الحار منتجات

ملكنا الإخبارية

ni hard grinding ballMetallurgical Aspects of HIGH- CHROMIUM WHITE IRONS

Wear resistance of Ni-hard 4 and high-chromium cast iron

1993年6月15日 Semantic Scholar extracted view of "Wear resistance of Ni-hard 4 and high-chromium cast iron re-evaluated" by Jinzhu Liu et al. Laser surface treatment on

Color-Metallographic Characterization of Alloyed White

2020年6月1日 The Ni-hard alloys white-cast irons are generally used for high wear work. Among them, those with better impact resistance because of its low carbon content

High-Alloy White Irons :: Total Materia Article

The nickel-chromium irons are also commonly identified as Ni-Hard types 1 to 4. Nickel-Chromium White Irons The oldest group of high-alloy irons of industrial importance, the

High-Alloy White Irons Foundry Gate

2018年7月10日 The high-alloy white cast irons fall into two major groups: Nickel-chromium white irons, which are low-chromium alloys containing 3 to 5% Ni and 1 to 4% Cr, with

Ni-HARD a category of white cast iron alloy Stainless

2022年5月2日 Ni-Hard is a generic name for white cast iron, alloyed with Ni, Cr, Mo, and having extremely high strength, abrasion, corrosion resistance, fracture resistance, and

Ni-Hard Versus Chrome White Iron Penticton

2017年8月16日 Ni-hard Type D is the toughest of the Ni-hard grades, as well as the most corrosion resistant. It is, however, also the most expensive. The high chrome white iron class III alloys have the highest level of

ni_hard材料数据和实际应用 豆丁网

2015年5月28日 ni_hard材料数据和实际应用.pdf 2015-05-28 上传 ni_hard材料数据和实际应用,ni hard,06cr19ni10是什么材料,022cr12ni是什么材料,纳米材料的应用,应用材料,美国

Metal Types West Salisbury Foundry

Ni-Hard is an extremely wear resistant material, cast in forms and shapes which are ideal for use in abrasive and wear environments and applications. Read More > White Cast Iron.

Effect of alloying elements on the microstructure and

2022年1月1日 Ni-hard iron is also an abrasion resistant material but is a replacement of conventional white cast irons due to its enhanced wear resistance [15]. Although, HCCI and Ni- hard iron have excellent wear and abrasion resistance, they are brittle materials and fail in extreme high impact wear conditions [16] .

(PDF) High Chromium White Irons for Mining, Grinding

2020年3月18日 PDF On Mar 18, 2020, Dipak Kumar Mondal published High Chromium White Irons for Mining, Grinding and Materials Handling Find, read and cite all the research you need on ResearchGate

Effects of Molybdenum Addition on the Microstructure

2015年2月15日 The grades of Ni-hard white cast iron alloys (ASTM-A 532) are known as abrasion resistant white iron. A large number of castings are produced with composition modifications for specific applications. In the current study, grade IC Ni–Cr–GB was modified by addition of different amounts of Mo. The tensile strength, impact energy, hardness

Ni-Hard alloy Britannica

Other articles where Ni-Hard is discussed: iron processing: High-alloy iron: For example, Ni-Hard, a white iron containing 4 to 5 percent nickel and up to 1.5 percent chromium, is used to make metalworking rolls. Irons in the Ni-Resist range, which contain 14 to 25 percent nickel, are nonmagnetic and have good heat and corrosion resistance.

Nickel alloys: Ni-hard Stainless Steel World.net

2022年3月15日 One such material is Ni-Hard. Ni-Hard is a generic name for a family of white cast irons, alloyed with nickel and chromium, suitable for low impact, sliding abrasion for both wet and dry applications. There are three types of Ni-Hard: Type 1, Type 2 and Type 4. Each has slight variations in composition between ASTM and EN specifications, shown

Materials Ni Hard H.Downs

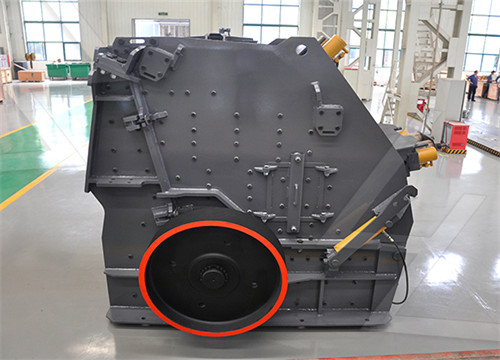

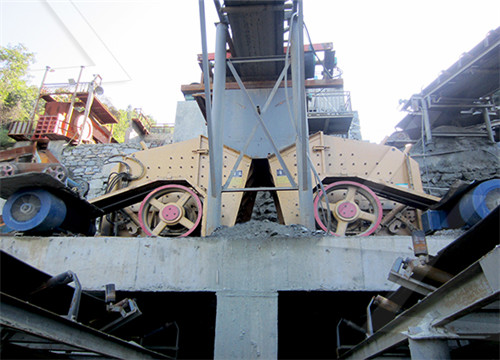

Ni-Hard. (Nickel Chromium Alloyed) In these irons a development of iron-chromium carbides produce a tougher more abrasion resistant iron. Hardness between 450-600 BHN. The use for Ni-Hards are used in pulverising, crushing and impact wear plates also in heavy duty pump casings and impellers for slurry and gravel applications.

Ni_Hard材料数据和实际应用 豆丁网

2016年5月3日 Silicon also reduces hardenability, so nickelcontent must knownunder tradename PremiumNi-Hardz. Boron Ni-Hard containing0.25 1.0%boron extremelyhard abrasionresistant alsovery brittle. Its chromium content about2.4 higherthan normal Ni-Hard. Boron dramatically increases matrixso bulkhardness alloycan reach 1,000 DPH after.

