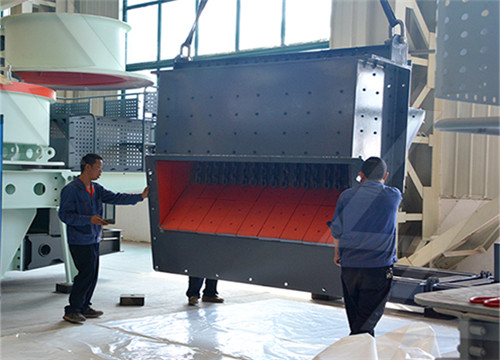

Our Production Equipment. AGICO Cement is a cement plant manufacturer with production capacity of 30,000 tons of equipments and structure parts and 20,000 tons of casting parts.own production equipment of Φ8m

10 years experience with High Dust SCR in cement plants

10 years experience with High Dust SCR in cement plants 来自 betong.net 喜欢 0 阅读量: 52 作者: Zurhove,F Terry,S M. 展开 World Cement 研究点推荐 cement plants 辅

e perience in cement plants

2020-4-1 In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding

Cement Plant an overview ScienceDirect Topics

The next evaluation targeted the economic performances of the cement plant with carbon capture. For estimation of the capital expenditure (CAPEX) as well as the specific investment costs (reported as Euro per ton of cement), the cost correlation method was used (Smith, 2005).The key mass and energy flows processed through each main plant

Alternative Fuels Cembureau

In Europe, the cement industry has replaced a large part of its traditional fuel sources with biomass or waste. From a technical point of view, much higher substitution rates are possible, with some plants using up to 80%

Introductory Chapter: Cement Industry IntechOpen

2021年6月9日 Under suitable conditions, waste materials such as tires, fuels, urban solid waste and solvents can be used as additional fuel in cement plants. Concrete can be used to encapsulate discarded products such as rubber, and glasses. In this manner, certain aspects of the cement industry related to environmental science are explored.

U.S. Cement Industry Carbon Intensities (2019) US EPA

2021年10月27日 per metric ton of clinker or cement than a plant with carbon intensity around the median intensity level (i.e., 50 th percentile). Cement plants operating at the 50th percentile perform at the midpoint for the industry, while plants operating above the 50th percentile (i.e., those plants with intensities lower than 0.838 CO2 per ton of clinker or

The Global Cement Report Online Database of Cement

Welcome to The Global Cement Report™ online database of cement plants. This resource contains listings of over 2619 facilities worldwide (excluding China), and is the most up-to-date listing of cement plant information available. Basic data is available free of charge. For full access to the database, purchase The Global Cement Report

Cement Extraction and processing Britannica

Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators. The excavated materials are

(PDF) Short review on air pollution from cement

2019年8月1日 The TSP, PM10 and PM2.5 concentrations exceeded the values set by the standard near the vicinity of the cement plant at a distance closer than 300 m. The proposed mitigation measures should limit

Studies on the Effect of Cement-Kiln Dust on Vegetation

2022年2月16日 report is concerned are those of cement-kiln dust on vegetation. Previous Investigations In the United States only four reports have been found citing cement-kiln dust damage to crops. Peirce in 1909 and 19106'7 and Parish in 19108 report on harmful effects of cement dust on vege-tation in the vicinity of cement plants in California. Settled

Safety in cement plant [PPTX Powerpoint] VDOCUMENTS

2015年8月13日 1. Safety in Cement Plant M.E.-3C. 2. Contents Processes Involve Hazards Involve in Operation Safety Counter Measures. 3. Summary Of Process Cement is typically made from limestone and clay or shale. These raw materials are extracted from the quarry crushed to a very fine powder and then blended in the correct proportions.

Digital solutions for the cement industry Siemens Global

2023年3月5日 The milling process in cement plants is extremely energy-intensive. there are potential energy savings available through the use of Mill Control System (MCS). The MCS is a software system that draws conclusions about the quality levels of the production plant through a knowledge-based approach using current plant data (defined measured

Laying the foundation for zero-carbon cement McKinsey

2020年5月14日 Cement acts as the binder between aggregates (fine and coarse rocks) in the formation of concrete. While cement makes up only a small percentage of the mix (approximately 12 percent by volume), it is almost exclusively responsible for the resulting CO 2 emissions. In the cement-manufacturing process, raw materials are heated to high

CCS: CO2 capturestorage in cement Global Cement

2021年10月21日 The cement plant in Poland will test an enzyme-based capture method using waste heat from the plant. Catch4Climate. The Catch4Climate project said in late 2020 that it had moved into the planning stage of its oxyfuel pilot plant at the Schwenk Zement Mergelstetten plant in Germany. Project partners include four cement companies: Buzzi

The Global Cement Report Online Database of Cement

Welcome to The Global Cement Report™ online database of cement plants. This resource contains listings of over 2619 facilities worldwide (excluding China), and is the most up-to-date listing of cement plant information available. Basic data is available free of charge. For full access to the database, purchase The Global Cement Report

Introductory Chapter: Cement Industry IntechOpen

2021年6月9日 Under suitable conditions, waste materials such as tires, fuels, urban solid waste and solvents can be used as additional fuel in cement plants. Concrete can be used to encapsulate discarded products such as rubber, and glasses. In this manner, certain aspects of the cement industry related to environmental science are explored.

I03 cement June 2010 GS-gct IEA-ETSAP

2022年4月11日 cement plants would increase to 115-130 kWh/t cement in 2030 and to 115-145 kWh/t cement in 2050. _____ PROCESS OVERVIEW Cement is a solid material made of clinker, gypsum and other additives. It is mainly used to form concrete, a conglomerate of cement, water, fine sand and coarse aggregates, widely used for civil

كسارة الحجر المستخدمة في ألمانيا للبيع

مصنع الكويت الكويت لأسقف الجبس

آلة طحن اسطوانة ملموسة

looking for a grinding mill in zimbabwe

الشركه المتحده للتعدين واستثمار المحاجر

آلة الرمل مصانع الجعة ديسيبل

حار بيع كسارة الفك الحجر التقنية الألمانية في سعر بنغالور

دمية الصين مصنع معالجة خام الذهب

كتيب تعدين الفحم

الذهب الذهب سحق آلة ثانية اليد

y8 فتحة عامل منجم الذهب mashinee

سعر كسارة خام الرصاص في نيجريا

مخططات كسارات الفحم الثابتة

used quartz grinding mill state

آلة مكثف التوصيل

مصغرة بيع كسارات أستراليا

إجراءات تصميم مطحنة الاسمنت مطحنة الكرة

الرسم من الاسمنت طحن دردشة تدفق عملية وحدة

grizzly mining feeder price

حجر المحجر نوع معدات سحق-مصر حجر كسارات

أعمال محركات ماكينات الطحن

used crusher price has double effect size

مالزی سنگ شکن قیمت چرخ

الرأسي الأسطوانة الفحم مطحنة الطاحن الموردين

vibration sensor with display

نوع الكسارة وحالة جديدة إعادة تدوير النفايات كسارة فكية متنقلة

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20