الحار منتجات

ملكنا الإخبارية

conveyor unit weighingBelt Conveyors for Bulk Materials Practical Calculations

Bulk Material Handling: ConveyorsEquipment

1 From the moment the first stone breaks underground, reliable conveyor systems support the handling of bulk goods. As a manufacturer and system partner, the BEUMER

进一步探索Bulk material handling systems all you need to knowBelt Conveyors for Bulk Materials, 7th ed. Chapter 146 Bulk Material Handling Jobs Shine8 Basic Types of Conveyor Belts and Their Applications7 Types of Conveyors and Their Functions YaleTools根据热度为您推荐•反馈

Materials conveyors: A guide for specifying belt conveyor

Understanding Key TerminologiesThe Design ProcessConveyor Belt Dimension, Capacity and SpeedRoller Diameter and RpmBelt Power, Tensions and Motor SpecificationIdler Spacing

Capacity (C) describes the rate at which the bulk material is being conveyed by the belt. It is measured in ton per hour (TPH) or kg/hr.Lump size describes the maximum dimensions of the bulk material being conveyed. For instance, the lump size of a steel grit is its diameter.Troughing angle describes the angle the belt forms on the carrying side while running over id Capacity (C) describes the rate at which the bulk material is being conveyed by the belt. It is measured in ton per hour (TPH) or kg/hr.Lump size describes the maximum dimensions of the bulk material being conveyed. For instance, the lump size of a steel grit is its diameter.Troughing angle describes the angle the belt forms on the carrying side while running over idlerrollers. Belts are troughed to allow the conveyor load and to transport materials. Common troughing a...Surcharge angle describes the angle that the surface of the material makes with the horizontal when it is at rest on a moving conveyor belt.展开选择时,新内容将添加到焦点当区域上方在insights.globalspec上查看更多信息

Conveyors Capacities Engineering ToolBox

2023年3月3日 Typical Conveyor Capacity. 1 in = 25.4 mm. 1 ft3/h = 0.028 m3/h. 1 ft/min = 5.08 x 10-3 m/s. The product cross sectional area is defined by the idler trough shape

Automated Conveyor Systems, Flexible Conveyors Flexlink

PLASTIC CHAIN CONVEYORS. MODULAR BELT CONVEYORS. PUCK HANDLING. PALLET CONVEYORS. SPIRAL CONVEYORS. WEDGE CONVEYORS. PCB

Belt Conveyors for Bulk Materials, 7th ed.

A combination of preventative and predictive maintenance programs will help ensure maximum availability and component life. A well-maintained conveyor system should be able to consistently operate with 90%

(PDF) BELT CONVEYOR ResearchGate

2022年4月14日 Abstract. Belt conveyor is a material transfer equipment that uses a belt (tire belt) as a transfer tool used to move unit loads (unit loads) and rainfall loads along a

[PDF]

Belt Conveyors Khulna University Of Engineering

2021年3月7日 Drive Unit: The drive unit is of the usual type, commonly supplied with a reducing gear. It’s duty to protect gear against breakages in case of an accidental

(PDF) CEMA-Belt Conveyors for Bulk Materials

CEMA-Belt Conveyors for Bulk Materials. Carolina García Bravo. Norma CEMA para correas trasportadoras.

Measuring Bulk Solids on a Conveyor

2015年10月2日 Measuring Bulk Solids on a Conveyor. Figure 1. Conveyor belts are often used to move materials in mining and other applications, and a measurement of the amount of material conveyed is a key control

7 Types of Conveyors and Their Functions YaleTools

This material transfer can also be used for mixing and stirring. 6. Slat or Apron Conveyor. Slat Conveyor. Slat conveyors are usually used to move large capacity material objects.

Materials conveyors: A guide for specifying belt conveyor

2021年1月26日 The first step in the design of a belt conveyor with a specified conveyor capacity is to determine the speed and width of the belt. The magnitude of the belt speed can be determined using: equation. Where: C = Conveyor capacity. r = Material density (kg/m3) V = Belt speed (m/s) A = Conveyor’s belt cross-sectional area.

Automated Conveyor Systems, Flexible Conveyors Flexlink

PLASTIC CHAIN CONVEYORS. MODULAR BELT CONVEYORS. PUCK HANDLING. PALLET CONVEYORS. SPIRAL CONVEYORS. WEDGE CONVEYORS. PCB HANDLING. COMPONENTS AND PARTS. BELTS AND CHAINS.