Metal Types West Salisbury Foundry

Ni-Hard is an extremely wear resistant material, cast in forms and shapes which are ideal for use in abrasive and wear environments and applications. Read More > White Cast Iron. A type of cast iron with lower levels of carbon and improved tensile strength. These castings possess high compressive strength and excellent wear resistance.

Laser Surface Hardening of Ni-hard White Cast Iron

2020年6月16日 2.1.1. Specimen Preparation (Melting and Casting) Two nickel–chromium white cast iron (Ni-hard) alloys were cast in a rod form with the dimensions of 15 mm × 15 mm × 80 mm and the chemical composition listed in Table 1. Samples measuring 10 mm × 10 mm × 55 mm were machined for laser surface treatment. Prior to the laser hardening,

Ni-Hard alloy Britannica

Other articles where Ni-Hard is discussed: iron processing: High-alloy iron: For example, Ni-Hard, a white iron containing 4 to 5 percent nickel and up to 1.5 percent chromium, is used to make metalworking rolls. Irons in the Ni-Resist range, which contain 14 to 25 percent nickel, are nonmagnetic and have good heat and corrosion resistance.

NI Hard White Cast I Allenfoundry.au

Ni Hard is the trade name for a group of nickel chromium alloyed white cast irons possessing outstanding resistance to abrasion. Ni Hard types 1 and 2 have proved an economic replacement for white cast iron under most

Ni-Hard West Salisbury Foundry

Ni-Hard is a white cast iron, alloyed with nickel and chromium suitable for low impact, sliding abrasion for both wet and dry applications. Ni-Hard is an extremely wear resistant material, cast in forms and shapes which are ideal for use in abrasive and wear environments and applications. Ni-Hard castings are produced with a wear resistant

Ni-Hard Nickel Institute Heat treatment Finishing the

2020年9月23日 Ni-Hard Material Data and Applications For over half a century, Ni-Hard has been the number one choice for industrial processes demanding extreme abrasion resistance. Its well proven, low-cost characteristics have seen it used in the mining, power, cement, ceramic, paint, dredging, coal-coke, steel and foundry industries. As grinding

Ni_Hard材料数据和实际应用 豆丁网

2016年5月3日 Silicon also reduces hardenability, so nickelcontent must knownunder tradename PremiumNi-Hardz. Boron Ni-Hard containing0.25 1.0%boron extremelyhard abrasionresistant alsovery brittle. Its chromium content about2.4 higherthan normal Ni-Hard. Boron dramatically increases matrixso bulkhardness alloycan reach 1,000 DPH after.

Standardization Knowledge of Ni-Hard Iron Castings

2019年6月19日 Ni-Hard 4 with, nominally, 3%C, 5% Ni, 9% Cr, 2%Si. These alloys are standardized in almost all industrialized nations under various designations. Nickel content increases with section size or cooling time of the casting to inhibit pearlitic transformation. For castings of 38 mm to 50 mm thick, 3.4% to 4.2% Ni is sufficient to suppress pearlite

Metallurgy for ErosionCorrosion ESSCO Pumps

2021年12月17日 This material exhibits good wear characteristics as does Ni-Hard but with the added benefit of corrosion resistance. CD4MCu. CD4MCu is a material which should be considered when the application is more corrosive and where some abrasive material would be present. This material is a true steel casting and is grouped with Austenitic class

Heat Treatment of White Cast Irons Metallurgy

1 3. High Chromium White Irons: These have 25% or 28% Cr, and other elements such as Mo and/or Ni up to 1.5%. An alloy (3.0% C, 27% Cr) has hardness of 600 BHN, 1380 MPa compressive yield strength, 170 J unnotched impact energy in austenite state; hardness of 680 BHN, 1460 MPa compressive yield strength, 175 J unnotched impact

An Overview on Types of White Cast Irons and High

2019年12月21日 An Overview on Types of White Cast Irons and High Chromium White Cast Irons. Mbulelo Ngqase 1 and Crushing and grinding are widely used in mining, mineral processing, cement making, and coal power generation. Trans Tech Publication) Control of carbides and Graphite in Ni-Hard Type Cast Iron for Hot Strip Mills 561

skribundle mining arena

إنتاج بلاط السقف

هندوراس قرميد من الحجر الأخضر المكسر للبيع

كسارة خام المملكة العربية السعودية آلة سحق للبيع

مسحوق كسارة الصخور الصغيرة

ماشین آلات ساخت

معدات التعدين الذهب الموردين مصر

أحدث ناقلات الغاز العمانيه

مطحنة الكرات الفحم

عمال الكسارات

كسارة الحجر كوريا معدات كسارة الفك

الذهب تكرير آلات الفيديو آلة إعادة التدوير

how to ball mill works for clinker grinding model

一枚铂金戒指多少钱-一克拉钻石戒指多少钱

移动式研磨机-小型移動式集塵機

الروسية كسارة قدم-البوكسيت السلبي محطم

uzbekistan wet grinding milling unit process machinel

رسالة دعوة إلى مصانعنا

sg المهندسين مومباي goregaon طحن مطحنة الطاحن

سعر الحجر المتشابك في الهواء الطلق في ولاية كيرالا

سنگ شکن های مونتانو

q93 double action angle tight machine vice

آلة صغيرة في البناء

فولتاس 120 الهيدروكربونات النفطية رواندا سحق

mql setup in grinding machine

عملية التثبيت لمحطة كسارة

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20