الحار منتجات

ملكنا الإخبارية

crushing high temperature slag blocks

High-temperature modification and air-quenching

2021年8月5日The precipitated phase of the original slag at high temperature is periclase and the precipitated temperature is above 1650 °C. The original steel slag is already

Centrifugal granulation characteristics of molten blast

2018年9月1日The experimental system for the centrifugal granulation of molten slag, as shown in Fig. 1 (a), mainly consisted of a molten slag supplying unit, a centrifugal

Effect of the Curing Condition and High-Temperature

2021年2月23日In this study, the effect of curing temperature on the properties of slag cement concrete after high-temperature exposure was studied, and elevated curing

A heat transfer model for high titania T slag blocks SciELO

A heat transfer model for high titania slag blocks by H. Kotzé*, and P.C. Pistorius† Synopsis Titania slag is used as feedstock in the production of titanium dioxide pigment.

A heat transfer model for high titania slag blocks SAIMM

slag block. Calibration of the model was conducted by fitting the internal slag block temperatures as predicted by the model, to actual internal temperature measurements

(PDF) Research on Measurement Method of High

2020年6月2日s a designed and built verification experimental system for slag flow measurement program. The system is mainly composed of an aluminum structure frame

crushing high temperature slag blocks tablesandthyme.co.za

Dec 24, 2018 High zirconia blocks have very high viscosity even in high temperature, so its refractoriness is high, usually higher than 1825℃. The cold crushing strength of high

Crushing High Temperature Slag Blocks travelconsortium.africa

2020年5月19日From shimmering blues and greens to darker grays and black. The colors of the slag are based on its chemical composition, including the mixture of metal oxides

Production of artificial aggregates from steel-making slag:

2019年11月20日Extensive studies have used granulation or compact fabrication methods to turn steel slag powder into the pellet or block, which is then hardened with

Three-Stage Method Energy–Mass Coupling High SpringerLink

2021年6月14日High-temperature molten steel slag is a large amount of industrial solid waste containing available heat energy and resources. This stone introduces an efficient and comprehensive utilization process of high-temperature molten steel slag. The waste heat energy in the high-temperature molten steel slag can be fully recovered through

Recycling and applications of steel slag aggregates

2022年1月1日A preliminary treatment refers to the quenching, splitting, and crushing of molten steel slag during the process of steelmaking or adding silica fume and fly ash, which include SiO 2 and Al 2 O 3 phases, into molten steel slag to reduce the content of free CaO.

Minerals Free Full-Text Effect of High Temperature

2022年12月30日This study investigates the pattern of influence of blast furnace slag tempering on the composition and structure of steel slag. The chemical composition, equilibrium phase composition, microscopic morphological characteristics and elemental composition of microscopic regions of steel slag and blast furnace slag modified by high

A heat transfer model for high titania T slag blocks SciELO

A heat transfer model for high titania slag blocks by H. Kotzé*, and P.C. Pistorius† Synopsis Titania slag is used as feedstock in the production of titanium dioxide pigment. It (titania slag) is the product of ilmenite smelting, a process whereby ilmenite is reduced at high temperature utilizing anthracite as a reducing agent.

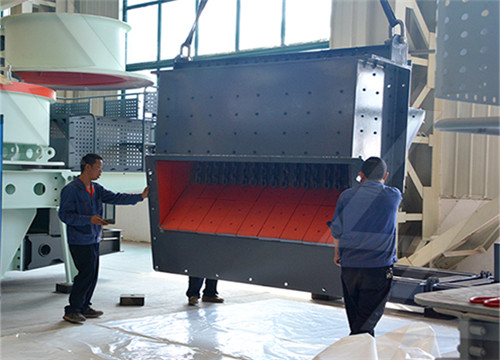

JPHA Apparatus for crushing high temperature slag

The conveying lines 6, 7 for the crushed high temp. slag are independently arranged under the large bulk crusher 4 and the small bulk crusher 5. By this method, the large bulk high temp. slag and the small bulk high temp. slag are efficiently separated at the same place before crushing and each slag is independently crushed and granulated.

