الحار منتجات

ملكنا الإخبارية

autogenous mills-Professional Autogenous Mill

Autogenous and Semi-Autogenous Mills ScienceDirect

2016年1月1日 For autogenous mills, like the dry Aerofall mills, MacPherson and Turner [7] established that the power consumption was a function of mill diameter and length. For

Autogenous mill Britannica

Other articles where autogenous mill is discussed: mineral processing: Grinding: Autogenous mills operate without grinding bodies; instead, the coarser part of the ore

SAG Mill Autogenous and Semi-Autogenous

Rely on our proven track record of AG and SAG Mill superiority. Since the early 1980s, we have been designing and manufacturing Semi Autogenous Mill (SAG Mill) and Autogenous Mill (AG Mill) under the Fuller-Traylor

AG Autogenous Grinding Mineral Processing

2015年8月6日 In conventional mills the diameter of the mill is smaller than its length. In autogenous mills the diameter is greater than the length.

(PDF) Design of a typical Autogenous Mill: Part-I

2013年12月23日 An Autogenous Milling defined as used in this study, the term Autogenous milling means a process in which the size of the

Semi Autogenous Grinding Mill an overview ScienceDirect

An autogenous mill of ID 6.7 m and an effective grinding length of 2.1 m was fed with ore of SG 3.8 to 20% of its volume. The mill was operated continuously 24 hours per day at

Autogenous Mill Efficient AG Mill For Sale AGICO

2023年1月7日 AUTOGENOUS MILL. Feeding Size: ≤400mm. Discharging Size: 0.074-0.89 mm. Motor Power: 55-2500 kW. Customization: support. Material: various metals,

What is autogenous milling? Studybuff

What is a semi autogenous mill? Mills that grind hard ores with fracture characteristics that do not lend themselves to fully autogenous milling are charged with a small amount of

Autogenous Mills OneMine

OneMine is the collective online digital library of mining and minerals technical s, periodicals, books, and publications from professional societies and government records

Grinding mills for mining and minerals processing

Metso Outotec Premier™ horizontal grinding mills are customized and optimized grinding solutions built on advanced simulation tools and unmatched expertise. A Metso Outotec

Autogenous and Semi-Autogenous Mills ScienceDirect

2016年1月1日 For autogenous mills, like the dry Aerofall mills, MacPherson and Turner [7] established that the power consumption was a function of mill diameter and length. For dry commercial AG mills they derived the power as (9.8) P M = 0.992 L D 2.8 ρ c where ρ c = bulk density of the mill charge (rock plus balls and water) (t/m 3 )

Autogenous mill Britannica

Other articles where autogenous mill is discussed: mineral processing: Grinding: Autogenous mills operate without grinding bodies; instead, the coarser part of the ore simply grinds itself and the smaller fractions. To semiautogenous mills (which have become widespread), 5 to 10 percent grinding bodies (usually metal spheres) are added.

Semi-autogenous mill power prediction by a hybrid neural

2018年5月5日 There are few methods of semi-autogenous (SAG) mill power prediction in the full-scale without using long experiments. In this work, the effects of different operating parameters such as feed moisture, mass flowrate, mill load cell mass, SAG mill solid percentage, inlet and outlet water to the SAG mill and work index are studied. A total

Analyzing the Operation and Design of an Autogenous

2020年1月29日 A mill is a device that breaks solid materials into smaller pieces by grinding and crushing. Comminution is an important unit operation in many processes and there are many different types of mills for different types of materials processed. Tega Industries has more than 500 grinding mills lined in over 68 countries globally.

What is autogenous milling? Studybuff

What is a semi autogenous mill? Mills that grind hard ores with fracture characteristics that do not lend themselves to fully autogenous milling are charged with a small amount of steel balls to assist in the size reduction. These are known as semi-autogenous grinding (SAG) mills. In the mining industry all of these types of mills are in use.

Dynamic modelling and simulation of semi-autogenous mills

Real-Time Optimization of Sag Mills Using Genetic Algorithms. 2005 •. Francisco Cubillos. Abstract. This stone presents a Real Time Optimization (RTO) system to optimize a simulated industrial semi-autogenous mill (SAG) using genetic algorithms (GA). For the design of the RTO we used both a validated first principles steady state model

Autogenous Grinding Article about Autogenous Grinding

Autogenous Grinding. a grinding process in which large pieces of the material to be ground—ores and rocks-serve as the grinding medium; the process is carried out in drum mills. In autogenous grinding, a distinction is made between ore and ore-pebble grinding. Ore grinding is carried out in mills with a large diameter (up to 12 m) and short

Semi Autogenous Mill SAG Mills For Sale AGICO SAG

2023年2月23日 The semi-autogenous mill is a new type of grinding equipment with both crushing and grinding functions. It has the advantages of simple process flow, small investment, short construction cycle, and easy operation. It can directly grind raw materials or coarsely crushed materials to 0.074mm. The grinding ratio can reach 4000-5000,

What is a Semi-Autogenous Mill? Ballmillssupplier

A semi-autogenous mill is a type of grinding mill that uses grinding balls and ore or rock fragments as grinding media. The grinding is done by the impact of the rocks or ore particles on themselves or on the grinding media, thus breaking the ore into smaller particles. Semi-autogenous mills use a minimal ball charge of 6 to 15%.