Belt Conveyors for Bulk Materials, 7th ed.

A combination of preventative and predictive maintenance programs will help ensure maximum availability and component life. A well-maintained conveyor system should be able to consistently operate with 90%

(PDF) BELT CONVEYOR ResearchGate

2022年4月14日 Abstract. Belt conveyor is a material transfer equipment that uses a belt (tire belt) as a transfer tool used to move unit loads (unit loads) and rainfall loads along a straight line (horizontal

Conveyor Units The UK's Largest Manufacturer

Conveyor Units Ltd is built on five decades of engineering development. We serve partners and customers from both the public and private sectors, including system integrators, other engineering companies and OEMs.

[PDF]

VERTICAL CONVEYORS FOR BULK MATERIALS

2007年2月12日 n unit are the main components. In figure 7 the top deflection-unit with. shown. The conveyor drives and the discharge of the conveyor are shown in figure 8. The discharge station is equipped with a belt cleaner and a conveyor for the material, which is situated underneath the Flexowell-belt. Figure 5. Vertical conveyor for Saidanha . Steel

(PDF) CEMA-Belt Conveyors for Bulk Materials

CEMA-Belt Conveyors for Bulk Materials. Carolina García Bravo. Norma CEMA para correas trasportadoras.

[PDF]

Belt Conveyors Khulna University Of Engineering

2021年3月7日 Drive Unit: The drive unit is of the usual type, commonly supplied with a reducing gear. It’s duty to protect gear against breakages in case of an accidental overloads Take Up Unit: The take up chainflight conveyors is of the screw or spring and screw type. The adjustment length should be nit less than 1.6 times the chain pitch.

Calculating the Speed of a Conveyor System Technical

2021年11月7日 Figure 3. Video used courtesy of ATS Automation. Servo-driven Conveyor. A servo-driven conveyor will likely start and stop as needed and move to a precise position, similar to an indexing table. With a servo motor driving the conveyor, the speed is only limited by the product’s weight and the product’s stability. If moving a liquid, the

Belt Conveyors for Bulk Materials Fifth Edition PDF

Belt Conveyors for Bulk Materials Fifth Edition PDF Read more about conveyor, pulley, idler, idlers, motor and loading.

ISO 53.040.10 Conveyors International Organization

90.93. ISO/TC 101. ISO 2406:1974. Continuous mechanical handling equipment — Mobile and portable conveyors — Constructional specifications. 90.93. ISO/TC 101. ISO 5041:1977. Continuous mechanical handling equipment for unit loads — Crate-carrying chain conveyors having biplanar chains for flat-bottomed unit loads — Safety code. 95.99.

[PDF]

Faculty of Engineering Technology

2016年4月15日 1.3Miedema Conveyor 65 The Miedema Conveyor 65 (MC 65) is a conveyor belt used for transportation of products for storage, see gure 1.3. The 65 indicates the length in dm, so the total length is 6.5 m. During the storage it is desired to check the total amount of product stored and the current ow rate to see if the

Belt Conveyors for Bulk Materials, 7th ed.

A combination of preventative and predictive maintenance programs will help ensure maximum availability and component life. A well-maintained conveyor system should be able to consistently operate with 90%

Bulk Handling Calculator Van der Graaf

Bulk Handling CALCULATOR. This program provides general estimates for conveyor power requirements. It does not take into account a variety of factors including, but not limited to, various losses, efficiencies, and drive

Conveyor Units The UK's Largest Manufacturer

Conveyor Units Ltd is built on five decades of engineering development. We serve partners and customers from both the public and private sectors, including system integrators, other engineering companies and OEMs.

[PDF]

VERTICAL CONVEYORS FOR BULK MATERIALS

2007年2月12日 n unit are the main components. In figure 7 the top deflection-unit with. shown. The conveyor drives and the discharge of the conveyor are shown in figure 8. The discharge station is equipped with a belt cleaner and a conveyor for the material, which is situated underneath the Flexowell-belt. Figure 5. Vertical conveyor for Saidanha . Steel

(PDF) CEMA-Belt Conveyors for Bulk Materials

CEMA-Belt Conveyors for Bulk Materials. Carolina García Bravo. Norma CEMA para correas trasportadoras.

[PDF]

Belt Conveyors Khulna University Of Engineering

2021年3月7日 Drive Unit: The drive unit is of the usual type, commonly supplied with a reducing gear. It’s duty to protect gear against breakages in case of an accidental overloads Take Up Unit: The take up chainflight conveyors is of the screw or spring and screw type. The adjustment length should be nit less than 1.6 times the chain pitch.

