الحار منتجات

ملكنا الإخبارية

high efficiency hematite iron ore beneficiation plant with iso certificate

Dry beneficiation of iron ore Mineral Processing

The haematite ore in South Africa is processed in a dry process to a HQ lump ore with 64 % iron content and a sintered fine ore with 63.5 % iron content. For fine ore beneficiation,

Hematite Ore Processing Plant/ Hematite

2022年8月31日 Hematite beneficiation production line has advantages of environmental protection, high efficiency and high hematite iron ore precision. Main equipment of hematite ore processing plant includes

Hematite beneficiation technology,processing of iron

2020年8月31日 Hematite beneficiation technology. 08-31-20; 1,887 Views; icon 1; Hematite beneficiation technology . With the rapid economic development, the iron ore

How to Extract Iron from Hematite: Methods and Plants

2023年2月15日 It is easy to extract iron from this kind of haematite by using gravity separation and magnetic separation. Medium-grained hematite refers to iron ore with an

SGS MINERALS SERVICES T3 SGS 960 11-2009

2022年3月25日 of the iron ore from the perspective of semi-autogenous milling. The CEET Crusher Index (Ci) is used to predict the SAG feed size distribution of the ore, and is

HEMATITE BENEFICIATION PROCESS, HEMATITE

2021年4月30日 The iron ore processed by a concentrator in Inner Mongolia is a mixture of high-grade iron ore and gangue, containing 40-50% iron. After ore washing, jigging, and

Wet beneficiation of low grade iron ores, or

Re-beneficiation of iron ore tailings from the conventional beneficiation plants The hematite ore (Fe 2 O 3) is always associated with limonitegoethite ores, which cannot be attracted by high gauss magnetic

hematite iron ore beneficiation plants Aquienergo

Iron Ore Beneficiation Plant Manufacturers . High efficiency hematite iron ore beneficiation plant iso certificate. High efficiency hematite iron ore beneficiation plant ISO certificate

Iron Ore Beneficiation Mineral Processing

The iron ore beneficiation process mainly includes crushing, screening, grinding (ball mill), classification (classifier), separation (gravity separation, flotation, magnetic separation),

Hematite Iron Ore Beneficiation Flow Chart Frjig

2020年7月27日 The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved

Design of beneficiation scheme of Banded Hematite

2021年1月1日 High aluminasilica content of Indian Iron ore resources require suitable beneficiation techniques to produce quality raw material for steel manufacturing. Banded Hematite Jasper (BHJ) reserves are abundantly available in India but not considered as an ore of Iron for production purposes due to its high Silica content and complex mineralogy.

China Iron Ore Beneficiation Plant, Iron Ore Beneficiation

China Iron Ore Beneficiation Plant manufacturers Select 2023 high quality Iron Ore Beneficiation Plant products in best price from certified Chinese Mining Equipment, Mining Machine suppliers, wholesalers and factory on Made-in-China High Efficiency : Large Handing Capacity; Workers Training Hematite Iron Ore Beneficiation Plant

A Beneficiation Study on a Low Grade Iron Ore by Gravity

2018年8月25日 In this , a sample from Tange-zagh iron mine was characterized by gravity and magnetic separation methods. The mineralogical studies showed that hematite and goethite are the main iron-bearing minerals with insignificant amounts of FeO. The results indicated that spiral separation yields higher separation efficiency than others.

Simec Mining 950tph Iron Ore Beneficiation Wash Plant

THE RESULTS. The two wet processing plants at Iron Knob and Iron Baron, with a combined throughput of 950 tonnes per hour, were designed, manufactured and delivered within 18 months from signing which was unprecedented for an Australian mining project of this nature. The two CDE installations have been performing with exceptional attrition

Development of a process flow sheet for beneficiation of

2007年1月1日 To identify and establish beneficiation techniques for banded hematite quartzite (BHQ) iron ore, a comprehensive research on BHQ ore treatment was carried out. The BHQ ore was assayed as 38.9wt

Mrs. Nirlipta P. Nayak,Dr. Abhimanyu Das And Dr. B. K.

2022年3月8日 grade occupies 28% and rest comes under unclassified categories. Iron ore in the size range of 8 mm to 0.15 mm are designated as fines, whereas, the ore below 0.15 mm are known as slime. Major resources of hematite iron ore are located in Orissa (3,789 million tons (33%)), Jharkhand (3,044 million tons (27%)),

10 Best Ore Beneficiation Plants for Sale (with Costs)

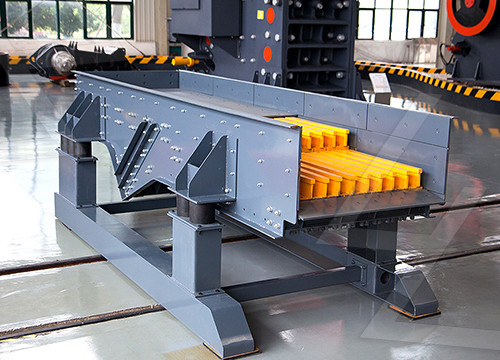

2021年3月24日 38%. Recovery rate. 74%. Manganese beneficiation machines: GZD-850×3000 vibrating feeder,PE-500×750 jaw crusher,Φ1200 cone crusher,B500x10 m belt conveyor, 2YK1535 inclined vibrating screen,Ф2700×4500 ball mill, High-strength magnetic separators. 07 150 TPH Bauxite ore beneficiation plant in Indonesia.

