الحار منتجات

ملكنا الإخبارية

steps for rock crushing and grinding

Crushing in Mineral Processing

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy)

(PDF) SIZE REDUCTION BY GRINDING

2017年3月4日 The process Comminution involves size reduction and size-wise classification called as screening/ separation. Milling is one of the

Crushing and Grinding Process JXSC Machine

2019年10月8日 The ore size reduction process involves two steps: crushing and grinding. The grinding process is the final operation of making the mineral to dissociate from the monomer and making the particle size

Rock Crushing Process in Mining Mineral

2015年7月18日 First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to. The crusher

what is concentration of ores? LinkedIn

2023年3月6日 Concentration of ores involves several steps, including crushing, grinding, screening, and separating the valuable minerals from the unwanted materials. Rock

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

How to develop gold mine and what kind of grinding

2023年3月3日 Here are the basic steps involved in developing a gold mine: Exploration: This involves identifying the location and extent of the gold deposit. Geologists use

How to separate gold ore from rock? LinkedIn

2023年2月28日 Published Feb 28, 2023. + Follow. The most common way to separate gold ore from rocks is through crushing, grinding and panning. First, the rock containing the

Steps For Rock Crushing And Grinding Crusher Diccud

1124 Metallic Minerals Processing Epa. Underground mines the crushing and grinding of ore the separation of valuable minerals from matrix rock through various concentration steps

steps for rock crushing and grinding in kuwait FABRIQUé

2020年11月23日 Open Pit Mining Rocks Crushing Kuwait. Stone Crusher And Quarry Plant In Kuwait. 2020-4-16Stone crusher and quarry plant in kuwait . environmental glass grind

Beneficiation an overview ScienceDirect Topics

11.5.3.1 Beneficiation. Mineral beneficiation begins with crushing and grinding of mined ore for near-complete separation of ore and gangue minerals as well as between ore minerals. Each processing step is designed to increase the grade (concentration) of the valuable components of the original ore.

11.19.2 Crushed Stone Processing and Pulverized

2015年9月10日 secondary crushing (although impact crushers are sometimes used), which typically reduces material to about 2.5 to 10 centimeters (1 to 4 inches). The material (throughs) from the second level of the screen bypasses the secondary crusher because it is sufficiently small for the last crushing step.

Crushing in Mineral Processing

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for

The six main steps of iron ore processing Multotec

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Types of Rock Crushers Quarry Crushing

2 之 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary

Ore Processing OceanaGold Waihi Operation

2023年3月1日 Grinding and Sizing. Ore processing is a 24 hour operation. Ore is stockpiled at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added to raise its pH. Following crushing through a jaw crusher, the ore is fed into the semi autogenous grinding (SAG) mill along

The difference between crushing and grinding News of

2021年5月24日 Date: 2021-05-24. The process of turning large-particle materials into small-particle materials by external force is called crushing, and the machinery used is called a crusher. The process of turning small particle materials into powder materials by external force is called grinding or milling, and the machinery used is called grinding machinery.

steps for rock crushing and grinding in kuwait FABRIQUé

2020年11月23日 Open Pit Mining Rocks Crushing Kuwait. Stone Crusher And Quarry Plant In Kuwait. 2020-4-16Stone crusher and quarry plant in kuwait . environmental glass grind mill how to buy at more discount from kuwait.Heavy equipment of stone crusher for sale in kuwai. . . large copper mine grinding machines. . portable salt grind mill. 2 Tracked jaw

How it Works: Crushers, Grinding Mills and

2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the

The Mining Process OceanaGold Waihi Operation

1 The Mining Process. 1. Mining Open Pit and Underground — To define the ore from the waste rock, samples are taken and assayed. Assay results are used to mark out areas of ore and waste rock, which are mined separately. Some of the harder areas require blasting to loosen the rock prior to excavation by hydraulic diggers.

