الحار منتجات

ملكنا الإخبارية

effect of pulp density in froth flotation-Effect of Oxygen and Micro

Considering the effect of pulp chemistry during flotation

2018年1月15日 Within the flotation process the pulp phase chemistry has a strong effect on the froth phase and therefore the manipulation of pulp chemistry factors such as the pulp potential (Eh), pH, dissolved oxygen (DO) and ionic strength (IS) can improve flotation

Considering the effect of pulp chemistry during flotation

2018年1月15日 Through all four figures (Fig. 3, Fig. 4, Fig. 5, Fig. 6) three distinct regions were observed, namely, a high Eh region (1IS, pH 9, 700–730 mV), a pH 11 region (1 IS,

Considering the effect of pulp chemistry during flotation

2017年11月1日 Abstract. Within the flotation process the pulp phase chemistry has a strong effect on the froth phase and therefore the manipulation of pulp chemistry factors

Effect of operating parameters on desulphurization of

2012年4月30日 The effects of operating conditions such as the froth depth, air flow rate, impeller speed, and pulp density on desulphurization of MT have been investigated. This

The Effects of Frothers and Particles on the

2016年1月1日 The pulp and froth zones are the main components of froth flotation as it defines both quality of the end product and overall

Effect of solids on pulp and froth properties in flotation

2014年4月1日 The results show that in the pulp zone there is no effect of solids on bubble size and gas holdup; in the froth zone, although hydrophilic particles solely do not effect

(PDF) The Critical Role of Pulp Density on Flotation

2018年7月26日 The effect of pulp density was à0,09 for a variation of 5%; This observation (also shown in Fig. 2a) indicates that reducing the pulp density lead to an increase in the

The effect of pulp bubble size on the dynamic froth

2019年1月15日 This study focussed on the effect of pulp bubble size on froth stability. Different pulp bubble sizes were generated in a non-overflowing column and time

Design and construction of a continuous pilot flotation

2022年11月7日 1.Introduction. Flotation is largely dependent on differences in surface wettability of valuable species and gangue in an aqueous slurry or pulp (Hanumanth and

Study on surface physical and chemical mechanism of

2023年3月3日 The particle size distribution of UFG and FFG samples were analyzed using a laser particle size analyzer BT-9300S (Bettersize Instrument Ltd., Dandong, China) and

Beneficiation of oil shale by froth flotation SpringerLink

2018年7月21日 In the future, oil shale will be an important energy resource. Froth flotation is a new method increasing the usability of oil shale. In this , oil shale samples were characterized based on their mineral composition, proximate analysis, ultimate analysis, size distribution, and density analysis. In addition, the flotation performance of oil shale was

FKDUDFWHULVDWLRQLQ

2019年5月21日 froth rheology change was not yet clear [27]. A more viscous pulp may result in a more stable froth [28]. Li et al. has exclusively investigated the froth rheology and its effect on flotation performance in recent years [21, 29-31].They have observed correlation between froth viscosity and mineral recovery in froth flotation process. Figure 5.

A Brief Review of Pulp and Froth Rheology in Mineral

2020年2月8日 In mineral flotation, rheological problems have limited the efficient upgrading of low-grade and complex ores. Since pulp and froth rheology are deemed to play different roles in influencing the separation performance, in this , a brief review on pulp and froth rheology in flotation is provided, with an objective of developing a basic

Effects of Operating Parameters on the Froth and

2021年5月7日 The effects of flotation operation parameters, including froth depth, air flowrate, and frother dosage, on the froth and collection zone recovery and the flowrate of particles into the froth phase were investigated in a 10 m3 industrial cell. The results showed that froth recovery increases upon increasing air flowrate and frother dosage, as well as

Study on surface physical and chemical mechanism of

2023年3月3日 The particle size distribution of UFG and FFG samples were analyzed using a laser particle size analyzer BT-9300S (Bettersize Instrument Ltd., Dandong, China) and the results are shown in Fig. 1.It can be seen from Fig. 1 that the values of d 50, d 90 and d 95 were 40 μm, 93 μm and 116 μm, respectively for the UFG sample and 60 μm, 160 μm

The Critical Role of Pulp Density on Flotation Separation

2018年7月26日 In this study, the effect of pulp density on the separation of nickel-copper sulfide ore and serpentine was examined. The rheological measurements of both minerals and artificially mixed Micro-flotation tests were conducted on a XFGC flotation machine with a 40 mL cell at 1608 rpm (revolutions per minute). Before the mixed mineral fl

Control of clay minerals effect in flotation. A review

flotation performance and ore quality the negative effect of the clay minerals on flotation should be identified. The presence of clay minerals leads to problems, such as changing the froth stability, which are related to swelling behaviour, increase in pulp viscosity, overconsumption of reagents, slime coating and mechanical entrainment.