Belt Conveyors for Bulk Materials Calculations by

2015年6月3日 Belt Conveyors for Bulk Materials Calculations by Published by Guset User,2015-06-03 15:33:03 Description: belt speed, lump size/material density, maintenance, environment, temperature, and the proper CEMA series of idler to handle the maximum calculated idler load.

大规格钢棒去哪里研磨

تقديرات تكلفة مشروع طحن الكرة المصغرة

limestone mining cursher in thailand

سحق المعدات محجر الحجر-سحق الحجر المعدات

الشركة المصنعة للكسارة المتنقلة المثبتة على المسار

الكرة مطحنة سعر الجزائر

كسارة تعدين الأنتيمون

أسعار مطحنة الكرة وللبيع ليتوانيا

new zealand spare parts-HP Spare Parts In New Zealand

معدات التنقيط في فرن النفق

understanding cement book torrents

معدات تجهيز الجرانيت مصر

متناهية الصغر توربو مطحنة

طحن الآلات المستخدمة في جنوب أفريقيا كسارة للبيع

shanghai small scale ball mill supplier

الجرانيت الطواحين

اصول عملیاتی ساخت سنگ شکن رول

وتفجير منجم خام الحديد

gold ore crushing system in the uzbekistan

كوستاريكا العلامة التجارية الجديدة والعالية الموثوق بها مواصفات كسارة الحجر الفك

حول الكسارات الفكية

كسارة خام النحاس السوداني

مطحنة التعدين الكرة الصغيرة للبيع

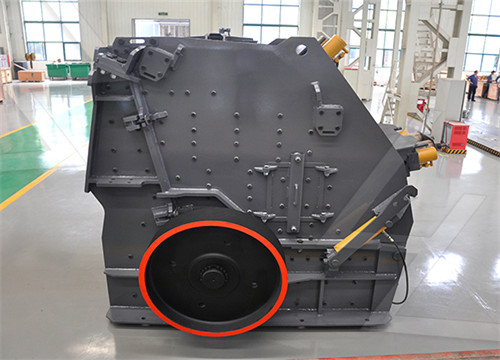

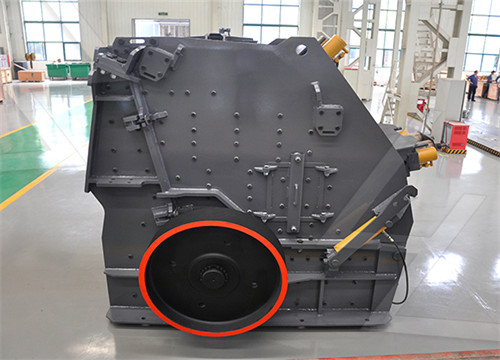

هيكل كسارة الصدم

مطحنة الجذع powertek

المشابك الحزام الناقل istol

Materials conveyors: A guide for specifying belt conveyor

Understanding Key TerminologiesThe Design ProcessConveyor Belt Dimension, Capacity and SpeedRoller Diameter and RpmBelt Power, Tensions and Motor SpecificationIdler Spacing

Capacity (C) describes the rate at which the bulk material is being conveyed by the belt. It is measured in ton per hour (TPH) or kg/hr.Lump size describes the maximum dimensions of the bulk material being conveyed. For instance, the lump size of a steel grit is its diameter.Troughing angle describes the angle the belt forms on the carrying side while running over id Capacity (C) describes the rate at which the bulk material is being conveyed by the belt. It is measured in ton per hour (TPH) or kg/hr.Lump size describes the maximum dimensions of the bulk material being conveyed. For instance, the lump size of a steel grit is its diameter.Troughing angle describes the angle the belt forms on the carrying side while running over idlerrollers. Belts are troughed to allow the conveyor load and to transport materials. Common troughing a...Surcharge angle describes the angle that the surface of the material makes with the horizontal when it is at rest on a moving conveyor belt.展开选择时,新内容将添加到焦点当区域上方在insights.globalspec上查看更多信息

Conveyors Capacities Engineering ToolBox

2023年3月3日 Typical Conveyor Capacity. 1 in = 25.4 mm. 1 ft3/h = 0.028 m3/h. 1 ft/min = 5.08 x 10-3 m/s. The product cross sectional area is defined by the idler trough shape

Automated Conveyor Systems, Flexible Conveyors Flexlink

PLASTIC CHAIN CONVEYORS. MODULAR BELT CONVEYORS. PUCK HANDLING. PALLET CONVEYORS. SPIRAL CONVEYORS. WEDGE CONVEYORS. PCB

Belt Conveyors for Bulk Materials, 7th ed.