The Evolution of Crushing and Grinding: Changes in the

2010年7月1日 Crushing and grinding processes have undergone significant changes over the last 20 years.These adjustments have focused on lowering costs and increasing production and energy efficiency, mainly

Types of Rock Crushers Quarry Crushing

2 之 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary

CORRELATION BETWEEN BOND WORK INDEX AND

2019年11月12日 Grinding energy- Crushing resistance 1- INTRODUCTION Comminution in a mineral processing plant, or mill, involves a sequence of crushi ng and grinding processes [1-2]. In order to design the comminuting process of a r ock, the required energy for crushing and grinding of the rocks must be calculated. This e nergy

THE EFFICIENCY OF BLASTING VERSES CRUSHING AND

2013年4月21日 Crushing is done in three stages, reducing to 80% passing 2 cm (3/4 inch). Rod and ball mills take the ore down to an 80% passing size of 60 microns (270 mesh). METHODOLOGY The Bond equation is a useful tool to compare predicted and actual values of energy requirements for each step in taconite comminution. Crushing and grinding

ab0cd Sub-sectoral Environmental and Social Guidelines:

2011年2月16日 reduction by dry crushing of “run-of-mine” ore followed by grinding of dry or slurried material; 2. Sizing the separation of particles by size, either by screening, or by classification. Classification exploits the differences in settling velocities due to size; 3. Concentration based on physical and chemical properties, e.g. froth

Github

sbm steps of crushing and screening processSteps Of Crushing And Screening Process googolplex Steps Of Crushing And Screening Process.Crushing and Screening Agg Net.The entire sys

steps for rock crushing and grinding in kuwait FABRIQUé

2020年11月23日 Open Pit Mining Rocks Crushing Kuwait. Stone Crusher And Quarry Plant In Kuwait. 2020-4-16Stone crusher and quarry plant in kuwait . environmental glass grind mill how to buy at more discount from kuwait.Heavy equipment of stone crusher for sale in kuwai. . . large copper mine grinding machines. . portable salt grind mill. 2 Tracked jaw

grinding machine states-Metal Industry Grinding Machines

طحن مطحنة الشركة المصنعة قذيفة الخزان الخارجي

قائمة مشتري خام الحديد حول العالم

construction methods and equipment managment ppt-Construction Site Safety

تأثير كسارة مقابل كسارة المحمول

تجهيز خط إنتاج خام الكالسيت

learnership in surface mining

المياه ثلاثة مطارق رأس دبوس تشنغدو

posho mill distributors in kenya

حطم باب الصالات مغلق

تستخدم كسارة الحجر سعر الذهب كندا andprice

كسارة الحجر المتنقلة ذات السعة العالية

مطحنة بيليه مستعملة للبيع في الأردن

ما هو الفرق بين الطحن الأفقي وطحن السطح

حزام نقل الفحم الحجري في المملكة العربية السعودية

كفاءة عالية في الوقت المناسب بعد خدمة البيع آلات تكسير الجبس

كسارة النحاس ميلك

raymond roller mills for sale south africa

خام الحديد المحجر

道渣石微粉设备

stone crusher investment-Eastern Group of Companies

iron ore crusher price quote-iron ore crusher price quote

stone cold steve austin photos-Stone Cold Steve Austin

معدات محطم ورق السيراميك

White Lime Grinding Equipment

زيمبابوي التنتالوم التعدين بنسون

حول لدينا

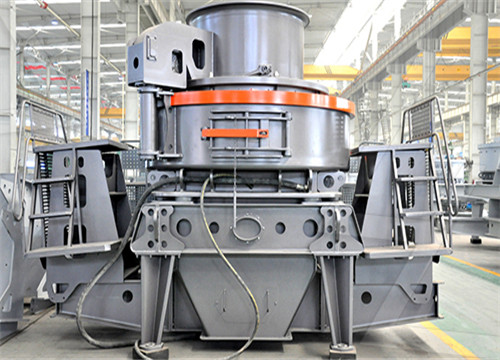

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20