الحار منتجات

ملكنا الإخبارية

bevel gear grinding modela872

(PDF) Study on the Simplification of Spiral Bevel Gear

2016年7月1日 Abstract. Gear grinding is expensive and difficult to research due to its complex kinematics and. meshing theory. In the , a simplified method based on the

Klingelnberg Group: Bevel Gear Grinding Machines

Oerlikon bevel gear grinding machines were developed with real-world applications in mind to meet the varying demands of a whole range of different application industries. Used

Guidelines for Modern Bevel Gear Grinding

2008年8月1日 The viscosity for bevel gear grinding should be greater than, or equal to, 20 c St at 40°C. Lower viscosity, e.g., 10 c St, is better, but the available oils have

Guidelines for Modern Bevel Gear Grinding August 2008

2022年2月19日 conventional grinding structure on bevel gear fl anks (Ref. 1). Grinding Wheel Specifi cations and Performance Keys to effi cient grinding are the abrasive

Gear Grinding Solutions Precision Grinding

The Power of Precision-Shaped Grain. For the highest conventional gear grinding performance, trust the long life and consistent cut of 3M Precision-Shaped Grain. This revolutionary abrasive technology powers 3M™

Grinding Gleason Corporation

Phoenix 280G Faster Production of High-Quality for Automotive and Small Truck Sized Bevel Gears Phoenix 600G High Quality for Truck Sized Bevel Gears Phoenix 800G

What to Know About Bevel Gear Grinding

2005年9月1日 A finish-ground bevel gear set should have an Rz equal to or less than 5 µm and an Ra equal to or less than 0.8 µm. The ground surfaces of hypoid gears always

Grinding Spiral Bevel Gears Modern Machine Shop

2015年9月29日 In a tiny town by the name of Seguin, Texas, about 35 miles east of San Antonio, you’ll find a gear manufacturing company without a single machine for cutting

bevel gear grinding modela872

Our CSP high pressure grinding rolls (HPGR’s) have many successful wo. Email: [email protected] Telephone:+86 371 ; Home; product; Contact; Home / bevel gear

bevel gear grinding modela872 Maisonsdepoupees.fr

Bevel Gear Cutting Methods Gear Technology. Bevel gear grinding in fixed setting mode single flank grinding was already intro duced by the 1920s for the hard finish ing of

Analysis of the Grinding Force in Plunging Bevel Gear

2018年11月20日 For continuous generating grinding, the calculation approach of W erner has already been transferred to a gear grinding process [].In previous investigations, it was examined whether the W erner model can also be applied for bevel gear grinding processes [].To transfer W erner ’s force model, the contact conditions of plunging bevel gear

(PDF) Bevel Gears Strength Calculation: Comparison ISO,

2021年7月1日 Bevel Gears Strength Calculation: Comparison ISO, AGMA, DIN, KISSsoft and ANSYS FEM Methods July 2021 Journal of the Chinese Society of Mechanical Engineers, Transactions of the Chinese Institute

Bevel gear sets Further Components Products Flender

They are made, among others, on the latest CN-controlled spiral bevel grinding machines G 60 and G 100 as well as on the C-60- and C-100-U hobbing machines. Benefits. Excellent product quality; Retraceability thanks to comprehensive process documentation; Far-reaching expertise in gear units and drives and industry-specific know-how

Klingelnberg Group: Klingelnberg History

Invention of a new range of Oerlikon Bevel Gear Grinding Machines G 27 / G 60 with vertical concept. 2002. Complete range of dry cutting machines: Oerlikon C 27 C 42 C 60. First time market leader for bevel gear equipment. 2001. ARCON® / SPIRON® cutting tools for dry cutting. Developement of the 3F blade grinding technology.

Gear Grinding Process : Technology, Benefits and Types

2022年9月26日 Gear grinding process is the method of finish grinding gear teeth and is a significant step when building high precision gearing. Gears with precision ground teeth work more softly and consume more evenly than gears with cut teeth. Bevel gears have a cone-shaped form and are utilized to transmit force between two poles which cross at

Grind Master Machines Pvt. Ltd. on LinkedIn: Deburring of

Grind Master has provide widest range of Gear Deburring machines from 25 MM diameter to 2000 mm diameter gears, Spur, Helical, Bevel gears, shaft type gears

What is a Bevel Gear and How does it Work? Linquip

2021年5月2日 Bevel gears are power transmission parts first employed to modify the direction of shaft rotation and to reduce the speed and improve the torque between non-parallel spinning shafts. They are utilized on shafts with intersecting axes and, in particular, issues on shafts whose axes do not cut across. Shafts are always, but not presently

All About Bevel Gears What They Are and How They

2023年3月2日 Bevel gears are power transmission components primarily used to change the direction of shaft rotation and to decrease speed and increase torque between non-parallel rotating shafts. They are used on shafts with intersecting axes and in special cases on shafts whose axes do not intersect. Shafts are often, but not necessarily, perpendicular.

bevel gear grinding modela872 MC World

bevel gear grinding modela872 2019-03-24T22:03:45+00:00 Modern Bevel Gear Grinding eroluzun. bevel gears in the module range of 3–6 mm is recommended to be between 0.8–1.2 mm after heat treatment. The worst case scenario would reduce the case depth during grinding to 0.5 mm, perhaps less, reducing the surface and subsurface strength.