A combination of preventative and predictive maintenance programs will help ensure maximum availability and component life. A well-maintained conveyor system should be able to consistently operate with 90%

(PDF) BELT CONVEYOR ResearchGate

2022年4月14日 Abstract. Belt conveyor is a material transfer equipment that uses a belt (tire belt) as a transfer tool used to move unit loads (unit loads) and rainfall loads along a

Belt Conveyors Khulna University Of Engineering

2021年3月7日 Drive Unit: The drive unit is of the usual type, commonly supplied with a reducing gear. It’s duty to protect gear against breakages in case of an accidental

(PDF) CEMA-Belt Conveyors for Bulk Materials

CEMA-Belt Conveyors for Bulk Materials. Carolina García Bravo. Norma CEMA para correas trasportadoras.

Measuring Bulk Solids on a Conveyor

2015年10月2日 Measuring Bulk Solids on a Conveyor. Figure 1. Conveyor belts are often used to move materials in mining and other applications, and a measurement of the amount of material conveyed is a key control

7 Types of Conveyors and Their Functions YaleTools

This material transfer can also be used for mixing and stirring. 6. Slat or Apron Conveyor. Slat Conveyor. Slat conveyors are usually used to move large capacity material objects.

Materials conveyors: A guide for specifying belt conveyor

2021年1月26日 The first step in the design of a belt conveyor with a specified conveyor capacity is to determine the speed and width of the belt. The magnitude of the belt speed can be determined using: equation. Where: C = Conveyor capacity. r = Material density (kg/m3) V = Belt speed (m/s) A = Conveyor’s belt cross-sectional area.

Automated Conveyor Systems, Flexible Conveyors Flexlink

PLASTIC CHAIN CONVEYORS. MODULAR BELT CONVEYORS. PUCK HANDLING. PALLET CONVEYORS. SPIRAL CONVEYORS. WEDGE CONVEYORS. PCB HANDLING. COMPONENTS AND PARTS. BELTS AND CHAINS.

Belt Conveyors for Bulk Materials, 7th ed.

A combination of preventative and predictive maintenance programs will help ensure maximum availability and component life. A well-maintained conveyor system should be able to consistently operate with 90%

(PDF) BELT CONVEYOR ResearchGate

2022年4月14日 Abstract. Belt conveyor is a material transfer equipment that uses a belt (tire belt) as a transfer tool used to move unit loads (unit loads) and rainfall loads along a straight line (horizontal

Conveyor Units The UK's Largest Manufacturer

Conveyor Units Ltd is built on five decades of engineering development. We serve partners and customers from both the public and private sectors, including system integrators, other engineering companies and OEMs.

VERTICAL CONVEYORS FOR BULK MATERIALS

2007年2月12日 n unit are the main components. In figure 7 the top deflection-unit with. shown. The conveyor drives and the discharge of the conveyor are shown in figure 8. The discharge station is equipped with a belt cleaner and a conveyor for the material, which is situated underneath the Flexowell-belt. Figure 5. Vertical conveyor for Saidanha . Steel

(PDF) CEMA-Belt Conveyors for Bulk Materials

CEMA-Belt Conveyors for Bulk Materials. Carolina García Bravo. Norma CEMA para correas trasportadoras.

Belt Conveyors Khulna University Of Engineering

2021年3月7日 Drive Unit: The drive unit is of the usual type, commonly supplied with a reducing gear. It’s duty to protect gear against breakages in case of an accidental overloads Take Up Unit: The take up chainflight conveyors is of the screw or spring and screw type. The adjustment length should be nit less than 1.6 times the chain pitch.

Calculating the Speed of a Conveyor System Technical

2021年11月7日 Figure 3. Video used courtesy of ATS Automation. Servo-driven Conveyor. A servo-driven conveyor will likely start and stop as needed and move to a precise position, similar to an indexing table. With a servo motor driving the conveyor, the speed is only limited by the product’s weight and the product’s stability. If moving a liquid, the

Belt Conveyors for Bulk Materials Fifth Edition PDF

Belt Conveyors for Bulk Materials Fifth Edition PDF Read more about conveyor, pulley, idler, idlers, motor and loading.

