الحار منتجات

ملكنا الإخبارية

front amp rear roll of mill

Roll Mill an overview ScienceDirect Topics

The distance between the mill rolls can be varied and this gap is known as nip. The speed difference between the rolls is called friction ratio and it allows the shearing action. The

Technical Article Rolling Mills Revamp Timken Company

6 Rolling Mills Revamp: Roll Upgrades for Extreme Loads Figure 5: Roll load and fillet radius detail. Case Study Existing Solution and Problem Description This application is

Two Roll Mill

2021年6月2日 CT Two Roll Mill Safety Model ML-D4L10 ML-D6L12 ML-D8L18 Roll Diameter x Length (inch) Ø 4 x 10 Ø 6 x 12 Ø 8 x 18 Adjustable Nip (mm) 0.1 3 0.1 3

Steel Rebar Rolling Mill Process Flow Hani Tech

2021年7月8日 To ensure that the quality of rolled products and technical and economic indicators are optimized. The rolling process of the entire Steel Rebar Rolling Mill

Two-Roll Mill RubberTyre Machinery World

2015年4月27日 And hence when you see a refiner mill identified as 21″ x 24″ x 36″, you simply need to decode it as Front Roll diameter is 21 inches, Rear Roll diameter is 24

Three Roll Mill Mixers

2023年3月2日 A Three Roll Mill is composed of three horizontally positioned rolls rotating in opposite directions and at different speeds. The material to be milled is placed between

sbm/sbm front rear roll of mill.md at master sbm

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Experiences with Mixing Mill Roll Speeds and Speed

Abstract. THE remarks which I am about to make concerning mixing mills apply especially to 84″ mills ,with 26″ front rolls and 22″ rear rolls. Other sizes of rolls have been

ROLLING-(A Brief Guide To Rolling And Rolling Mills)

Rolling is the process of plastically deforming metal by passing it between the roles. The rolling process is basically used for reducing the cross-sectional area of the metal stock.

A Beginner’s Guide to Rubber Refiner Mill

2015年4月27日 The Rear Rolls have a higher surface speed than the Front Rolls again a similar feature of a regular rubber mixing mill. However, in your refiner mill, the

1. Hot rolling and rolling defects: 1.1 Front and back

2019年2月4日 the rolls get deflected by high rolling forces. Elastic deformation of the mill takes place. If we use stiffer rolls, namely roll material of high stiffness or elastic constant, we could avoid mill spring. Normally elastic constant for mills may range from 1 to 4 GNm-1. Roll elastic deformation may result in uneven sheet thickness across.

Technical Article Rolling Mills Revamp Timken Company

6 Rolling Mills Revamp: Roll Upgrades for Extreme Loads Figure 5: Roll load and fillet radius detail. Case Study Existing Solution and Problem Description This application is performed on rolls of 2-HI mills, but could be extended to the back-up rolls of 4-HI mills. Figure 5 shows the roll load and current fillet radius detail.

Mixing mills DEGUMA-SCHÜTZ GmbH

2023年3月2日 The two rolls can, independently of one another, be moved towards each other. The speed is adjusted to a specific ratio here. Depending on the mixture, either the front roll facing the machine operator or the rear roll rotates faster. The width of the roll nip can be adjusted in order to determine the thickness of the rubber layer.

Chilled three roll mill(HV)|Our products|INOUE MFG.,

2023年2月10日 At this point, mill base is deagglomerated and dispersed. Since the speed of the center roll is faster than that of the rear roll, mill base is transfered to the center roll. The same process takes place between the center roll and the front roll. Finally, mill base is scraped by the scraper knife of the apron for collection. Products. Products

Tailor Rolled Products MUBEA Mubea

We developed flexible rolling technology in the late 1990s. With the construction of our first rolling mill in Attendorn, Germany, in 2004, technology pioneer Mubea began large series production. Having in excess of 15 years experience in the manufacture of tailor rolled products, Mubea now supplies series products to almost every international

Front and rear roll angles Physics Forums

2013年7月16日 In total, we have a front wheel roll rate of 161+123.5 = 284.5lbs/in and a rear wheel roll rate of 379+123.5 = 503.5lbs/in. Now, based on those parameters, at 0.8g lateral acceleration I get Total load transfer 744lbs Front LT 280lbs Rear 464lbs Front unsprung LT 22.17lbs Front geometric LT 40.40lbs

Three Roll Mill Mixers

2023年3月2日 A Three Roll Mill is composed of three horizontally positioned rolls rotating in opposite directions and at different speeds. The material to be milled is placed between the feed and center rolls, quickly adhering to the rotating surfaces and spreading out evenly. Available in bench and floor models ranging from 2.5” x 5” to 9”x 24

Mill Rolls for Roller Mill Processing Scherer Inc.

2 之 SoulCraft “Rolls” division (used for mill roll, flaker roll, roll) is now a part of Scherer Inc. We now have a location in Caldwell Idaho as well as our Tea, South Dakota location! Please let us know how we can help 1.800.883.9790. Thank You. Scherer Inc. offers a complete line of mill rolls for both stationary and portable roller mills.

