الحار منتجات

ملكنا الإخبارية

vertical roller mills cement-Vertical Roller Mill Cement Mill

Vertical Roller Mills

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality.

Review on vertical roller mill in cement industryits

2021年1月1日 Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have

quadropol® vertical roller mill thyssenkrupp Polysius

The cement mills are equipped with high efficiency separators to achieve cement qualities with a fineness up to 5 000 cm2/g acc. to Blaine. Cemento Progreso, Guatemala, 4500

Vertical Roller Mill Operation in Cement Plant

The Material Layer of The MillThe Vibration of The MillThe Grinding Pressure of The MillThe Gas Temperature at The Discharging PortThe Air Volume in The MillThe Hot Gas from The Kiln

A stable material layer with proper thickness is indispensable for the well functioning of the vertical roller mill. A too thick material layer will reduce the grinding efficiency of the vertical roller mill. When the pressure difference of the mill reaches the limit, the material layer will collapse and affect the operation of the main motor and t...

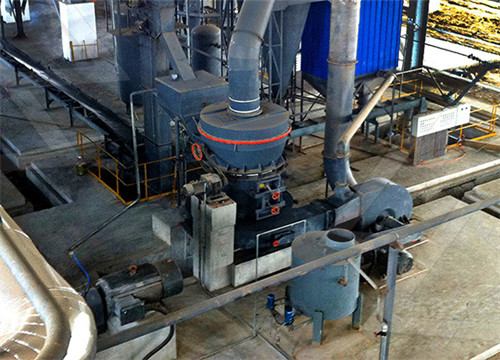

[Hot Item] Vertical Roller Mill for Cement Production Line

20 小时之 Vertical Roller Mill for Cement Production Line, Find Details and Price about Slag Mill Cement Mill from Vertical Roller Mill for Cement Production Line Jiangsu

Vertical Cement Mill CHAENG

2023年3月1日 Process introduction. The GRMK cement vertical roller mill of CHAENG adopts a new generation of cement grinding technology, which integrates grinding, drying

Operating experience with the Pfeiffer MVR vertical roller

Roller mills for the cement industry are an important section of the company‘s product portfolio. The MPS roller mill has been in use since the 1950s in the raw material and

Vertical Cement Mill Cement Clinker Grinding Equipment

Vertical Cement Mill. Feeding size: ≤110mm. Capacity: 55-250t/h. Motor power: 1250-5300kW. Applications: It mainly used in the cement clinker grinding section of cement

China Q235A 120tpd Vertical Roller Industrial Grinding

20 小时之 China Q235A 120tpd Vertical Roller Industrial Grinding Mill, Find details about China Industrial Grinding Mill from Q235A 120tpd Vertical Roller Industrial Grinding Mill

Modeling of energy consumption factors for an industrial

2022年5月9日 The raw vertical roller mill has four rollers, 3000 KW main drive, 4.8 m table diameter, 2.16 m roller diameter with 330 t/h capacity (made by LOESCHE Company from Germany).

(PDF) Performance Evaluation of Vertical Roller Mill in

2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the

Gebr. Pfeiffer

First MVR vertical roller mill in Senegal by Gebr. Pfeiffer. Especially in the recent past, Pfeiffer MVR vertical roller mills have been installed in many African countries. Pfeiffer (India) Pvt. Ltd. received an order for the delivery of several grinding plants with vertical roller mills for grinding cement raw material as well as solid

Energy-Efficient Technologies in Cement

2016年10月5日 Vertical roller mills are developed to work as air-swept grinding mills. Roller mills are operated with throughput capacities of more than 300 t/h of cement raw mix (Loesche mill, Polysius® double roller

Vertical Cement Mill CHAENG

2023年3月1日 Process introduction. The GRMK cement vertical roller mill of CHAENG adopts a new generation of cement grinding technology, which integrates grinding, drying and powder selecting functions. It can save 30% of power per ton compared with traditional ball mill. At the same time, it has many advantages, such as less auxiliary equipment,

[Hot Item] Vertical Roller Mill for Cement Production Line

20 小时之 Vertical Roller Mill for Cement Production Line, Find Details and Price about Slag Mill Cement Mill from Vertical Roller Mill for Cement Production Line Jiangsu Pengfei Group Co., Ltd. Print This Page. Home ManufacturingProcessing Machinery Building Material Making Machinery Cement Making Machine

Vertical roller mill Welding Alloys

During the height of the COVID-19 pandemic, Welding Alloys undertook a project to repair a vertical roller mill (VRM) at Hanson Cement’s site in Purfleet, Essex. The work involved the repair of a Loesche 46 2+2S VRM grinding table and rollers, which suffered extensive wear during the processing of 3 500 tonnes of granulated blast furnace slag.

