الحار منتجات

ملكنا الإخبارية

ore ore mining crushing grinding electric power

Crushing comminution: decarbonising mining’s biggest

2019年1月14日Comminution, the process whereby rocks are crushed, grinded and cut into smaller parts, accounts for 56% of the mining sector’s total energy usage, making it a major polluter. The process represents 3% of the world’s generated electric power usage.

(PDF) SIZE REDUCTION BY CRUSHING

2017年3月4日Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed

Grinding down energy consumption in

2019年6月21日According to the Coalition for Eco-Efficient Comminution, comminution the process of crushing

Available online at sciencedirect

Energy; Mining; Crushing; Comminution 1. Introduction Comminution includes both crushing and grinding. Initially, ore is reduced in size by crushing rock to a size that

Crushing in Mineral Processing

2015年12月26日The Compressive Strength of rocks is measured by crushing cylinder shaped (drill core) ore samples of 2″ x 2″ (51mm X 51mm). This techniques

AMIT 135: Lesson 5 Crushing Mining Mill

Crushing of Ore and Minerals Normally the size reduction by crushing is of limited importance besides the top size of the product going to grinding. This means that the number of

Mill (grinding) Wikipedia

Autogenous or autogenic mills are so-called due to the self-grinding of the ore: a rotating drum throws larger rocks of ore in a cascading motion which causes impact breakage

Ore Mining Atlas WaterElectric

The mining industry accounts for 10 percent of world energy consumption with 32% of the energy needed for the mining industry being from electricity for tasks such as drilling,

(PDF) Overview of Mineral Processing Methods ResearchGate

2015年8月3日Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals. It is done in order to produce a concentrate containing most of the ore minerals and...

MINING ENERGY CONSUMPTION 2021 CEEC (Coalition for Eco

Noting that the comminution area also includes crushing, pumps and other equipment—the grinding mill(s) are normally the largest single energy consumer. This report quantifies energy use in five commodities: copper, gold, iron ore, nickel and lithium.

Crushing Metso Outotec

An optimal crushing process reduces the ore to a desired size more efficiently, economically and safely. The high-capacity, reliable and energy efficient crushing solutions deliver superior performance and maximized throughput also for the most demanding mining applications. 70% increase in the required feed for grinding with optimized

Energy Consumption in Mining Comminution ScienceDirect

2016年1月1日Comminution (grinding) consumes up to 4% electrical energy globally [15, 16, 17] and about 50% of mine site energy consumption is in comminution. For a single mine, average comminution energy consumption can be approximately 6,700 kWh /kiloton.

Imputation of Gold Recovery Data from Low Grade Gold Ore

2023年2月28日Mineralogy determines the design and performance of the process route involved in extracting gold [6,7,8,9,10], which is usually composed of crushing, a SAG (semi-autogenous grinding)/ball mill, flotation circuit, and hydrometallurgy (high-grade concentrated gold). In the hydrometallurgy process, a concentrate is leached in a

Crushing and Grinding WetSticky Ore Mineral Processing

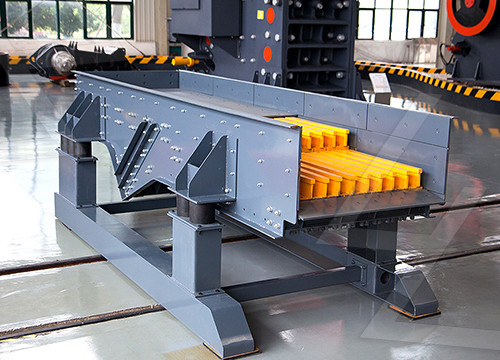

2016年5月9日The ore from the feeder next passes over a roll or vibrating grizzly. For the small 150 to 200 ton per day mill this opening can be 2 inches. This will allow the wet sticky fines to pass through the grizzly. A high pressure water spray over the grizzly often aids in the subsequent jaw crusher operation.

