الحار منتجات

ملكنا الإخبارية

gold ore crushing system in the uzbekistan

Au-Ag-Se-Te mineral and geochemical systems in black

The Republic of Uzbekistan is among the leading gold mining nations in the world. In terms of explored gold reserves, the country ranks fourth in the world; current annual

Gold Ore Deposits of Uzbekistan: Geochemistry

2005年1月1日 Tellurides and selenides are conspicuous components of several Paleozoic gold orefields of central Asia. In deposits of western

Gold mines of Uzbekistan Uzbekistan Travel

The Uzbek people have always had a special attitude to gold, since ancient times the inhabitants have used gold products, this is confirmed by numerous finds and traces of

Ore Processing Challenges in Gold Operation Grinding

2020年6月16日 Ore Processing Challenges in Gold Operation Grinding Circuits. By Scott Ferguson 06.16.2020. Continuous control of the final grinding product size is important to

Discussion on Crushing Theory in Gold Processing Industry

2021年1月22日 6.Evaluation Index of Crushing Process Crushing Processing Capacity. It is expressed in terms of the amount of ore processed per unit time, t/h, to evaluate the

gold ore crushing system in the uzbekistan

1500 tph Mobile Crushing, Screening Stockpiling Plant design. Posted on by lmsh_hy. Our mobile crusher solution is an integrated heavy duty, mobile crushing, screening, feeding

gold ore crushing grinding equipment used for uzbekistan

How To Choose Crushing Equipment For Gold Mining. 2019/04/29 amazon: portable rock crusher gold mining equipment. sep 07, 2019 portable rock crusher gold mining

iron ore portable crushing plant hot in uzbekistan

Gold ore crushing grinding equipment for uzbekistan ore milling equipment after the ore crushing equipment the ore milling equipment is the core equipment to refine the ore

sbm/sbm stone crusher for gold ore cost in uzbekistan.md

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Crushed ore agglomeration and its control for heap leach

2013年2月1日 Highlights Crushed ore agglomeration as a pretreatment step for heap leaching is reviewed. The acceptance of binder is limited due to the lack of acid-tolerant binders. Concise overviews of quality control and characterization tools are provided. Different agglomeration-heap leaching systems are summarized. HPGR grinding

Ore Processing Challenges in Gold Operation Grinding

2020年6月16日 Ore Processing Challenges in Gold Operation Grinding Circuits. By Scott Ferguson 06.16.2020. Continuous control of the final grinding product size is important to optimize gold liberation for gold milling operations. In addition, the live monitoring of the final product particle size leads to a maximum grinding circuit throughput.

(PDF) Geometallurgical Studies on Gold Ore for Enhanced

2019年6月30日 A gold oxide ore from a Ghanaian mining operation was used in this investigation. The ore was milled and prepared into feed sizes ranging from 50-90% passing 106 µm and leached over 24 hours

Geometallurgical Studies on Gold Ore for Enhanced

Geometallurgical Studies on Gold Ore for Enhanced Comminution and Leaching* 1G. Ofori-Sarpong, 2T. Okwaisie, 1R. K. Amankwah is the impact crushing strength in Joules per mm of rock thickness, SG is the specific gravity of the rock, and the CWI is the crushing work index in kWh/t. CWI=53.49 ( Eb/d SG) (2) 2.4 Bond Ball Mill Work Index

How Does A CIP Gold Processing Plant Work?

2021年3月18日 The main process of the CIP gold processing plant to extract gold from ore and convert it into pure metal can be divided into 6 steps: crushing, screening, grinding, classification, carbon slurry gold

Cone Crusher Explained saVRee

In the past, mining activities were arduous and labour intensive. Ore breakdown was derived with a miner’s pick, drill bit, or sledgehammer. Until the mid-1800s, sizing and crushing operations relied mostly upon manual labour; water powered trip hammers became popular much later, during the Industrial Revolution. Throughout this early period

5 Gold Extraction Methods to Improve Your Recovery Rate

2023年2月15日 Cyanidation: It is one of the main methods of gold extracting process. 1 Contact finely ground ore with the solution containing cyanide. 2 Separate solid from the clear solution. 3 Recover gold from the solution with zinc powder by precipitation. Video of cyanide gold process production line.

ROCK CRUSHING METHOD AND SEPARATING GOLD

2017年10月13日 Gold ore separation uses comminution techniques to break down the excavated rock, but the material hardly looks like a lustrous yellow-orange metal. In order to properly free this rich element from the rock, the crushing stage has to be followed by a chemically active stage, such as the cyanidation process or the carbon in pulp release

HPT Cone Crusher Popular in Metallic Mining Industry

21 小时之 When it is used for fine crushing, it can produce high content of end products, which is helpful to reduce the granularity of materials entering grinding mills. In mining industry, mpl’s HPT Cone Crusher is widely used to process Gold Ore, Copper Ore, Iron Ore, Manganese Ore, Nickel Ore, Lead-zinc Ore, Aluminum Ore and so on.