ISO 53.040.10 Conveyors International Organization

90.93. ISO/TC 101. ISO 2406:1974. Continuous mechanical handling equipment — Mobile and portable conveyors — Constructional specifications. 90.93. ISO/TC 101. ISO 5041:1977. Continuous mechanical handling equipment for unit loads — Crate-carrying chain conveyors having biplanar chains for flat-bottomed unit loads — Safety code. 95.99.

Faculty of Engineering Technology

2016年4月15日 1.3Miedema Conveyor 65 The Miedema Conveyor 65 (MC 65) is a conveyor belt used for transportation of products for storage, see gure 1.3. The 65 indicates the length in dm, so the total length is 6.5 m. During the storage it is desired to check the total amount of product stored and the current ow rate to see if the

Belt Conveyors for Bulk Materials, 7th ed.

A combination of preventative and predictive maintenance programs will help ensure maximum availability and component life. A well-maintained conveyor system should be able to consistently operate with 90%

Bulk Handling Calculator Van der Graaf

Bulk Handling CALCULATOR. This program provides general estimates for conveyor power requirements. It does not take into account a variety of factors including, but not limited to, various losses, efficiencies, and drive

Conveyor Units The UK's Largest Manufacturer

Conveyor Units Ltd is built on five decades of engineering development. We serve partners and customers from both the public and private sectors, including system integrators, other engineering companies and OEMs.

VERTICAL CONVEYORS FOR BULK MATERIALS

2007年2月12日 n unit are the main components. In figure 7 the top deflection-unit with. shown. The conveyor drives and the discharge of the conveyor are shown in figure 8. The discharge station is equipped with a belt cleaner and a conveyor for the material, which is situated underneath the Flexowell-belt. Figure 5. Vertical conveyor for Saidanha . Steel

(PDF) CEMA-Belt Conveyors for Bulk Materials

CEMA-Belt Conveyors for Bulk Materials. Carolina García Bravo. Norma CEMA para correas trasportadoras.

Belt Conveyors Khulna University Of Engineering

2021年3月7日 Drive Unit: The drive unit is of the usual type, commonly supplied with a reducing gear. It’s duty to protect gear against breakages in case of an accidental overloads Take Up Unit: The take up chainflight conveyors is of the screw or spring and screw type. The adjustment length should be nit less than 1.6 times the chain pitch.

Belt Conveyors for Bulk Materials Calculations by

2015年6月3日 Belt Conveyors for Bulk Materials Calculations by Published by Guset User,2015-06-03 15:33:03 Description: belt speed, lump size/material density, maintenance, environment, temperature, and the proper CEMA series of idler to handle the maximum calculated idler load.

大规格钢棒去哪里研磨

تقديرات تكلفة مشروع طحن الكرة المصغرة

limestone mining cursher in thailand

سحق المعدات محجر الحجر-سحق الحجر المعدات

الشركة المصنعة للكسارة المتنقلة المثبتة على المسار

الكرة مطحنة سعر الجزائر

كسارة تعدين الأنتيمون

أسعار مطحنة الكرة وللبيع ليتوانيا

new zealand spare parts-HP Spare Parts In New Zealand

معدات التنقيط في فرن النفق

understanding cement book torrents

معدات تجهيز الجرانيت مصر

متناهية الصغر توربو مطحنة

طحن الآلات المستخدمة في جنوب أفريقيا كسارة للبيع

shanghai small scale ball mill supplier

الجرانيت الطواحين

اصول عملیاتی ساخت سنگ شکن رول

وتفجير منجم خام الحديد

gold ore crushing system in the uzbekistan

كوستاريكا العلامة التجارية الجديدة والعالية الموثوق بها مواصفات كسارة الحجر الفك

حول الكسارات الفكية

كسارة خام النحاس السوداني

مطحنة التعدين الكرة الصغيرة للبيع

هيكل كسارة الصدم

مطحنة الجذع powertek

المشابك الحزام الناقل istol

حول لدينا

تأسست شركة Henan Lrate للعلوم والتكنولوجيا المحدودة التي تصنع معدات التكسير والطحن الكبيرة والمتوسطة الحجم في عام 1987. وهي شركة مساهمة حديثة مع البحث والتصنيع والمبيعات معًا.

على مدار أكثر من 30 عامًا ، تلتزم شركتنا بنظام الإدارة العلمية الحديث والتصنيع الدقيق والريادة والابتكار. الآن أصبحت LIMING رائدة في صناعة تصنيع الآلات المحلية والخارجية.

2021/07/20

2021/07/20