crushing high temperature slag blocks tablesandthyme.co.za

Dec 24, 2018 High zirconia blocks have very high viscosity even in high temperature, so its refractoriness is high, usually higher than 1825℃. The cold crushing strength of high zirconia bricks is between 100~430Mpa, modulus of rupture can reach to 17.8~76.3Mpa, refractoriness under load(RUL) is higher than 1650℃. Read More

crushing high temperature slag blocks

B. INTERMEDIATE TEMPERATURE THERMAL INSULATION 1. 16°C through 100°C i.e. Hot water and steam condensate. 2. 101°C through 315°C i.e. Steam, high temperature hot water. C. HIGH TEMPERATURE THERMAL INSULATION 1. 316°C through 815°C i.e. Turbines, breechings, stacks, exhausts, incinerators, boilers. 2.2 GENERIC TYPES AND

Blast furnace slag sensible heat recovery method and system

The invention discloses a blast furnace slag sensible heat recovery method and system. Blast furnace slag flows out of a slag ditch (1) and then enters a rolling machine (2), and at the same time, cold blast furnace slag is conveyed to the rolling machine (2); the cold blast furnace slag and the blast furnace slag fall onto a uniform heating bed (3) after being

sbm/sbm method of crushing silicon blocks.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Aggregates for Concrete

Chapter 5—Blast-furnace slag aggregates, p. E1-21 5.1—Blast-furnace slag 5.1.1—Definition 5.1.2—Properties 5.1.3—Availability Chapter 6—Lightweight aggregates, p. E1-21 produced by crushing natural stone. Crushing, screening, and washing may be used to process aggregates from either sand and gravel deposits or stone quarries

Ferrochrome Slag Feasibility as a Raw Material in Refractories

2020年5月21日The liquid phase formation above 1200 °C limits the FeCr slag use as aggregate in refractory castables, thus the maximum service temperature for these novel slag-based refractory materials is 1200 °C. Cold crushing strength value of FeCr slag-containing specimens was as high as 91 MPa.

Converting ladle slag into high-strength cementing material by

2021年11月1日Ground granulated blast furnace slag (GGBFS) Cement replacement [10], high-performance concrete [11], electromagnetic performance [12], and steel reinforcement material [13] Ladle slag

Three-Stage Method Energy–Mass Coupling High SpringerLink

2021年6月14日The high-temperature solid steel slag is cooled by the waterwall down to medium temperature. In the third stage, CO 2 is the heat recovery medium. Through counterflow heat exchange, the normal-temperature CO 2 and the medium-temperature solid steel slag change into normal-temperature solid steel slag and high-temperature

Recycling and applications of steel slag aggregates

2022年1月1日A preliminary treatment refers to the quenching, splitting, and crushing of molten steel slag during the process of steelmaking or adding silica fume and fly ash, which include SiO 2 and Al 2 O 3 phases, into molten steel slag to reduce the content of free CaO.

Minerals Free Full-Text Effect of High Temperature

2022年12月30日This study investigates the pattern of influence of blast furnace slag tempering on the composition and structure of steel slag. The chemical composition, equilibrium phase composition, microscopic morphological characteristics and elemental composition of microscopic regions of steel slag and blast furnace slag modified by high

A heat transfer model for high titania T slag blocks SciELO

A heat transfer model for high titania slag blocks by H. Kotzé*, and P.C. Pistorius† Synopsis Titania slag is used as feedstock in the production of titanium dioxide pigment. It (titania slag) is the product of ilmenite smelting, a process whereby ilmenite is reduced at high temperature utilizing anthracite as a reducing agent.

