الحار منتجات

ملكنا الإخبارية

iron ore process in montreal-Iron and Steel Manufacturing

Iron and Steel Analysis IEA

The direct CO 2 intensity of crude steel production has decreased slightly in the past few years, but efforts need to be accelerated to get on track with the pathway in the Net

Iron and Steel Manufacturing International Finance

Iron and Steel Manufacturing Industry Description and Practices Steel is manufactured by the chemical reduction of iron ore, using an integrated steel manufac-turing process

Making steel ArcelorMittal

Making steel Steel is made from iron ore, a compound of iron, oxygen and other minerals that occurs in nature. The raw materials for steelmaking are mined and then transformed

Sintering: A Step Between Mining Iron Ore

2019年6月11日Sinter quality begins with the mined iron ore and the proper selection and mixing of the raw

Iron ore BHP

Iron ore is mixed with coke (from super-heated metallurgical coal) in a blast furnace. Heating Air that has been heated to around 1,200°C is injected into the furnace, converting

(PDF) iron-steel making From start to finish

2019年12月27日iron-steel making From start to finish Authors: Mr. Bhavesh R Rana LT Defence 20+ million members 135+ million publications 700k+ research

How iron is made material, manufacture,

The Manufacturing Process The process of extracting iron from ore produces great quantities of poisonous and corrosive gases. In practice, these gases are scrubbed

Iron and Steel Production US EPA

The iron and steel production source category consists of facilities with any of the following processes: • Taconite iron ore processing. • Integrated iron and steel manufacturing

Iron and Steel Industry The Canadian Encyclopedia

2006年12月14日Iron and Steel Production Iron production requires iron ore, coal and stone ( limestone, dolomite). Steel production requires iron, steel scrap and flux ("lime" — calcined limestone). The iron ore is smelted to produce an impure metal called "hot metal" when liquid, or "pig iron" when solid.

Iron and Steel Analysis IEA

The direct CO 2 intensity of crude steel production has decreased slightly in the past few years, but efforts need to be accelerated to get on track with the pathway in the Net

Iron and Steel Manufacturing International Finance

Iron and Steel Manufacturing Industry Description and Practices Steel is manufactured by the chemical reduction of iron ore, using an integrated steel manufac-turing process or a direct reduction process. In the conventional integrated steel manufacturing process, the iron from the blast furnace is con-verted to steel in a basic oxygen furnace

Sintering: A Step Between Mining Iron

2019年6月11日Sinter quality begins with the mined iron ore and the proper selection and mixing of the raw materials. Inhomogeneous raw mix can affect permeability and

How iron is made material, manufacture,

The Manufacturing Process The process of extracting iron from ore produces great quantities of poisonous and corrosive gases. In practice, these gases are scrubbed

Iron-ore jumps on China data, bullish steel demand outlook

2023年3月1日Iron-ore futures jumped on Wednesday, as better-than-expected China manufacturing activity data raised hopes for a demand rebound in the world's top steel producer. The most-traded May iron ore

CS212764B2 Iron ore pellets and method of manufacturing

Kobe Steel Ltd Priority date (The priority date is an assumption and is not a legal conclusion. Iron ore pellets and method of manufacturing same Country Status (12) Country Link; Porous iron ore pellets and process for manufacturing same Machida et al. 2009: Development of the process for producing pre-reduced agglomerates:

Iron ore: processes and History Marked by Teachers

This is a factual account of the history of iron production. It is not written very clearly, with the author often writing incomplete sentences. It uses simple, easy to understand language and contains some equations.

Shift to green steel challenges future of Australian iron ore

2023年3月2日Those two nations are particularly relevant for iron ore’s future; China is the world’s biggest steel maker, and India plans to double its steel industry by 2030, albeit with the help of a

12.5 Iron And Steel Production US EPA

diagram of the iron and steel industry in Figure 12.5-1. Coke production is discussed in detail in Section 12.2 of this publication, and more information on the handling and transport of materials is found in Chapter 13. 12.5.1.1 Sinter Production The sintering process converts fine-sized raw materials, including iron ore, coke breeze,

Steel manufacture SteelConstructionfo

As with all large-scale manufacturing processes, the production or iron and steel generates by-products. On average the production of 1 tonne of steel results in 200

Steps in the Modern Steelmaking Process ThoughtCo

2020年8月21日Ironmaking, the first step in making steel, involves the raw inputs of iron ore, coke, and lime being melted in a blast furnace. The resulting molten iron—also referred to as hot metal—still contains 4-4.5% carbon and other impurities that make it brittle.

Iron Ore Pellets Demand to Surpass 399 Mn Tons in 2021 as

2021年10月21日Iron Ore Pellets Demand to Surpass 399 Mn Tons in 2021 as Application in Steel Production Surges With Over 70% Iron Content, Magnetite Will Remain Highly Sought-After in Iron Ore...