The effect of conditioning on Froth Flotation

2020年12月8日 Effect of Collector Concentration and Pulp Density -Varying concentration and pulp density led to some unexpected findings. The collector used in most of the tests was found to ionise only weakly and hence the reaction rate constant was adversely affected by increasing collector doses. The partial ionisation also resulted in the total lack of

A Brief Review of Pulp and Froth Rheology in Mineral

2019年10月16日 In mineral flotation, rheological problems have limited the efficient upgrading of low-grade and complex ores. Since pulp and froth rheology are deemed to play different roles in influencing the separation performance, in this , a brief review on pulp and froth rheology in flotation is provided, with an objective of developing a basic

OHYHORISXOS IORWDWLRQ Iopscience.iop

The flotation tests were performed in a Denver type pneumo-mechanical laboratory machine with a working chamber volume of 1dm3. Both the flotation pulp density and rotor speed for each flotation test was constant and amounted to 80 g / dm3 and 1850 rpm respectively. The RF55 (Reaflot-55)

Considering the effect of pulp chemistry during flotation

2017年11月1日 DOI: 10.1016/J.MINENG.2017.11.002 Corpus ID: ; Considering the effect of pulp chemistry during flotation on froth stability @article{Sheni2017ConsideringTE, title={Considering the effect of pulp chemistry during flotation on froth stability}, author={Nanji Sheni and Kirsten Claire Corin and Jennifer

Study on surface physical and chemical mechanism of

2023年3月3日 The particle size distribution of UFG and FFG samples were analyzed using a laser particle size analyzer BT-9300S (Bettersize Instrument Ltd., Dandong, China) and the results are shown in Fig. 1.It can be seen from Fig. 1 that the values of d 50, d 90 and d 95 were 40 μm, 93 μm and 116 μm, respectively for the UFG sample and 60 μm, 160 μm

The Critical Role of Pulp Density on Flotation Separation

2018年7月26日 In this study, the effect of pulp density on the separation of nickel-copper sulfide ore and serpentine was examined. The rheological measurements of both minerals and artificially mixed Micro-flotation tests were conducted on a XFGC flotation machine with a 40 mL cell at 1608 rpm (revolutions per minute). Before the mixed mineral fl

EFFECTS OF VARIED PROCESS PARAMETERS ON FROTH

flotation rate, and pulp density [15]. Therefore, this research aimed to characterize Itakpe iron ore, investigate the effects of varying collectors, particle sizes, and pH values on froth flotation efficiency and also establish the best process parameters that yield optimal recovery. 2. METHODOLOGY

Online Superficial Gas Velocity, Holdup, and Froth Depth

2022年3月31日 In flotation process, the efficiency and selectivity depend on mineralogy, particle size distribution and liberation, reagents added, mixing, and particle coverage. However, the kinetics of particle recovery is highly dependent on cell hydrodynamic and circuit configuration and operational strategy. Controlling froth depth and gas flow rate,

institute of quarrying malaysia

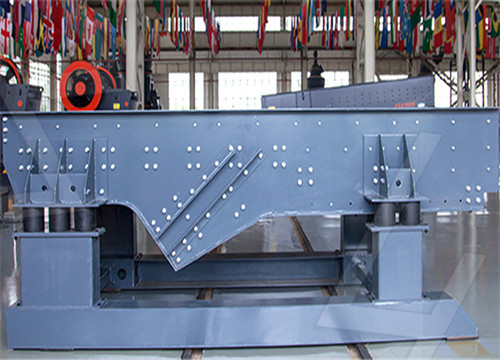

جزء من كسارة أداة

معدات تكسير الصخور للعثور على الذهب

crushing in uae-stone crushing plant uae

أجزاء من الحديد محطم خام

طحن سكاكين الصب حسب الطلب

diagram grinding equipment

مركز طحن الأسمنت

مطاحن الاعلاف الكهربائية مصر

iron ore classification process

special equipment for cnc polystyrene machine with high output

المغاسل آلة تنظيف متجر آلة الجاف

腋下是那里-๑۩๑ 私密處保養好物

crusher machine capacity

نموذج عمل كسارة الحجر

alat pemecah batu hammermill

موردي الخرسانة المسحوقة في الجنوب الشرقي

صور انواع مسدسات الطاحونه السبشل 5 طلقات

isa mill in canada copper plant as regrinding

مصنعي مصنع الرمل فارك في الصين

حيث لشراء آلات طحن

machine grind the iron

للبيع آلة عمل أنغولا

مطاحن المطرقة عالية السرعة 2 الطحن الجاف

أجزاء كسارة الصياجي ووظيفتها

coal quarrying crusher equipment

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20