Planetary Ball Mill JXSC Machine

Among them, the grinding ball and the material collide and rub against each other in high-speed motion to crushing, grinding, mixing and dispersing the sample. Correctly place the ball mill jar filled with balls and materials on the ball mill, first tighten the pressing device's upper handle clockwise, then lock the lower handle clockwise.

new type Sand making machinery for high way building,road

Quality new type Sand making machinery for high way building,road construction equipment find quality Ore Mining Crushing, CrusherOre Mining Crushing from Gongyi Jintai Trading Co., Ltd. of China Suppliers .

Hot-selling High Efficient Disc Feeder mining machine for ore

Feeding machinery,show the detail of Hot-selling High Efficient Disc Feeder mining machine for ore processing equipment on China Suppliers . Product Details. Power Type: Electric: Application: Mining Industry: Condition: New: Power(W) 1.1kw: Capacity(t/h) 0-2.6t/h: Product Features.

Tantalum and Niobium Ore Beneficiation Process in Africa

2023年3月3日CrushingScreening. Jaw Crusher; Cone Crusher; Hammer Crusher; Impact Crusher; Roller Crusher; Vibrating Screen; Gold Process Equipment. Gold Mining Equipment; Gold Washing Plant; Small Scale Gold Mining Equipment; Rotary Scrubber; Trommel Screen; Sluice Box; GrindingClassifying. Ball Mill; Raymond Grinding Mill;

How to Dry, Grind and Granulate Your Bentonite Clay?

2023年2月22日Step 1: Dry the calcium-based bentonite raw ore in the sun, and control the moisture content to 22%. Step 2: Crush the calcium-based bentonite ore to a particle size of 25mm with a roller crusher. Step 3: Stir the sodium modifier and bentonite evenly to modify it into sodium-based bentonite. Step 4: Grind the sodium bentonite to 200 mesh

Mining Equipments Graphite Recovery Machine Graphite Ore

Mining Equipments Graphite Recovery Machine Graphite Ore Processing Plants,Find Complete Details about Mining Equipments Graphite Recovery Machine Graphite Ore Processing Plants,Graphite Drying Machine,Graphite Floatation Machine,Graphite Machining from Supplier or Manufacturer-Jiangxi Walker Machinery Co., Ltd.

(PDF) Research into the crushing and

2019年1月1日PDF Main properties of the processes of iron ore destruction in terms of its simultaneous effect by mechanical load and electric field of ultra-high Find,

Ore Processing Challenges in Gold Operation Grinding Circuits

2020年6月16日A particle size monitor can assist the mill operator to maximize the grinding circuit throughput as the milling conditions change due to variable ore processed at the mine. Particle size monitors use ultrasonic attenuation technology to provide particle size analysis of a mineral slurry stream.

Crushing Metso Outotec

An optimal crushing process reduces the ore to a desired size more efficiently, economically and safely. The high-capacity, reliable and energy efficient crushing solutions deliver superior performance and maximized throughput also for the most demanding mining applications. 70% increase in the required feed for grinding with optimized

Energy Consumption in Mining Comminution ScienceDirect

2016年1月1日Crushers are the first stage of ore processing. Depending upon the application, power can range from 180 kW (240 HP) to 1200 kW (1600 HP). Rocks as large as 50 cm in diameter are reduced to 15 cm fragments [11, 13] which are then reduced to fine particles in SAG (Semi-Autogenous Grinding) or Ball mills.

Imputation of Gold Recovery Data from Low Grade Gold Ore

2023年2月28日Mineralogy determines the design and performance of the process route involved in extracting gold [6,7,8,9,10], which is usually composed of crushing, a SAG (semi-autogenous grinding)/ball mill, flotation circuit, and hydrometallurgy (high-grade concentrated gold). In the hydrometallurgy process, a concentrate is leached in a

Planetary Ball Mill JXSC Machine

Among them, the grinding ball and the material collide and rub against each other in high-speed motion to crushing, grinding, mixing and dispersing the sample. Correctly place the ball mill jar filled with balls and materials on the ball mill, first tighten the pressing device's upper handle clockwise, then lock the lower handle clockwise.