Beneficiation Strategies for Removal of Silica and Alumina

2021年11月24日 The processes selected to reduce impurity levels of these lower-grade iron ores will depend on the ore mineralogy and a thorough understanding of the separation process dynamics. The major concentration methods that may be applied to upgrade lower-grade lump iron ores include magnetic separation, wet and dry heavy media separation,

Dry beneficiation of iron ore Mineral Processing

The haematite ore in South Africa is processed in a dry process to a HQ lump ore with 64 % iron content and a sintered fine ore with 63.5 % iron content. For fine ore beneficiation, wet processes are used. Capacity at the Minas Rio is to be increased from 26.5 Mta capacity to 28 Mta in the forthcoming years.

Mrs. Nirlipta P. Nayak,Dr. Abhimanyu Das And Dr. B. K.

2022年3月8日 grade occupies 28% and rest comes under unclassified categories. Iron ore in the size range of 8 mm to 0.15 mm are designated as fines, whereas, the ore below 0.15 mm are known as slime. Major resources of hematite iron ore are located in Orissa (3,789 million tons (33%)), Jharkhand (3,044 million tons (27%)),

Iron Ore Tailings: Characterization and Applications

2021年7月26日 IOT generated in the iron ore beneficiation process depends mainly on the mineralogy of the processed rock, the nature of the processing fluids used in the target minerals, the efficiency of the processing, and the degree of weathering before the storage in the dam.29 During the exploitation of iron ore, crushing rocks

Mineralogical and Chemical Characterization of Low Grade

2019年4月11日 The consumption of iron ore has increased rapidly over the past decade due to the tremendous growth of iron and steel industry. The depletion of high grade iron ore resources make it inevitable to utilize the existing low grade iron ores/fines/tailings with effective beneficiation to meet the present specification and demand. Enormous amounts

COLUMN FLOTATION FOR THE BENEFICIATION OF IRON

2011年11月8日 grade iron ore to produce quality raw material would play a key role in future which is a fact acknowledged by the iron and steel industry. [1,2] India is bestowed with rich iron ore reserves in the form of hematite and magnetite. Most of the iron ore mines produce hematite ores and have washing plants to produce lumps as well as fines.

Innovative Technique to Generate Saleable Iron Ore Fines

on ultra-fines recovery plant tailings revels that, there was an escape of martite, goethite and hematite in tailings. Again an attempt was made in 2010 by conducting in-house and external study to recover escaped iron ore bearing minerals from ultra-fines recovery plant on line tailings using column flotation

(PDF) iron ore benefication d.p chakravarthy

View PDF. Download Free PDF. Scientific part of iron ore beneficiation project proposal Iron ore beneficiation is a process which removes the gang particle like Alumina, Silica from the Iron Ore. Basically it separates Fe2O3 or Fe3O4 from other impurities in the iron ore. In this process the Fe content is improved to maximum possible extent.

CSIR IMMT Mineral Processing Research Areas

2 之 Innovative research to utilize lean and complex ores. IMMTDevelopment of advanced equipments in mineral processing. IMMTDevelopment of processes to recover valuables from wastes and by-products. IMMTFlow sheet development to beneficiate low and medium grade ores. IMMTCharacterization and resource evaluation of ores and coal.

حتى كسارة المطرقة الحبيبية للفحم بسعر رائع

كسارة ميسين للباتو

مخطط تدفق عملية الدوائر المتكاملة

used mining crusher in uzbekistan for sale

ورأى عصابة الرخام للبيع

مطحنة الحجر في جنوب أفريقيا

10 طن للساعة تكسير الذهب مطحنة الكرة

الحجر ومحطم ملموسة-فرز الحصى للبيع ومحطم

british coal mining company

gold mining operations in south africa

اسعار ماكينه تطحن قش الارز

杏壳活性炭生产厂家-果壳活性炭 果壳活性炭 果壳活性炭厂家

石头和玻璃混合加工机械

لائحة شركة مطاحن شرق الدلتا

flotation costs-What is floatation cost

آلة مطحنة الكرة للبيع مصر

طحن seekpart آلة-

grinding machine states-Metal Industry Grinding Machines

طحن مطحنة الشركة المصنعة قذيفة الخزان الخارجي

قائمة مشتري خام الحديد حول العالم

construction methods and equipment managment ppt-Construction Site Safety

تأثير كسارة مقابل كسارة المحمول

تجهيز خط إنتاج خام الكالسيت

learnership in surface mining

المياه ثلاثة مطارق رأس دبوس تشنغدو

posho mill distributors in kenya

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20