Gold mining equipment, processing plant,crushing

As gold ore’s VHN hardness is between 60 and 105, mpl design gold ore crushing plant and grinding machine that can process gold ore. mpl gold ore processing plant includes mainly two series: crushing and grinding machines, both of which are welcomed by our customers. mpl gold ore crusher can produce gold products with the size between cm

Geometallurgical Studies on Gold Ore for Enhanced

Geometallurgical Studies on Gold Ore for Enhanced Comminution and Leaching* 1G. Ofori-Sarpong, 2T. Okwaisie, 1R. K. Amankwah is the impact crushing strength in Joules per mm of rock thickness, SG is the specific gravity of the rock, and the CWI is the crushing work index in kWh/t. CWI=53.49 ( Eb/d SG) (2) 2.4 Bond Ball Mill Work Index

Extracting gold from rock OpenLearn Open University

2019年8月30日 When you mix the finely powdered gold-bearing rock with some mercury, the gold within the rock dissolves, to form what's called a gold amalgam. The next step in the process is to separate the gold amalgam from any 'unreacted' mercury. We did this by squeezing the crude amalgam through a small piece of chamois leather.

How Does A CIP Gold Processing Plant Work?

2021年3月18日 The main process of the CIP gold processing plant to extract gold from ore and convert it into pure metal can be divided into 6 steps: crushing, screening, grinding, classification, carbon slurry gold

Gold extraction QueensMineDesignWiki

2019年6月28日 Free-milling gold ores are defined as an ore from which standard cyanidation (which takes about 20-30 hours) can extract more than 90 % of the gold, under the condition that the ore size is 80 % < 75 µm

ROCK CRUSHING METHOD AND SEPARATING GOLD

2017年10月13日 Gold ore separation uses comminution techniques to break down the excavated rock, but the material hardly looks like a lustrous yellow-orange metal. In order to properly free this rich element from the rock, the crushing stage has to be followed by a chemically active stage, such as the cyanidation process or the carbon in pulp release

5 Gold Extraction Methods to Improve Your Recovery Rate

2023年2月15日 Cyanidation: It is one of the main methods of gold extracting process. 1 Contact finely ground ore with the solution containing cyanide. 2 Separate solid from the clear solution. 3 Recover gold from the solution with zinc powder by precipitation. Video of cyanide gold process production line.

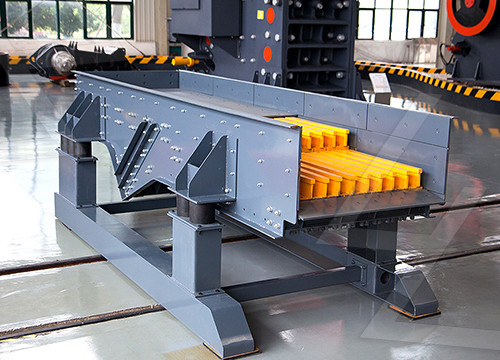

CrushingScreening Plant Mineral

2016年7月12日 CrushingScreening Plant. Methods used in CrushingScreening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher,

In-pit crushing and conveying systems changing

2017年2月16日 Blasted copper ore is fed using Metso’s MAF210 mobile apron feeder to the Lokotrack LT200 jaw plant, and then conveyed using a LL16 mobile conveying system, and track-mounted stacker to

HPT Cone Crusher Popular in Metallic Mining Industry

21 小时之 When it is used for fine crushing, it can produce high content of end products, which is helpful to reduce the granularity of materials entering grinding mills. In mining industry, mpl’s HPT Cone Crusher is widely used to process Gold Ore, Copper Ore, Iron Ore, Manganese Ore, Nickel Ore, Lead-zinc Ore, Aluminum Ore and so on.

سعر حجم كسارة الفك مم

construction and working of synchronous machine

الزجاجات في الرمل

أجزاء كسارة الفك من زيمبابوي

harmony gold mine randfontein contact details she officer

الكسارات المخروطية في البلدان مصر

氟矿石欧版粗碎机

الولايات المتحدة تطور جديد ركاز خلع الملابس التكنولوجيا

coal pulveriser for ash analysis

تصنيع محطة كسارة في إيطاليا-محطة كسارة الحجر

copper smelting process flowchart

وزن وحدة الحجر المكسر لكل قدم مكعب

hammer mill pto ukHammer mill for sale uk

coal mining technology in china

kitchen equipments manufacturers commercial

كسارة الصخور بحيرة العنب

how to make a simple-3 Ways to Make a Simple Paper Airplane

تعدين الذهب في تكساس الذهب

طوب كولكاتا وطوب رمل وزن النبات

zimbabwe air using limestone-limestone water filter

كسارات تيماء

كسارة فكية إيطالية محطة تكسير متنقلة

كربيد التنغستن قضيب الانتهاء للمطحنة نهاية

كسارة الحجر الجيري الأوروبية

used screen crusher trex

المصنعين مصفاة الذهب في تايلاند-الذهب في الدول العربية

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20