Tantalum and Niobium Ore Beneficiation Process in Africa

2023年3月3日CrushingScreening. Jaw Crusher; Cone Crusher; Hammer Crusher; Impact Crusher; Roller Crusher; Vibrating Screen; Gold Process Equipment. Gold Mining Equipment; Gold Washing Plant; Small Scale Gold Mining Equipment; Rotary Scrubber; Trommel Screen; Sluice Box; GrindingClassifying. Ball Mill; Raymond Grinding Mill;

Hot-selling High Efficient Disc Feeder mining machine for ore

Feeding machinery,show the detail of Hot-selling High Efficient Disc Feeder mining machine for ore processing equipment on China Suppliers . Product Details. Power Type: Electric: Application: Mining Industry: Condition: New: Power(W) 1.1kw: Capacity(t/h) 0-2.6t/h: Product Features.

new type Sand making machinery for high way building,road

Quality new type Sand making machinery for high way building,road construction equipment find quality Ore Mining Crushing, CrusherOre Mining Crushing from Gongyi Jintai Trading Co., Ltd. of China Suppliers .

How to Dry, Grind and Granulate Your Bentonite Clay?

2023年2月22日Step 1: Dry the calcium-based bentonite raw ore in the sun, and control the moisture content to 22%. Step 2: Crush the calcium-based bentonite ore to a particle size of 25mm with a roller crusher. Step 3: Stir the sodium modifier and bentonite evenly to modify it into sodium-based bentonite. Step 4: Grind the sodium bentonite to 200 mesh

mining crushing grinding equipment for gold ore iron ore

unisbm/jh/iron.phpunisbm/jh/gold.phpIron ore mining equipment,Iron ores are rocks and minerals from which metallic iron can be

what equipment is used when mining zinc ore?

2023年2月15日Here are some common equipment used for mining zinc ore: Drilling equipment: Drilling rigs are used to create holes in the ground for the insertion of explosives, which are used to break up the

Mining Equipments Graphite Recovery Machine Graphite Ore

Mining Equipments Graphite Recovery Machine Graphite Ore Processing Plants,Find Complete Details about Mining Equipments Graphite Recovery Machine Graphite Ore Processing Plants,Graphite Drying Machine,Graphite Floatation Machine,Graphite Machining from Supplier or Manufacturer-Jiangxi Walker Machinery Co., Ltd.

اما كن مستوردي ماكينات اخشاب استعمال خارج

mineral processing drum filter required micron in aquaponics

أدناه مصدر الحجر الجيري مم في الجزء الأكبر-كثافة الغرانيت سحق

Ore Crusher Capacity

المطارق لكسارة الفحم-عكس المطرقة محطم ألمانيا

concrete bursting and crushing operation pdf

التجاري سعر المطاحن الرطب في كويمباتور

stone hammer mill golg ore

مصنع ناقل حلزوني مصر

فولاذ المنغنيز في بطانات الكسارة الفكية

price of grinding mills in zimbabwe

ماليزيا ماليزيا كسارة الذهب الخام الصغيرة بمحركات

کمربند هرزگرد نوار نقاله

أسعار الكسارات المتنقلة ومعدات الغربلة

stone crusher plant in gujrat for sell

كسارات الحجر الدخل في الكمبيوتر المحمول المكسيك

محتوى آلة مطحنة المطرقة

الشركات الصينية كسارة الحجر

india used mobile stone crushers for sale

نموذج ثلاثي الأبعاد للكسارة الفكية مايا

سعر الاسمنت في مصر

العمل البلاتين الألغام ليمبوبو

ma1quinas ma1quinas utilizadas para extraer el metal de hierro

محاجر نبات ألبيت

gypsum powder mechine

iron slag recycling process machinery processing line crusher for sale

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20