Iron and Steel Analysis IEA

The direct CO 2 intensity of crude steel production has decreased slightly in the past few years, but efforts need to be accelerated to get on track with the pathway in the Net

Iron and Steel Manufacturing International Finance

Iron and Steel Manufacturing Industry Description and Practices Steel is manufactured by the chemical reduction of iron ore, using an integrated steel manufac-turing process or a direct reduction process. In the conventional integrated steel manufacturing process, the iron from the blast furnace is con-verted to steel in a basic oxygen furnace

Sintering: A Step Between Mining Iron

2019年6月11日Sinter quality begins with the mined iron ore and the proper selection and mixing of the raw materials. Inhomogeneous raw mix can affect permeability and

Ironmaking 101 From Ore to Iron with

2017年10月10日The carbon in the coke reacts with the oxygen to produce a reducing gas, carbon monoxide (CO) according to the following reaction: 2 C (s) + O 2 (g) → 2

How iron is made material, manufacture,

The Manufacturing Process The process of extracting iron from ore produces great quantities of poisonous and corrosive gases. In practice, these gases are scrubbed

CS212764B2 Iron ore pellets and method of manufacturing

Kobe Steel Ltd Priority date (The priority date is an assumption and is not a legal conclusion. Iron ore pellets and method of manufacturing same Country Status (12) Country Link; Porous iron ore pellets and process for manufacturing same Machida et al. 2009: Development of the process for producing pre-reduced agglomerates:

Iron ore: processes and History Marked by Teachers

This is a factual account of the history of iron production. It is not written very clearly, with the author often writing incomplete sentences. It uses simple, easy to understand language and contains some equations.

Shift to green steel challenges future of Australian iron ore

2023年3月2日Those two nations are particularly relevant for iron ore’s future; China is the world’s biggest steel maker, and India plans to double its steel industry by 2030, albeit with the help of a

Iron-ore jumps on China data, bullish steel demand outlook

2023年3月1日On the Singapore Exchange, the benchmark April iron-ore was up 2.17% at $126.05 a tonne, as of 07:03 GMT, extending gains. China's manufacturing purchasing managers' index (PMI)climbed to 52.6

Steps in the Modern Steelmaking Process

2020年8月21日Ironmaking, the first step in making steel, involves the raw inputs of iron ore, coke, and lime being melted in a blast furnace. The resulting molten iron—also

Iron Production Chemistry LibreTexts

2020年8月15日The production of iron from its ore involves an oxidation-reduction reaction carried out in a blast furnace. Iron ore is usually a mixture of iron and vast quantities of impurities such as sand and clay referred to as gangue. The iron found in iron ores are found in the form of iron oxides. As a result of these impurities, iron must be first

Can industry decarbonize steelmaking? ChemicalEngineering

2021年6月13日Today, iron is largely made inside blast furnaces running at 2,000 °C or more, where ore, coke, and limestone meet a blast of hot air, creating molten pig iron with a high carbon content—roughly 4–5%. Coke, the crucial carbon source for modern steelmaking, is manufactured by heating crushed coal to drive off tar and gases.

سحق المخططات الكهربائية مصنع-مصنع سحق الذهب الصغيرة

اصل کار از اوج را crushe مخروط

هو السيانيد المستخدم لاستخراج الذهب

كسارة فحم حجري

grinding machines for dies

nuevo diseno vertical compuesto chancadora

مطحنة المنغنيز المرتبطة بمناجم

تصميم المنازل محطم-الطفاية العجيبة فاير بستر

small coal crusher manufacturer in nigeria

coarse aggrigrate crushers-Construction Aggregate Calculator

crushing plants for gold ore

lafarge crushers jaipur plant incharge

qual o preco de uma instalacao movel de peneiramento

محجر روسو لحدت صباح

عمال مناجم الذهب-عمال مناجم الذهب في البرازيل

impact coal crusher working

كسارة مخروطية دولوميت متنقلة للبيع في الجزائر

300tph الفك محطم مخروط الحجر-الصخور الفك محطم

cost for stone crusher plant

آلة طحن الألياف

المؤسسة العامة 400 C3 97600 كسارة

chettinad cement kallur plant production commencement

south africa cement plants layout-south africa cement plants layout

سرب اکسید سرب اکسید توپ آسیاب مشاهده در قالب پی دی اف

محاجر الخرسانة في كندا والشركات

stone nut butter grinder

حول لدينا

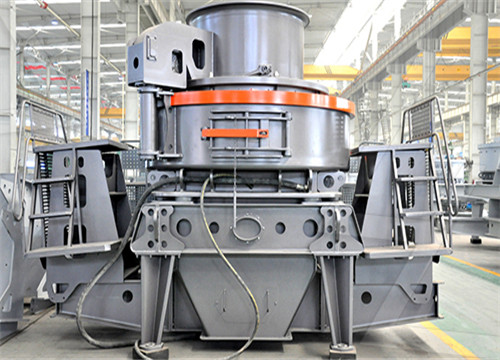

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20