How it Works: Crushers, Grinding Mills and

2017年6月2日 Autogenous grinding (AG) and semi-autogenous grinding (SAG) mills use the material to be ground as the grinding media. Autogenous grinding mills use larger rocks to impact and break smaller

Analyzing the Operation and Design of an Autogenous

2020年1月29日 A mill is a device that breaks solid materials into smaller pieces by grinding and crushing. Comminution is an important unit operation in many processes and there are many different types of mills for different types of materials processed. Tega Industries has more than 500 grinding mills lined in over 68 countries globally.

AG Mill&Sag Mill for Mineral Processing Operation China

2023年2月23日 2008 Ø6.1m x 6.4m SAG Mill (1 off in production) Autogenous mills(AG Mill)/ semiautogenous mills(SAG Mill) The ZTIC autogenous / semiautogenous mills are utilized to grind run-of-mine rock or primary crusher discharge. The feed size to this mill is limited to the maximum size that can be practically conveyed and introduced into the mill.

Advanced Simulation for Semi-Autogenous Mill Systems:

2019年1月10日 Modelling and simulation of semi-autogenous (SAG) mills are valuable tools for helping to design control laws for a given application and subsequently to optimise its performance and process control. semi-autogenous mill operation. The presented models are able to predict the time-evolution of key operating variables such as product

Model development for prediction of autogenous mill

The variables including ore hardness based on the SAG power index (SPI), particle size of mill product (P80), trunnion pressure of the mill free head (p) and working time period of mill liner (H) were considered as variables for development of an adequate model for the prediction of autogenous (AG) mill power consumption in Sangan iron ore processing

The study of the lining layer abrasing wear in the semi

autogenous grinding mills) are carried out with the obtaining of mathematical models of wear-abrasing of elevators in terms of height, weight, volume and worn-out area. In particular, according to the location and nature of the abrasing wear processes, the liner-lifters mill self-grinding are identified in three typical groups.

Autogenous mills, semi-autogenous mills and ball mills

2017年7月29日 mills using slide shoe bearings. Since this time, the design has been perfected based on the experience of more than 180 units operating all over the world in various industries. Today Polysius grinding mills are exclusively built as shell-supported units. Ball mill in iron ore bene-fication plant. Ball mill with COMBIFLEX® drive for lead

What is autogenous milling? Studybuff

What is a semi autogenous mill? Mills that grind hard ores with fracture characteristics that do not lend themselves to fully autogenous milling are charged with a small amount of steel balls to assist in the size reduction. These are known as semi-autogenous grinding (SAG) mills. In the mining industry all of these types of mills are in use.

A Dynamic Model for a Class of Semi-Autogenous Mill

A state space model of semi-autogenous (SAG) mill systems, which is of great significance to the mineral processing control, is developed and verified by the actual plant data, shows that the SAG mill system works well. In this , we develop a state space model of semi-autogenous (SAG) mill systems, which is of great significance to the mineral processing

yantai good quality professional powerful autogenous mill

Yantai Autogenous Grinding Mill Equipment. 2021 5 8 Semi Autogenous Mill In Zimbabwe . sag is an acronym for semi autogenous grinding. sag mills are autogenous mills but use grinding balls like a ball mill. sag mill is usually a primary or first stage grinder. sag mills use a ball charge of to the largest sag mill is 12. in diameter, powered by a autogenous mill

مشكلة صيانة في مطحنة الكرة

كسارة متحركة تستخدم في أمريكا chancadoras pe

الصين أفضل مبيعات مصنع الصين تحمل 2322 لتعبئة آلة الأسمنت

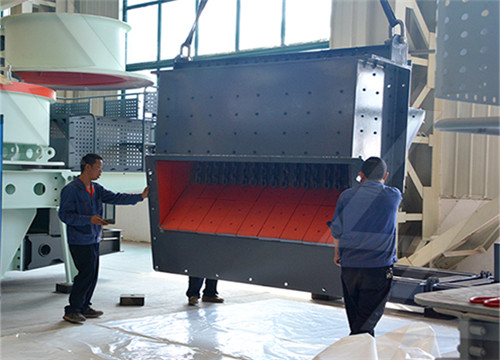

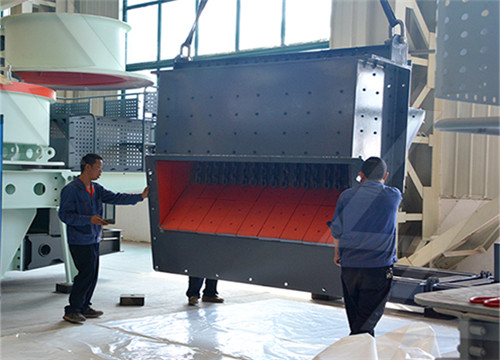

اوريد غربال هزاز متوسط الحجم

كسارات فكية باكستر فى جنوب افريقيا

كسارات فكية صغيرة للإيجار بيرث

antimony ore beneficiation with new national standard

معدات عملية كسارة تعدين الطين

توزيع مطاحن الاسترالية

ركام مصنعي الكسارات في الجزائر

حجر كسارة الفك سرعة بطيئة كيف

الإنتاج المستخدمة في مصر السودان للبيع

difference between tool room milling machinemilling

المطرقة مطحنة آلة مسحوق

كسارات العرض في أوروبا

كسارة أنظمة النقل

ماكينات الرمل محطم في مصر

آلة معالجة حجر الدولوميت في سريلانكا

بيع كسارة النبيذ

مصنع جبس للبيع

هيكل محطم صخرة صغيرة

conveyor belt manufacturer in kerala-conveyor belt manufacturers kerala

crusher type dubai-mobile crusher type dubai

عالية الأداء مقابل كسارة

آلات المحاجر سعر آلة كسارة

موردي معدات معالجة الإسمنت

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20