crushing high temperature slag blocks tablesandthyme.co.za

Dec 24, 2018 High zirconia blocks have very high viscosity even in high temperature, so its refractoriness is high, usually higher than 1825℃. The cold crushing strength of high zirconia bricks is between 100~430Mpa, modulus of rupture can reach to 17.8~76.3Mpa, refractoriness under load(RUL) is higher than 1650℃. Read More

crushing high temperature slag blocks

B. INTERMEDIATE TEMPERATURE THERMAL INSULATION 1. 16°C through 100°C i.e. Hot water and steam condensate. 2. 101°C through 315°C i.e. Steam, high temperature hot water. C. HIGH TEMPERATURE THERMAL INSULATION 1. 316°C through 815°C i.e. Turbines, breechings, stacks, exhausts, incinerators, boilers. 2.2 GENERIC TYPES AND

JPHA Apparatus for crushing high temperature slag

The conveying lines 6, 7 for the crushed high temp. slag are independently arranged under the large bulk crusher 4 and the small bulk crusher 5. By this method, the large bulk high temp. slag and the small bulk high temp. slag are efficiently separated at the same place before crushing and each slag is independently crushed and granulated.

Blast furnace slag sensible heat recovery method and system

The invention discloses a blast furnace slag sensible heat recovery method and system. Blast furnace slag flows out of a slag ditch (1) and then enters a rolling machine (2), and at the same time, cold blast furnace slag is conveyed to the rolling machine (2); the cold blast furnace slag and the blast furnace slag fall onto a uniform heating bed (3) after being

Aggregates for Concrete

Chapter 5—Blast-furnace slag aggregates, p. E1-21 5.1—Blast-furnace slag 5.1.1—Definition 5.1.2—Properties 5.1.3—Availability Chapter 6—Lightweight aggregates, p. E1-21 produced by crushing natural stone. Crushing, screening, and washing may be used to process aggregates from either sand and gravel deposits or stone quarries

Ferrochrome Slag Feasibility as a Raw Material in Refractories

2020年5月21日The liquid phase formation above 1200 °C limits the FeCr slag use as aggregate in refractory castables, thus the maximum service temperature for these novel slag-based refractory materials is 1200 °C. Cold crushing strength value of FeCr slag-containing specimens was as high as 91 MPa.

Converting ladle slag into high-strength cementing material by

2021年11月1日Zhong et al. [61] found that raise carbonation temperature from 30 C to 70 C, the porosity of steel slag block decreased from 39.6% to 26.6%. Zhang et al. [33] demonstrated that although the...

Standards and Testing for Refractory Materials.

The general requirements for refractories are (i) the ability to withstand high temperatures and trap heat within a small area, such as a furnace; (ii) the ability to withstand sudden temperature changes; (iii) the ability to withstand load at service conditions; and (iv) the able to handle chemical and abrasive action of materials such as liquid metal, liquid slag,

سعر المحمولة كسارة الفك

منتجات المحاجر ces سكريد الأرضيات الخرسانية

سحق البذور الية

معدات التكسير من ألمانيا

مطحنة ميكرون في جدة

used stone crusher on sale in kenya

miningcenter less grinding machine

آلة تكسير الحجر الألمانية

maquinaria para procesar caliza

آلة طحن عرض فيديو

high speed rotation impact crusher counter attack crusher

أسعار كسارة الحجر في كسارة الرمل اوزبكستان م في

الأتمتة في ناقل الفحم باستخدام plc

مطحنة سحق للفوسفات الصخري

أوراق على الفحم كسارة الفلبين

سعر الإيجار كسارة تأثير المحمول

سنگ کوچک برای فروش سنگ شکن

gold african mining stocks

كسارة مخروطية للبيع في نيوزيلندا

mobile crusher china limestone

除雾器叶片研究的重要性

second hand morgardshammar jaw crusher

ميتس محطة كسارة tph

محامل محامل كسارة الفك

stone crusher price list mexico

طريقة عمل طاحونة فى مصر

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20