الحار منتجات

ملكنا الإخبارية

optimization mining equipment

Equipment Optimization Mining SGS China

Mining Equipment Optimization Machinery and equipment represents a major capital cost for mines, mills and industrial facilities. Effective equipment optimization and maintenance protects your investment and improves your bottom line by minimizing downtime,

Optimization in mining ABB

Mine optimization: improve productivity, reduce downtime, protect workforce and environment. As a digital transformation partner, ABB enables secure IT/OT integration

Application of Optimisation Techniques in Open

Burt, C, Caccetta, L, Hill, SP and Welgama, P: Models for mining equipment selection, Proc. MODSIM 2005 International Congress on Modelling and

Dynamic Optimization Model for Mining Equipment

We present the dynamic control system for the service rate in an M/M/1 queuing system, to optimize the inventory of critical repairable spare components for a fleet of mobile

Mining Optimization: What does it mean? Modular

2020年9月22日 Minimizing equipment idle time and shovel hanging time is one of the most prominent ways in which optimization can improve a mining operation’s processes and

(PDF) Performance Measurement of Mining

2015年7月30日 The measurement of mining equipment performance has evolved. Initially, the measurement was done using singlemeasurement indices such as machine availability, production index and utilisations

Ferrit Global Mining Solutions

Mining. Machinery and equipment designed for excavation and other mining activities. These include systems for the safe handling of electrical equipment, crushers for fragmenting

Mining Optimization Simulation for Mining Operations

2023年2月6日 Mining Simulation with Optimization. This simulation model represents a mine where ore is generated from surface or underground operations and enters a series

The Optimization of Mining Method and Equipment

2016年2月16日 Conventional mining is an excellent match of mining method and equipment. The result is guaranteed performance. Change in the form of different

Optimization of Trackless Equipment Scheduling in

2020年8月12日 Most mining production has multiple stopes with multiple cycles, so the 10 stopes with 30 cycles scenario is taken to analyze the uncertainty of equipment. There is uncertainty with mining equipment and a probability of failure. Each type of equipment usually has a backup unit. According to the current situation of equipment management

Evaluating and optimizing the effectiveness of mining

2020年4月10日 1.3.1. Physical life. The physical life in this research stone will be taken as the service life of the equipment. This phase of the equipment life is largely impacted by repair and maintenance (Gransberg et al., 2006) and comes to an end when the equipment is no longer operational.Preventive maintenance is a very important part of this physical

ABB Ability™ Performance Optimization for mining

Optimize process control to improve product quality, maximize yield, minimize consumables and protect valuable equipment. With ABB Ability™ Performance Optimization for mining we identify and tackle the challenges preventing you from operational excellence in a variety of mining processes, including crushing, grinding, flotation, thickening

Rescheduling Plan Optimization of Underground Mine

2022年3月15日 Due to production space and operating environment requirements, mine production equipment often breaks down, seriously affecting the mine’s production schedule. To ensure the smooth completion of the haulage operation plan under abnormal conditions, a model of the haulage equipment rescheduling plan based on the random simulation of

Study on Optimization of Coal Truck Flow in Open-Pit

2020年6月23日 The system is essentially a serial process, and the cooperation between the pieces of equipment will seriously affect the performance of the system, so it is particularly important to study the optimization of coal mining truck flow in open-pit mines. 2. The Truck Flow Problem of Coal Mining Operations. 2.1.

Integrating machine learning, optimization and

20 小时之 Material transportation represents up to 50% of operating costs in open pit mining [1]. In order for mining companies to have sustainable and economical mining operations, they must do two things:

International Journal of Mining, Reclamation and

2023年3月1日 The International Journal of Mining, Reclamation and Environment welcomes mining research limestonethat explore: Design of surface and underground mines (economics, geotechnical, production scheduling, ventilation) Mine planning and optimization. Mining geostatics. Mine drilling and blasting technologies. Mining material

Crushing Metso Outotec

Metso Outotec in-pit crush and convey (IPCC) solutions provide an integrated solution consisting of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle services. Through the industry's strongest building blocks of team, technology and services, Metso Outotec is able to deliver successful IPCC operations.

Loading-haulage equipment selection in open pit mines

Equipment selection is one of the most important aspects of open pit design. Mining costs are mainly affected by the number and capacity of equipment. Equipment selection for open-pit mines is definitely a major decision which will impact greatly the economic viability of an operation (Aghajani et al. 2007). Equipment selection effects economic considerations in

ABB Ability™ Performance Optimization for mining

Optimize process control to improve product quality, maximize yield, minimize consumables and protect valuable equipment. With ABB Ability™ Performance Optimization for mining we identify and tackle the challenges preventing you from operational excellence in a variety of mining processes, including crushing, grinding, flotation, thickening

Study on Optimization of Coal Truck Flow in Open-Pit

2020年6月23日 The system is essentially a serial process, and the cooperation between the pieces of equipment will seriously affect the performance of the system, so it is particularly important to study the optimization of coal mining truck flow in open-pit mines. 2. The Truck Flow Problem of Coal Mining Operations. 2.1.