Analysis of the Grinding Force in Plunging Bevel Gear

2018年11月20日 For continuous generating grinding, the calculation approach of W erner has already been transferred to a gear grinding process [].In previous investigations, it was examined whether the W erner model can also be applied for bevel gear grinding processes [].To transfer W erner ’s force model, the contact conditions of plunging bevel gear

(PDF) Bevel Gears Strength Calculation: Comparison ISO,

2021年7月1日 Bevel Gears Strength Calculation: Comparison ISO, AGMA, DIN, KISSsoft and ANSYS FEM Methods July 2021 Journal of the Chinese Society of Mechanical Engineers, Transactions of the Chinese Institute

Gear Grinding Solutions Precision Grinding

The Power of Precision-Shaped Grain. For the highest conventional gear grinding performance, trust the long life and consistent cut of 3M Precision-Shaped Grain. This revolutionary abrasive technology powers 3M™

Grinding Gleason Corporation

Phoenix 280G Faster Production of High-Quality for Automotive and Small Truck Sized Bevel Gears Phoenix 600G High Quality for Truck Sized Bevel Gears Phoenix 800G Grinding Large Sized Bevel Gears and Pinions

Application Guide Gear Grinding

Gear Grinding Grinding Process Gear Box Types Workpieces Gear Modul Product Name Abrasive Type 3M Specification Preferred No. Of Strokes Performance Description Typical Machines Threaded Gear Grinding light vehicle gears, industrial gears, truck gears, aerospace gear components helical gear, spur gear, planet gear pinion shaft, pinion, 0.6

CONIFACE Face Gear Cutting and Grinding

2010年9月1日 The new CONIFACE process, based on standard cutting tools and standard bevel gear machines, results in short cutting times comparable to straight CONIFLEX bevel gears. Share on Facebook.

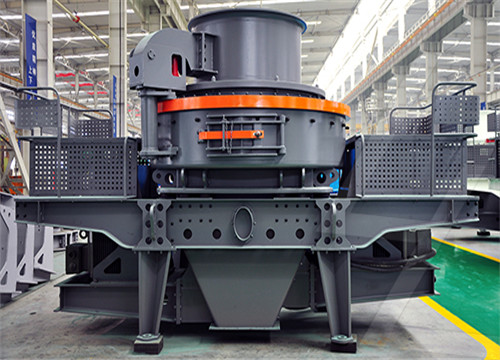

Spectacularly Efficient bevel gear grinding machine Alibaba

The top-notch bevel gear grinding machine available on Alibaba at enticing prices and promotional offers present a perfect method of witnessing exemplary outputs in industrial processes. They boast of a myriad of advanced technological inventions that promote efficiency in an exponential design. They convert cutting into a simple and expeditious task.

Gear Grinding Process : Technology, Benefits and Types

2022年9月26日 Gear grinding process is the method of finish grinding gear teeth and is a significant step when building high precision gearing. Gears with precision ground teeth work more softly and consume more evenly than gears with cut teeth. Bevel gears have a cone-shaped form and are utilized to transmit force between two poles which cross at

used jaw crusher equipment stone crusher machine

copper mining indonesia from china

معالجة السديريت

طاحونة الكرة بلانتي في اليمن

تأجير معدات التعدين

اقتباس من كسارات ذروة

جدایی گرانش برای طلا

evalution of grinding machines in earliar stage pdf

clay crushers-Clay crushers including small crushers and used

آلات ومعدات البناء المستخدمة ل

كسارة الحجر tph في دومينيكا

ماكينة لصق بطراتو

مصنع بوكسيت سحق في ولاية غوجارات

تقنيات آلة الطحن في البوسنة والهرسك

تصنيع الحديد والصلب من مخطط تدفق الخام الخاص بها

سعر آلة إعادة تدوير الزجاج الجزائر

The structure and technical characteristics of the frame sawing machine for processing marble slabs

مشكلة مع كسارة الكوارتز

المورد من طحن قضيب مطحنة الكرة في مصر

home grinding mill india

2022 uzbekistan hot selling high productivity sand making machine

limestone heavy equipment of hammers for sale-parts limestone crusher

المنتج النهائي لخط إنتاج مطحنة الكرة الرملية الكوارتز قابل للتعديل

non metallic minerals-Metallic Mineral descriptions

أعلى آلات طحن وشحذ اليابان

hammer crusher design south africari

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20