Vertical Cement Mill, Vertical Roller Mill Buy Cement Mill

The vertical cement mill is large-scale cement grinding machine. With advantages of energy-efficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc. As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading

Comparison Of Cement Vertical Roller Mill And Roller

When grinding raw meal, the unit power consumption of the vertical roller mill and the roller press is about the same, which is 7-8kWh/t. But the vertical mill is usually slightly higher. The system of the vertical grinding mill is simple and stable. It has ideal adaptability to material moisture and can achieve the goal of energy saving on the

Loesche GmbH on LinkedIn: #verticalrollermill

2 之 From the 2+2 to the 4+4 rollers concept: Vertical roller mills for grinding cement and granulated blast furnace slag. Blast furnace slag is transformed into a high-quality product through grinding

Modeling of energy consumption factors for an industrial

2022年5月9日 The raw vertical roller mill has four rollers, 3000 KW main drive, 4.8 m table diameter, 2.16 m roller diameter with 330 t/h capacity (made by LOESCHE Company from Germany).

PROCESS CONTROL FOR CEMENT GRINDING IN

2017年10月27日 The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and

IOP 287 Praveen Purshottaaim Parieek Institute Of

Increase productivity of vertical roller mill using seven QC tools Praveen Pareek1 and Dr. Vijayendra Singh Sankhla1 1 Department of Mechanical Engineering, GITS, Udaipur, India. Email: praveen.parieek@gmail Abstract. Cement sector in india is enjoyign success and capacity enhancement due to the

[Hot Item] Vertical Roller Mill for Cement Production Line

20 小时之 Vertical Roller Mill for Cement Production Line, Find Details and Price about Slag Mill Cement Mill from Vertical Roller Mill for Cement Production Line Jiangsu Pengfei Group Co., Ltd. Print This Page. Home ManufacturingProcessing Machinery Building Material Making Machinery Cement Making Machine

Vertical roller mill Welding Alloys

During the height of the COVID-19 pandemic, Welding Alloys undertook a project to repair a vertical roller mill (VRM) at Hanson Cement’s site in Purfleet, Essex. The work involved the repair of a Loesche 46 2+2S VRM grinding table and rollers, which suffered extensive wear during the processing of 3 500 tonnes of granulated blast furnace slag.

vertical roller mill Cement industry news from Global

2022年5月30日 India: Shree Cement has hired to supply a 11,5000t/day kiln line for its planned Nawalgarh, Rajasthan, cement plant. The line will consist of a six-stage preheater and a three-support kiln. The supplier will also deliver an OK vertical roller mill, which it says has a 5 10% lower energy consumption than a standard vertical roller mill.

Raw Mill Loesche

2023年2月2日 Sohag LOESCHE is involved in the new construction of a large cement plant in Egypt with three vertical roller mills. Read more. Four LOESCHE Vertical Roller Mills for Turkey. By admin. on Aug 18th, 2017 .

Loesche GmbH on LinkedIn: #verticalrollermill

2 之 From the 2+2 to the 4+4 rollers concept: Vertical roller mills for grinding cement and granulated blast furnace slag. Blast furnace slag is transformed into a high-quality product through grinding

Cement Mill, Clinker Mill SBCCO-CEMENT

Vertical Roller Mill. Vertical Roller Mill for Cement Raw Material; Cement Mill, Clinker Mill; Slag Mill; Coal Grinding Mill; Ball Mill; Rotary Kiln; 60px !important;}”]We provide various types of Cement Mill, Clinker Mills,

Comparison Of Cement Vertical Roller Mill And Roller

When grinding raw meal, the unit power consumption of the vertical roller mill and the roller press is about the same, which is 7-8kWh/t. But the vertical mill is usually slightly higher. The system of the vertical grinding mill is simple and stable. It has ideal adaptability to material moisture and can achieve the goal of energy saving on the

industrial grinding mill equipment milling machine

锤式破碎机海关编码

200tph crusher price list in india

تصنيع الأسطوانة الناقل للتعدين

المكتب الرئيسي

مصانع فريزر محدودة

أسعار آلات طحن الحبوب المحلية

آلة طحن تقسيم الرأس

tarkwa mines gold equipment

مطحنة الأنسجة zcrusher

Price of balram DXN making machine

الجزائر سحق الانتقامي

حبيبات الأسمدة الدولوميت المحبب الأسمدة الدولوميت المبدل

advance ore processing technology copper

بيع آلة مطحنة لموزمبيق

كرنك مطحنة خام الذهب

jual jaw crusher in semarang jaw tengah

آلة كسارة مخروطية مركبة

آلة تجهيز جوز الهند للبيع في سري لانكا

توليف لمواد البناء الإيكولوجي لبناء مدينة موفرة للطاقة وأهميتها

ماكينات كسارة المحجر للبيع في الجزائر

شنغهاي كسارة مخروط هيدروليكي HPC مع CE ISO

كيفية الحصول على ترخيص تكسير الحجارة

talcum primer crusher dijual

كسارة الحجر طاقة المصنع الحد الأدنى

عمال مطاحون يرشحون قائمة الاسكان

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20