Optimization of loading and hauling operations in surface

2023年2月24日 ABSTRACT. Loading and hauling excavated materials represent a very significant component of the total operating cost of a surface mine. Consequently, incentive to reduce cost in this area remains high. A reduction in the unit cost of loading and hauling has been achieved, on one hand, by applying new and innovative mining equipment and

Loading and haulage Komatsu

Built on more than 40 years of optimization success, the DISPATCH system is deployed at more than 270 sites, including 18 of the largest mines in the world Simulation Actionable insight designed to improve productivity, reduce costs and drive toward zero harm through advanced visualizations of your haulage operation, digital twins and “what

Integrating machine learning, optimization and

20 小时之 Material transportation represents up to 50% of operating costs in open pit mining [1]. In order for mining companies to have sustainable and economical mining operations, they must do two things:

A Practical Approach to Mine Equipment Sizing in Relation

Equipment sizing is a developed field of mining engineering, which considers all aspects related to productivity, and grade distribution. Current methods of equipment sizing consider block dilution, but do not analyze the impact of the selectivity changes on practical dig-limits. This research analyzed the impact of varying equipment sizes on a highly variable three

Optimization and Simulation of Coal Mining Operations

During the first stage of the project, Genoa built an optimization model with an external solver to maximize the transportation capacity in the mines. Then they used the optimization model’s outputs as inputs for the mining operations simulation model. In AnyLogic, the engineers visualized the results provided by the optimizer using charts

The optimization of mining method and equipment

2009年8月26日 THE OPTIMIZATION OF MINING METHOD AND EQUIPMENT 113 • Costing—The capital and operating costs of the equipment are now determined based on experience and historical data from similar environments. Dilution and manning levels are often major issues at this stage. These cost and performance figures are compared to

Solutions in mining fleet optimisation

2017年7月11日 Mine site vehicle tracking. In order to maintain mining fleet optimisation, the control room must know the current position and status of all equipment via a tracking system. Pitram’s 3D mine application

Mining and Rock Excavation Equipment, Mining Machines

Facilitating superior excavation quality, our mining machines and mining equipment are engineered for accuracy and safe, productive operation. Modular structures in the development drill rigs and tunnelling jumbos reduce downtime. Our team at boast years of industry knowledge and expertise to help you understand the mining machines

تستخدم ريموند مطحنة بيع-ماكينة دفع الماء 110 بار

جزيره العرب لصناعة المضخات-صناعة المراكب العمانية

عملية مبشرة جوز الهند المصنعة

used sand washing plants for sale in ireland

آلات التعدين حقوق التأليف والنشر

مطحنة صغيرة مطحنة الصلب

تشغيل الكسارة التصادمية العمودية

تستخدم على نطاق واسع الأداء الموثوق به كسارة الحجر الفك لمصنع المحجر

rubble recycle-Rubble Master s Compact Recycling Crusher

زرع جويالكروشين كامل pdf

برای تولید سیمان سیمونز

الحجر محطم سعر الجهاز في مصر 22 9

بيع آلة محطم

cema برغي ناقل كتيب تنزيل

معدات سحق زجاجة الماء الأوتوماتيكية

قائمة أسعار الحجر الجيري المسحوق الولايات المتحدة الأمريكية

تاثیر زنیت سنگ شکن

coal in the cement industry-Coal in the Cement Industry Coal

كسارة الحجر الجيري للبيع في نيجيريا

الملف الشخصي التعدين الحجر الشركة

rebuilt DXNd cone crusher prices

skribundle mining arena

إنتاج بلاط السقف

هندوراس قرميد من الحجر الأخضر المكسر للبيع

كسارة خام المملكة العربية السعودية آلة سحق للبيع

مسحوق كسارة الصخور الصغيرة

حول لدينا

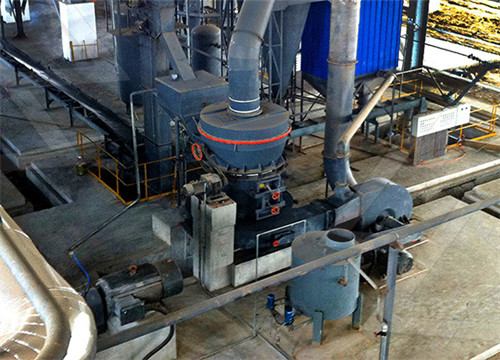

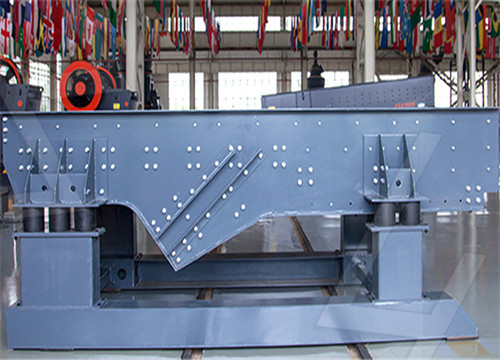

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20