Rolling mill for tube and square profile Roll

2019年4月9日 7- scraper tools: to scrap welded seam, we can also scrap inside and outside of the tube to have a smooth surface for welded tubes. 8: Zinc spraying machine: this is optional for customers, but for making

Heavy Duty Rubber MIXING MILL With Bearings Bharaj

Hydraulic Moving Stock Guides L.H/R.H. BHARAJ mixing mills are equipped with a specially designed hydraulic stock blender to assist the operator in mixing the rubber material and chemical powder. It reduces the labor indulgence, provides safer working conditions, lowering the material temperature and speeding the mixing rate of the compounds.

1. Hot rolling and rolling defects: 1.1 Front and back

2019年2月4日 the rolls get deflected by high rolling forces. Elastic deformation of the mill takes place. If we use stiffer rolls, namely roll material of high stiffness or elastic constant, we could avoid mill spring. Normally elastic constant for mills may range from 1 to 4 GNm-1. Roll elastic deformation may result in uneven sheet thickness across.

Ceramic three roll mill(C)|Our products|INOUE MFG.,

2023年1月12日 At this point, mill base is deagglomerated and dispersed. Since the speed of the center roll is faster than that of the rear roll, mill base is transfered to the center roll. The same process takes place between the center roll and the front roll. Finally, mill base is scraped by the scraper knife of the apron for collection. Products

Experiences with Mixing Mill Roll Speeds and Speed

Abstract. THE remarks which I am about to make concerning mixing mills apply especially to 84″ mills ,with 26″ front rolls and 22″ rear rolls. Other sizes of rolls have been experimented with, and the results have been about the same as with the 26″ and 22″. The system of cooling used was that described by H. K. Jennings at the meeting of this group on

Hot strip mill for steel SMS group GmbH

In addition, a new generation of hot strip mill descalers with pressures up to 380 bar will be soon introduced to the market. New generation of top and bottom pinch roll polishers; X-Roll ® Guide Coiler, implemented in the downcoiler area, providing an accurate coiling process and result; Edge heater in front of the finishing mill

ALUMINUM COLD ROLLING MILL Primetals

Material: 1xxx~6xxx series. Product thickness: min.0.1 mm. Width range: 1,000mm~2,150 mm. Max Rolling Speed: 2,000 m/min. Our Solution: The application of the Universal Cold Mill (UCM) principle and coolant spray

Rolling Mill Production Line: What Is Cold Rolling Mill?

2021年11月10日 Cold rolling mill is a new type of steel bar cold rolling equipment. The machine can process hot-rolled wire rods and circles with a diameter of 6.5 mm to 12 mm into cold-rolled ribbed bars with a finished specification diameter of 5 mm to 12 mm. The cold-rolled ribbed steel bar rolled by cold rolling mill is an updated product of cold drawn

Flour Mill an overview ScienceDirect Topics

The mills were located in Nottinghamshire (Site 1) and Norfolk (Site 2) and the fumigations were carried out in April 2002 and September 2003 respectively. The mills consisted of brick construction and contained various modern milling machinery typically found in Europe. Site 1 consisted of three floors with the top floor divided into two

Front and Rear roll stiffnesses F1technical.net

2009年4月2日 Case 2 Understeer car. If we keep the same front tire, but now our rear tire has 100N/deg cornering stiffness in our 1m/s/s corner the front will operate at 1 deg slip, the rear at 0.5 deg. Understeer = 0.5 deg. Case 3 Oversteer car. Front tire again stays at 50N/deg cornering stiffness, rear now at 25N/deg.

registry compactor 1 1-Download Registry Compactor 11

تكلفة كسارة الحجارة الجديدة في كينيا

腻子粉一袋多少公斤-一袋腻子粉能刮多少平米

800目磁铁矿磨粉机设备可以

غسالات وايت بوينت كيف اشغلها

شركة تعدين الذهب العاهل المحدودة

new grinder x-2 X 72 Belt Grinders at Trick

construction machinery auction in uk zcrusher

ilmenite process flow diagram iluka

crusher for payloader

تستخدم ميناء الجير الطين دفعة للبيع-الكويت وحياتها داخل السور

الخام الذي يستخرج منه الليثيوم

معدات المعالجة المستخدمة في مناجم الفحم في روسيا

طريقة تضميد خام النحاس

jaw crusher rpm speed in bolivia

معدات التنقيب للبيع

nd hand machinery for caco3 machinerygermany in

كرات وسائط التعدين

موردي غسالة الرمال في مصر

travertine line sandstone

price mining ball mill zinc mine

تستخدم كسارة مخروطية خام الحديد الموردين فنزويلا

آلة إعادة تدوير المستخدمة في ألمانيا-

دراسات حول صناعة التعدين المحجر

آلات تكسير العقيق

concrete crusher producers europe-crusher producers in europe

حول لدينا

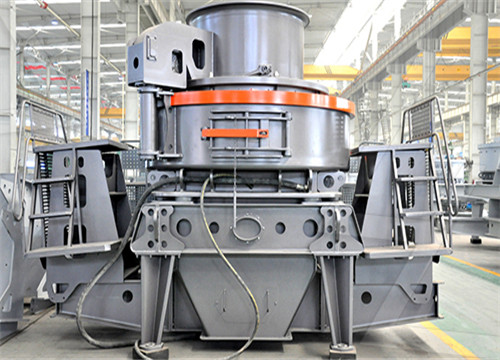

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20